6-corner inserts for high versatility, economy and productivity

Front Turning, Back Turning, Profiling, and Face Turning with ONE SINGLE TOOL

Applications & Features

Applications

Features

1. Two types of corner and cutting edge angles for versatile applications

Double-sided 6-corner insert with 80° or 35° corner angle

- Back (pull) turning: High feed designed cutting edge improves productivity about 200% higher than existing ISO tools with no need for special programming.

- Front (push) turning: Same machining process is available using the same cutting edge angle as standard ISO tools.

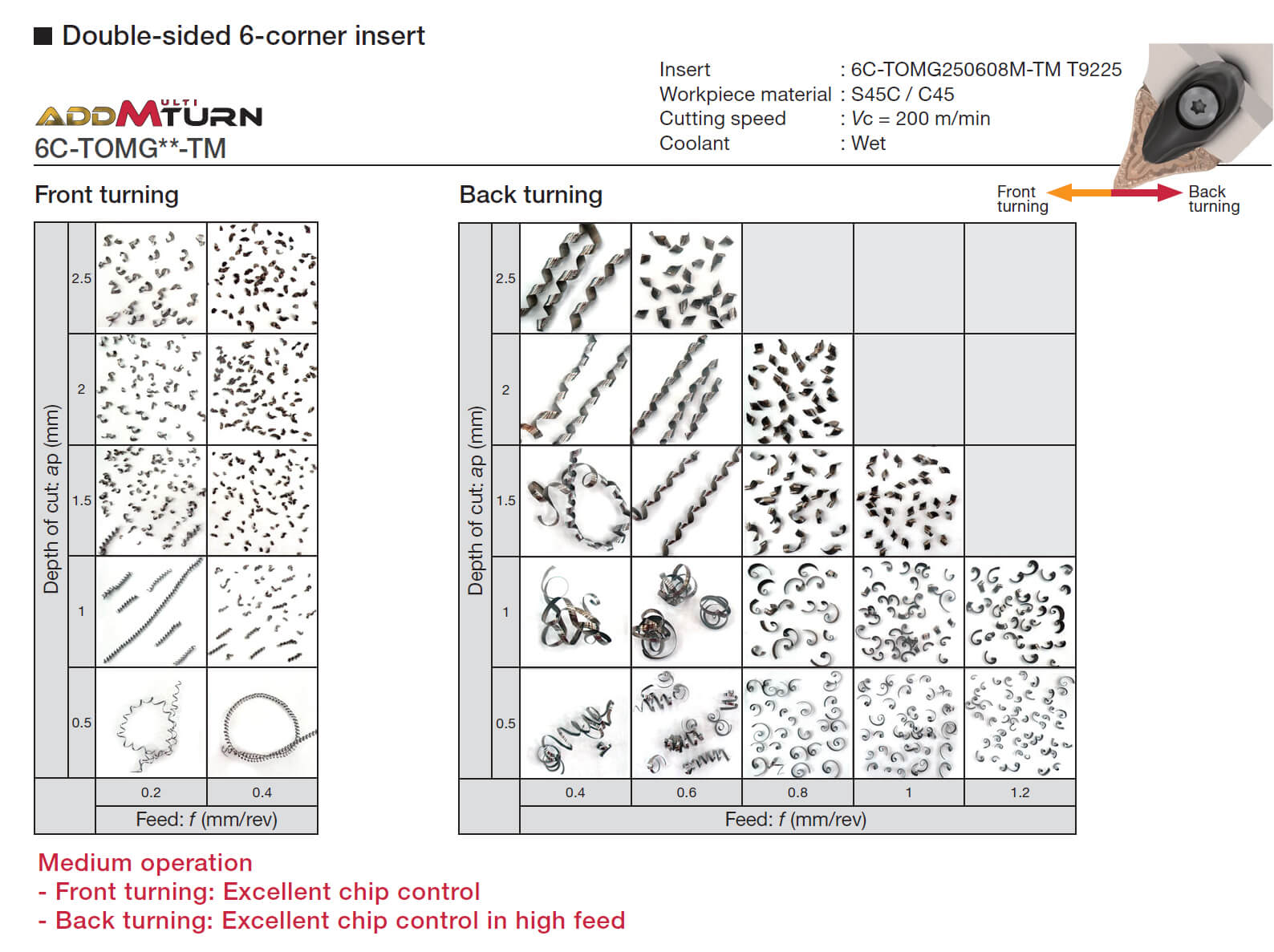

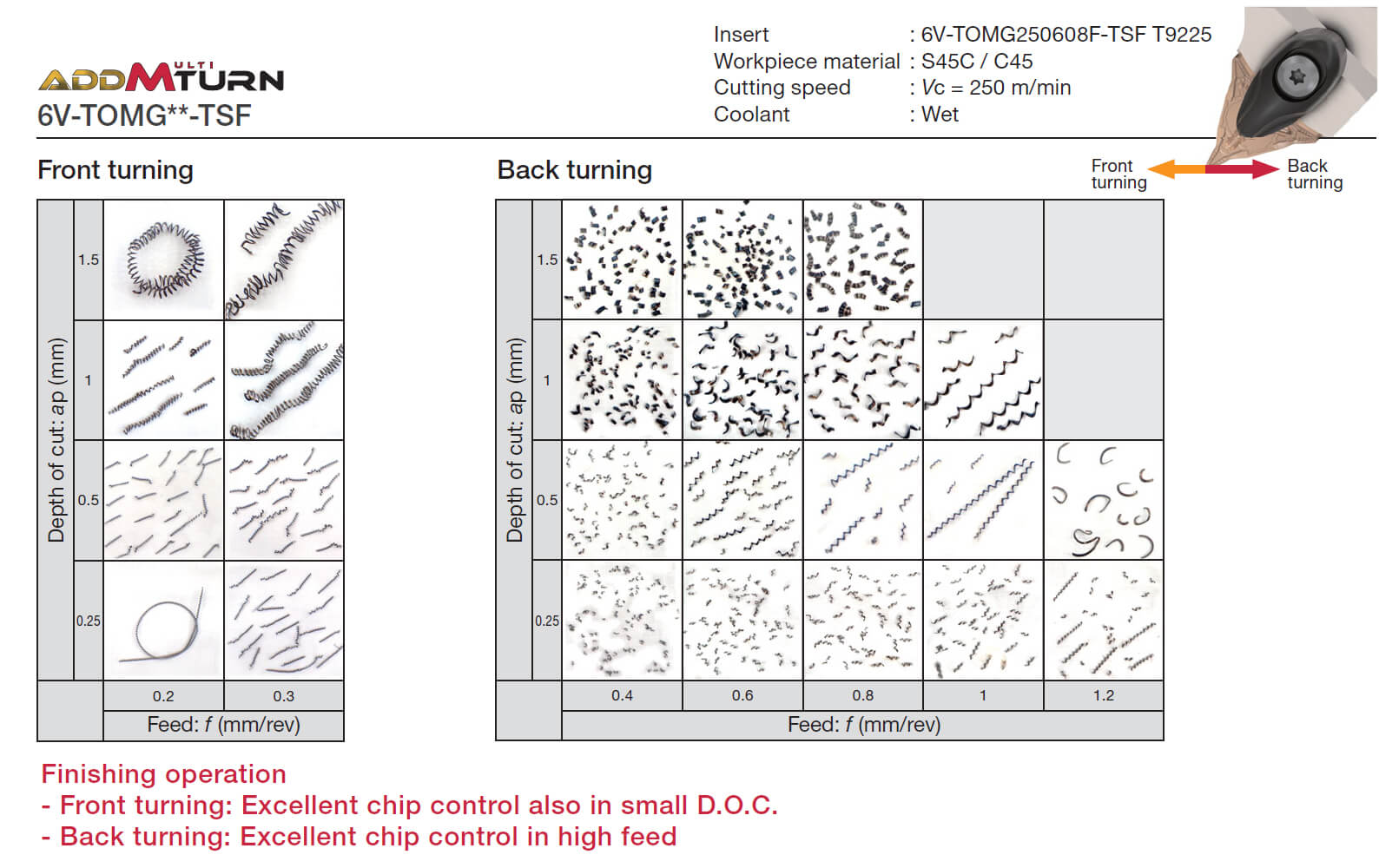

2.Chip control

Inserts & Grades

Inserts

3C-TCMT

- Positive 7 deg relief angle, M class, triangular insert

6C-TOMG

- Negative relief ang., M class, 80 deg corner angle insert

6V-TOMG

- Negative relief ang., M class, 35 deg corner angle insert

Grades

AH8015

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

T9225

![]()

