Y-axis turning tool with PSC connection for multitasking machines

ADD high productivity combined with multiple processes & tools into a single operation

Applications & Features

Applications

Features

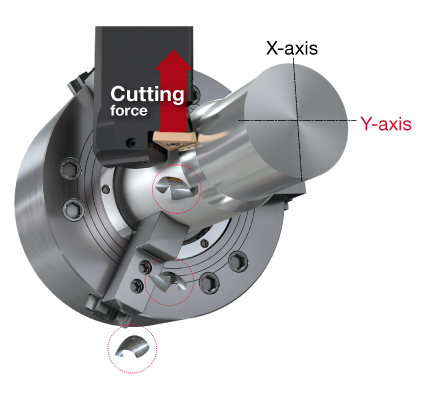

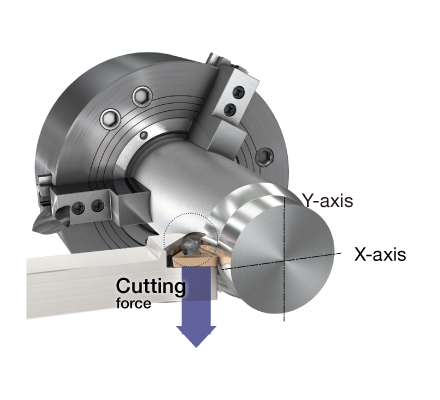

1. Y-axis machining benefits

- The cutting force vector is directed in the longitudinal axis of the tool, resulting in higher stability and minimized vibration

- No chip entanglements, chips are directed down and away from the workpiece and toolholder

Conventional X-axis feed

2. PSC Y-axis tool for multitasking machines

- High rigidity design PSC tool body and through-coolant supply for tool life stability

3. Y-axis tooling concept providing small entry angle for high productivity

- T-type : Max feed rate 2 mm/rev

- D-type : Max feed rate 1.2 mm/rev

4. Tooling image of Y-axis orientation and applying high feed back turning

T-type for medium cutting operation

- Thanks to its high-feed geometry, AddY-axisTurn insert provides high productivity

- Y-axis tool orientation allows both sides of the cutting edge to be used, providing stable and long tool life

D-type for finishing and profiling operation

- AddY-axisTurn allows a precision workpiece completion with a single tool setup

- No interference with the tailstock

- Eliminates chip entanglement, promoting fully automated manufacturing

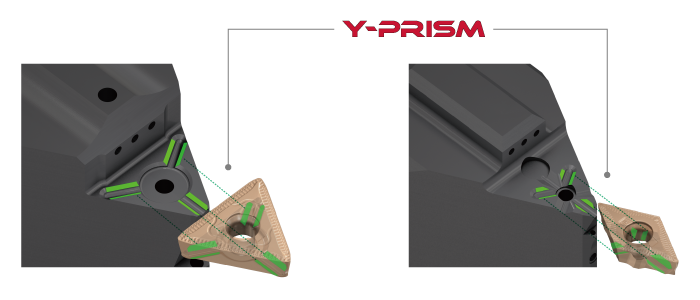

5. Secure insert clamping system

- Y-PRISM’s safe lock design has a rail on the toolholder and matching slot on the insert for tight interlocking and secure clamping.

- Prevents the cutting forces from affecting the insert position in any direction and ensures high stability.

Inserts & Grades

Inserts

2D-DCMT

- D-type for finishing and profiling operation

3C-TCMT

- T-type for medium cutting operation

Main Grades

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

Toolholders

External turning

AddY-axisTurn Toolholders for 2D-DCMT inserts

Screw-on Y-axis turning toolholder with PSC connection

External turning

AddY-axisTurn Toolholders for 3C-TCMT inserts

Screw-on Y-axis turning toolholder with PSC connection

Standard cutting conditions

| ISO | Operation | Chipbreaker | Grade | Cutting speed |

|---|---|---|---|---|

| Vc (m/min) | ||||

|

Finishing | ZF | T9215 | 150 – 400 |

| Medium to heavy cutting | TM | T9215 | 150 – 400 | |

|

Finishing | ZF | T9215 | 100 – 250 |

| Medium to heavy cutting | TM | T9215 | 100 – 250 | |

|

Finishing | ZF | T9215 | 140 – 500 |

| Medium to heavy cutting | TM | T9215 | 140 – 500 |

For more information about this product, visit our online e-catalog or download the product report: