Iwaki, Japan – March, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its Tung Hydro (High-Precision Type T Series), now available with an extended range of interfaces, including BT30/50, HSKA100, SK40/50, and CAT40/50. These additions enhance compatibility for precision machining applications worldwide, ensuring superior runout accuracy, high clamping force, and excellent vibration damping for improved tool life and machining stability.

Challenges and Trends

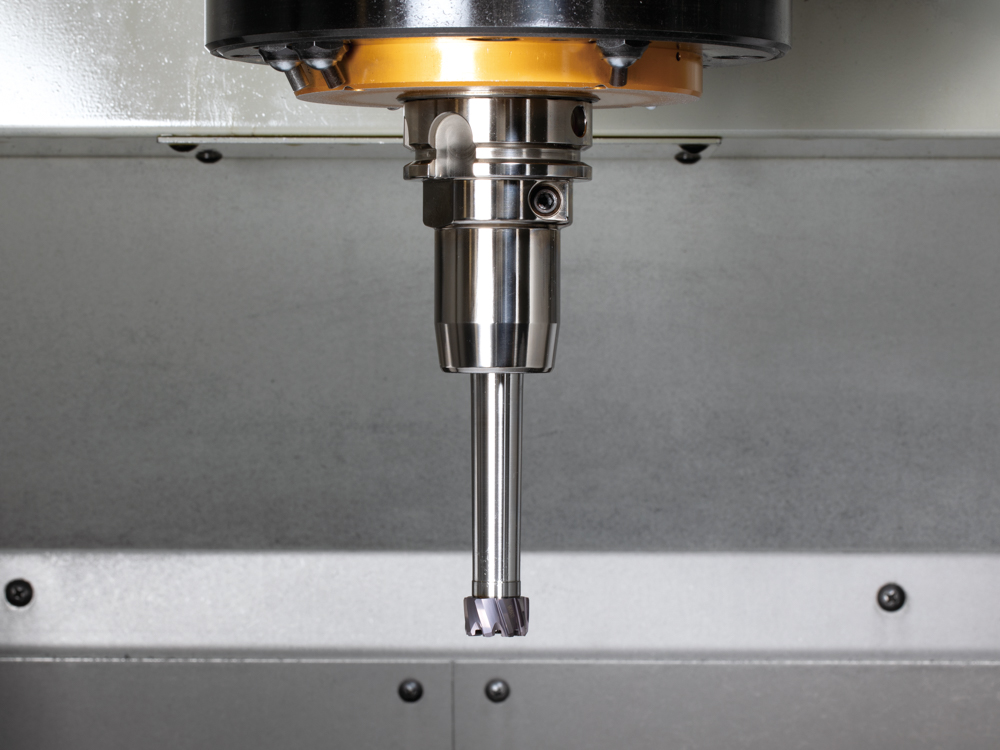

In many industries, including the automotive sector, deep hole machining and high-precision reaming of shaft components or hydraulic component are essential. When using rotating tools with long overhangs exceeding L/D = 8, ensuring machining accuracy becomes a significant challenge. Conventional collet chuck holders and side-lock holders not only require considerable time to achieve proper tool mounting accuracy but also struggle to maintain runout precision in long overhang applications. Therefore, there is a growing demand for tooling solutions that can achieve higher runout accuracy more easily.

Product Overview

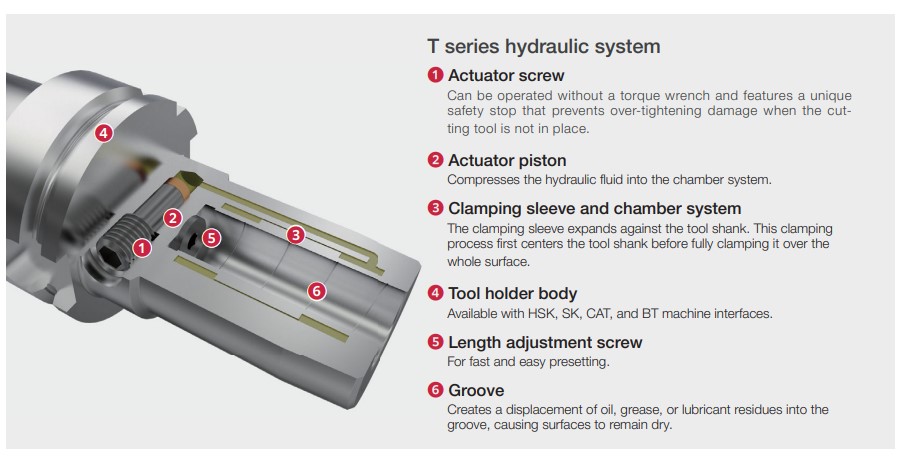

TUNGHYDRO series hydro chuck holder is Tungaloy’s latest hydraulic tool holder. It can be easily operated with a hex wrench and achieves high-precision clamping with a runout accuracy of 0.003 mm or less. With its high clamping force and rigidity, it minimizes vibration during machining, ensuring stable cutting performance. Compatible with HSK and JIS-BT standards, it is widely used in industries such as automotive, aerospace, and precision machinery. Even under high-load conditions, it delivers outstanding performance, contributing to improved machining accuracy and productivity.

Benefits and Features

Feature 1: High Runout Accuracy with Easy Operation

Achieves high-precision clamping with a runout accuracy of 0.003 mm or less by simply tightening the actuation screw with a hex wrench

Dead-stop mechanism ensures reliable and repeatable tightening

High-precision clamping contributes to improved machining accuracy and extended tool life

Feature 2: Stable Machining with High Clamping Force and Torque

Strong clamping force suppresses even the slightest tool movement

High clamping torque prevents tool slippage during heavy cutting and high-load machining

Stable clamping performance maintains machining accuracy and enhances surface finish quality

Feature 3: Outstanding Vibration Damping Mechanism

Unique hydraulic system suppresses vibrations and reduces chatter

Lowers the risk of tool breakage, improving machining reliability

Superior vibration damping effect enhances surface finish quality and extends tool life