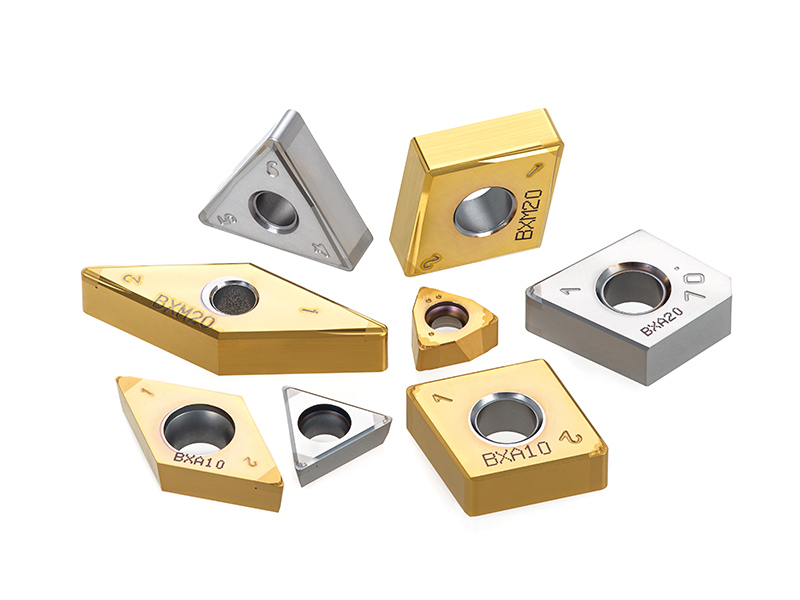

CBN inserts with integrated chipbreaker for improved hard turning productivity

CBN inserts with chipbreaker ideal for carburized layer removal and finishing hardened steel

Applications & Features

Applications

Features

HS chipbreaker

Optimized chipbreaker design for excellent chip control during hard turning at aggressive conditions

- Designed for high feed machining.

- Provides excellent chip control for a wide range of D.O.C. and feed rates.

- Edge preparation is designed to prevent catastrophic failure.

HP chipbreaker

Designed for finish machining of hardened parts with close tolerances

- Optimized chipbreaker geometry significantly reduces cutting force imposed on the cutting edge, ensuring long tool life.

- The edge preparation is designed to generate low cutting force, providing chatter-free machining and close tolerances.

- The built-in wiper yields excellent surface quality and good chip control.

HF and HM chipbreakers

- Suited for hard turning applications requiring great D.O.C. such as carburized layer removal.

- Effective chip breaking is possible for a wide range of hard materials.

- BXA20 and BXM20 CBN grade inserts are available for aggressive cutting depths.

Inserts & Grades

Inserts

HP chipbreaker

- Designed for finish machining of hardened parts with close tolerances

HS chipbreaker

- Optimized chipbreaker design for excellent chip control during hard turning at aggressive conditions

HF chipbreaker

- Suited for hard turning applications requiring great D.O.C. such as carburized layer removal

HM chipbreaker

- Suited for hard turning applications requiring great D.O.C. such as carburized layer removal

Main Grades

BM05M

![]()

- First choice for high speed continuous cuts.

- For Vc = 350 m/min or less.

BXA10

![]()

- First choice for continuous to light interrupted cuts.

- For cutting speed = 230 m/min or less.

BXA20

![]()

- Versatile grade from continuous to heavy interrupted cuts.

- For Vc = 180 m/min or less.

Practical examples

Example #1

| Part: | Road roller (heavy equipment) |

| Material: | S45C / C45 (58HRC) |

| Insert: | 3QP-TNGM160408-HS |

| Grade: | BXM20 |

| Cutting conditions: | Vc = 180 (m/min) f = 0.15 (mm/rev) ap = 0.25 (mm) Coolant: Wet |

Example #2

| Part: | Input shaft |

| Material: | SCM420 / 18CrMo4 (58 – 60HRC) |

| Insert: | 2QP-CNGM120408-HS |

| Grade: | BXM10 |

| Cutting conditions: | Vc = 113 – 238 (m/min) f = 0.17 (mm/rev) ap = 0.25 (mm) Coolant: Wet |

Example #3

| Part: | Bevel gear |

| Material: | SCM420 / 18CrMo4 (58HRC) |

| Insert: | 2QP-CNGM120408-HP |

| Grade: | BXA20 |

| Cutting conditions: | Vc = 160 (m/min) f = 0.1 (mm/rev) ap = 0.15 (mm) Coolant: Wet |

Standard cutting conditions

| ISO | Chipbreaker | Grade | Work condition | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|---|---|

| HP | BXA10 | Continuous | 120 – 350 | 0.03 – 0.22 | 0.03 – 0.25 | |

| HP | BXM10 | Continuous | 120 – 350 | 0.03 – 0.22 | 0.03 – 0.25 | |

| HP | BXA20 | Light interrupted | 70 – 180 | 0.03 – 0.22 | 0.03 – 0.25 | |

| HS | BXA10 | Continuous | 120 – 350 | 0.1 – 0.35 | 0.05 – 0.3 | |

| HS | BXA20 | Light interrupted | 70 – 180 | 0.1 – 0.35 | 0.05 – 0.3 | |

| HF | BXA20 | Removing of carburized layer |

70 – 180 | 0.3 – 1 | 0.05 – 0.3 | |

| HF | BXM20 | Removing of carburized layer |

70 – 180 | 0.3 – 0.8 | 0.05 – 0.3 | |

| HM | BXA20 | Removing of carburized layer |

70 – 180 | 0.5 – 1 | 0.05 – 0.3 | |

| HM | BXM20 | Removing of carburized layer |

70 – 180 | 0.5 – 1 | 0.05 – 0.3 |

For more information about this product, visit our online e-catalog or download the product report: