Iwaki, Japan – December 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DrillForce-Meister series, now featuring the wear-resistant AH9130 grade for intermediate diameter heads, enabling extended tool life and stable, high-precision drilling with 13 new diameter sizes.

Challenges and Trends

In fields such as structural steel for construction, construction machinery components, and automotive parts, high-precision and stable hole drilling is essential. However, with conventional tools, tool life tends to shorten when machining conditions are intensified, leading to issues in productivity and cost-efficiency. In many cases, especially when compared with competing products, concerns remain regarding tool longevity. As a result, there is a strong demand for tools that offer both long life and high efficiency. Across the market, achieving both reduced machining costs and improved productivity has become a critical challenge.

Product Overview

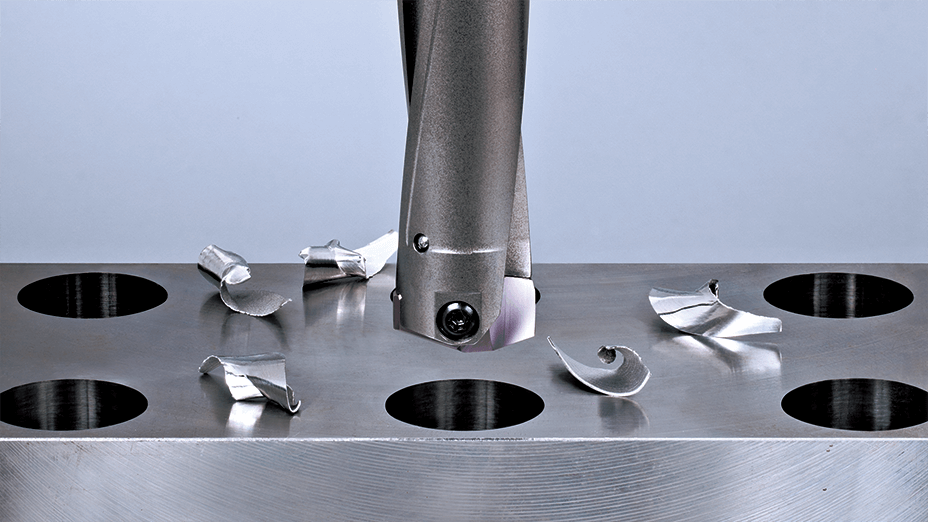

DrillForce-Meister is a head-exchangeable drill specially designed for large-diameter hole machining. Its unique clamping structure and two-flute design deliver high precision and productivity. The drill head can be replaced without removing the tool from the machine, contributing to improved work efficiency and extended tool life.

Benefits and Features

Long tool life and high-efficiency machining with the highly wear-resistant grade “AH9130”

– Specialized PVD coating for P/M/K materials delivers excellent wear resistance

– Ensures stable tool life even under high-speed and high-efficiency cutting conditions

– Reduces tool change frequency, contributing to shorter setup time and improved productivity

Cost reduction and improved operational efficiency through compatibility with existing bodies

– Directly mountable on existing DrillForce-Meister bodies, enabling tool inventory consolidation

– Head replacement possible without fully removing the screw, simplifying setup operations

– Screw-clamp mechanism prevents head loosening during machining, supporting stable cutting