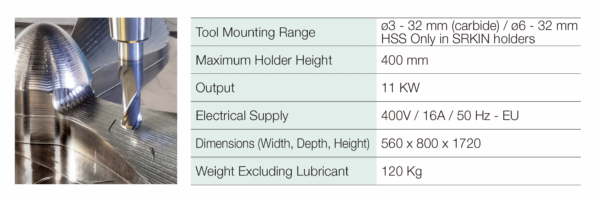

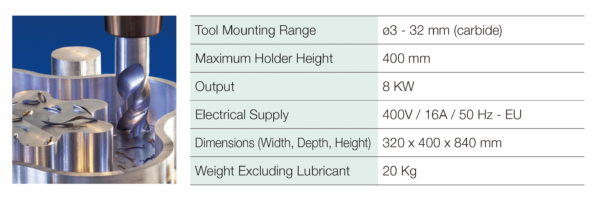

Iwaki, Japan – April, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its product lineup with the launch of TungShrink, a high-efficiency shrink-fit machine that automates the heating, cooling, and drying process in just 30 seconds, supporting tool diameters from ø3 to ø32 and available in both standard (AP type) and compact desktop (BS type) models.

Challenges and Trends

Conventional shrink fit machines have posed challenges in improving productivity due to the time-consuming cooling and drying process after tool shrink fitting. Furthermore, because all operations are performed manually, they tend to rely heavily on the operator’s skill and effort, which has led to growing demand for automation. Given these circumstances, the machining industry is seeking more efficient and user-friendly shrink fit machines, with reduced operation time and simplified procedures becoming major themes across the market.

Product Overview

TungShrink is a new shrink-fit machine that automates the shrink-fit process for cutting tools, significantly enhancing operability and work efficiency. It supports both carbide and HSS shanks and offers high versatility as a tooling system compatible with a wide range of holders.

Benefits and Features

Feature 1: High-Efficiency Machining Preparation with Automated Shrink Fit System

Automation of the heating and cooling processes significantly reduces operator workload

Rapid cooling and drying are completed in just 30 seconds, enabling smooth transition to the next process

Consistent heating and cooling control enhances the stability and repeatability of the shrink fit process

Feature 2: Easy Operation and High Usability

- Monitor-equipped control panel allows users to visually confirm operation procedures

- Barcode scanning function automatically recognizes tool information, preventing setting errors

- Ensures accurate shrink fitting regardless of operator skill level, enabling anyone to perform the process with ease

Feature 3: Flexible Lineup to Meet Diverse Needs

- Available in standard AP type and space-saving benchtop BS type models

- Compatible with a wide gripping diameter range from ø3 to ø32, accommodating various tool sizes

- Supports both carbide and HSS shanks, allowing use with different tool materials