![]()

![]()

- First choice for roughing to medium cutting

- High fracture resistance

T9215

![]()

![]()

![]()

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

Toolholders

Practical examples

Example #1

| Part: | Turbine shaft |

| Material: | SCr420 / 20Cr4 |

| Toolholder: | ATXOL2525M25-A |

| Insert: | 6C-TOMG250608M-TM |

| Grade: | T9215 |

| Cutting conditions: | Vc = 147 (m/min) Face turning: f = 0.35 (mm/rev) ap = 1 – 2 (mm) External turning: f = 0.5 (mm/rev) ap = 0.5 (mm)Coolant: Wet (External coolant) Application: Face turning, External turning |

Example #2

| Part: | Gear part |

| Material: | S25C / C25 |

| Toolholder: | ATXOR2525M25-A |

| Insert: | 6V-TOMG250604F-TSF |

| Grade: | T9215 |

| Cutting conditions: | Vc = 200 (m/min) Roughing : f = 0.6 (mm/rev) x 2 passes Finishing : f = 0.1 (mm/rev) x 1 pass ap = 0.5 (mm) x 3 passesCoolant: Wet (External coolant) Application: External turning |

Standard cutting conditions

Double-sided 6-corner insert

| ISO | Operation | Chipbreaker | Grade | Depth of cut: ap (mm) | Feed: f (mm/rev) | Cutting speed | ||

|---|---|---|---|---|---|---|---|---|

| Front turning | Back turning | Front turning | Back turning | Vc (m/min) | ||||

|

Finishing | TSF | T9215 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 150 – 400 |

| TSF | T9225 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 80- 300 | ||

| Medium to heavy cutting | TM | T9215 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 150 – 400 | |

| TM | T9225 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 80 – 300 | ||

|

Finishing | TSF | T9215 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 100 – 250 |

| TSF | AH8015 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 90 – 190 | ||

| Medium to heavy cutting | TM | T9215 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 100 – 250 | |

| TM | AH8015 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 90 – 190 | ||

|

Finishing | TSF | T9215 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 140 – 500 |

| Medium to heavy cutting | TM | T9215 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 140 – 500 | |

|

Finishing | TSF | AH8015 | 0.2 – 1.5 | 0.2 – 1.5 | 0.08 – 0.4 | 0.2 – 1.2 | 20 – 80 |

| Medium to heavy cutting | TM | AH8015 | 0.5 – 2.5 | 0.5 – 2.5 | 0.2 – 0.6 | 0.4 – 1.2 | 20 – 80 | |

Single-sided 3-corner insert

| ISO | Operation | Chipbreaker | Grade | Depth of cut: ap (mm) | Feed: f (mm/rev) | Cutting speed | ||

|---|---|---|---|---|---|---|---|---|

| Front turning | Back turning | Front turning | Back turning | Vc (m/min) | ||||

|

Medium to heavy cutting |

TM | T9215 | 0.5 – 4 | 0.5 – 2 | 0.2 – 0.6 | 0.4 – 2 | 150 – 400 |

|

Medium to heavy cutting |

TM | T9215 | 0.5 – 4 | 0.5 – 2 | 0.2 – 0.6 | 0.4 – 2 | 100 – 250 |

|

Medium to heavy cutting |

TM | T9215 | 0.5 – 4 | 0.5 – 2 | 0.2 – 0.6 | 0.4 – 2 | 140 – 500 |

For more information about this product, visit our online e-catalog or download the product report: