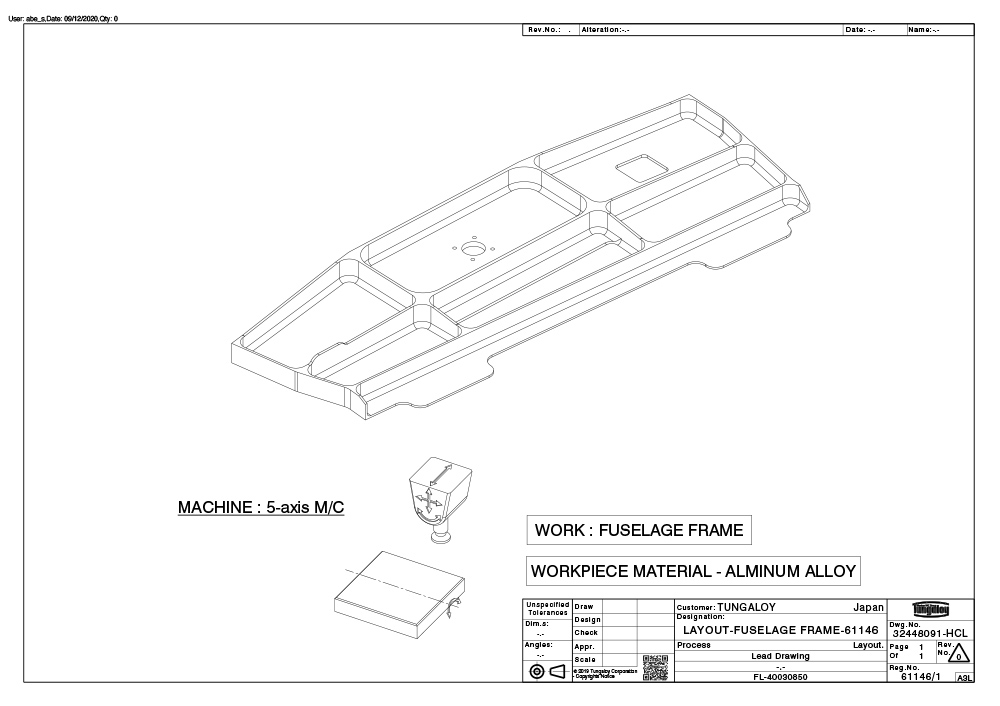

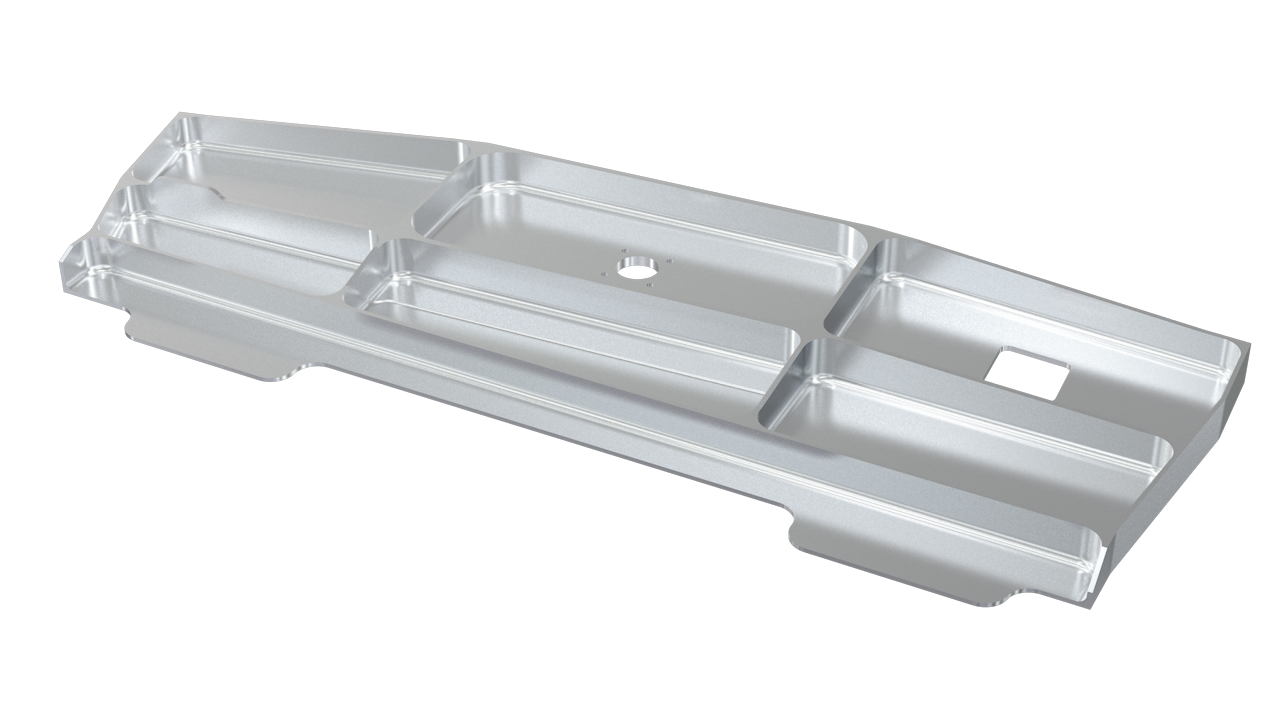

Aerospace – Fuselage Frame

Aluminum alloys are widely used in aircraft parts due to their lightness, reliability and economy.

In many cases, high-speed machining is applied to improve the efficiency of aluminum alloy machining. Tools with low cutting force are required as a means of preventing chattering in high-speed machining and chattering of thin-walled parts, which are often found in aircraft parts.

In addition, the frequency of use of new materials such as aluminum alloys, titanium alloys, and CFRP is increasing in pursuit of further mechanical properties. Tungaloy contributes to improving the productivity of aircraft parts by proposing tools and processing methods that employ our unique technology to handle aluminum alloys and other new materials.

Tooling concepts

- Improves productivity and prevents chattering on thin wall parts

- Application of low cutting force tools to achieve high speed and high D.O.C

- In order to maximize the performance of the 5-axis machine, apply multi-functional tools and machining methods such as ramping and contouring

Featured process

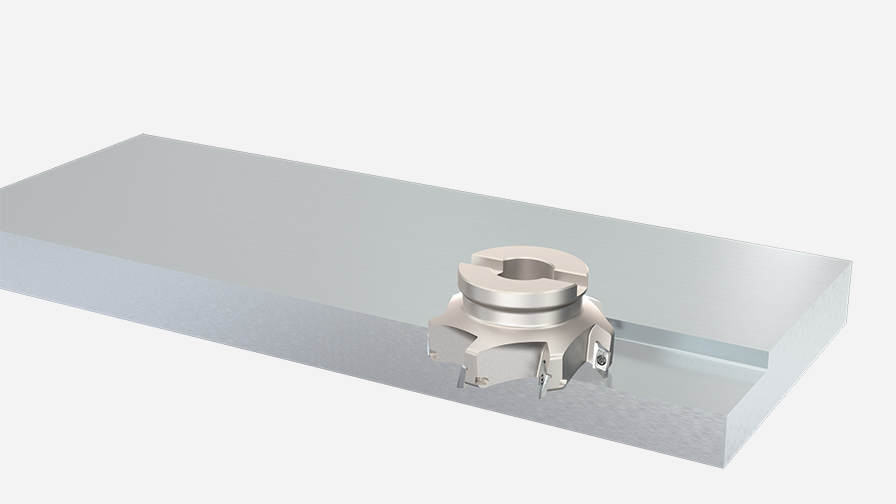

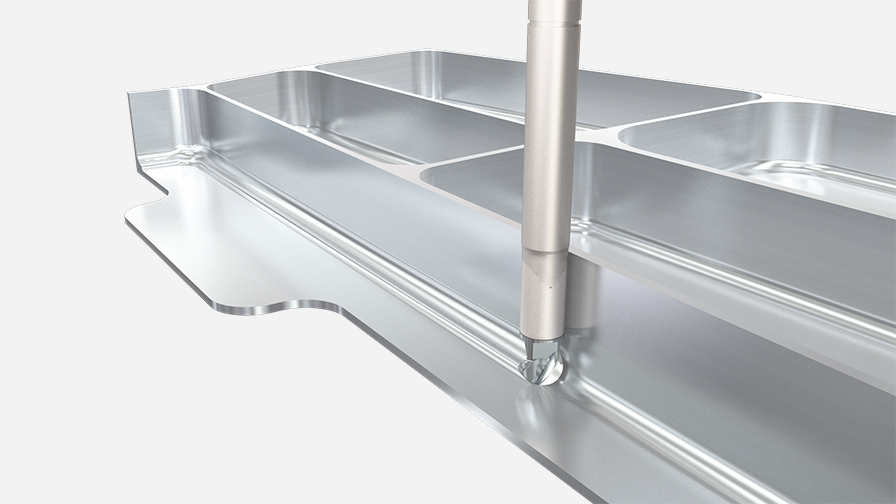

Process 1: Rough face milling

Benefits

- The V-shaped bottom geometry securely clamps the insert against centrifugal force. Enables stable, high-efficiency machining at extremely high cutting speeds

- Shoulder milling cutter with long cutting edge length for high depth of cut machining. Reduced machining time for rough milling process

- Cutting force is reduced by combining a sharp cutting edge and a large rake angle

- Polish treatment on the rake face of the insert reduces adhesion and achieves excellent machined surface quality

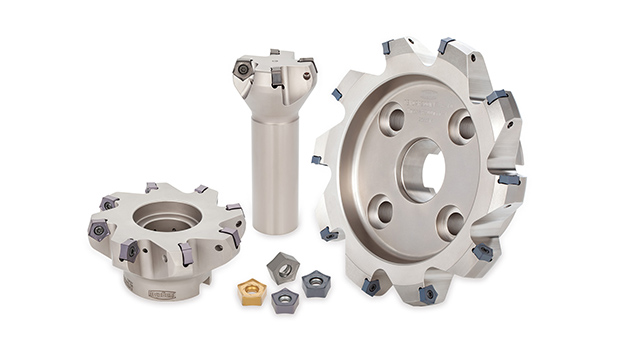

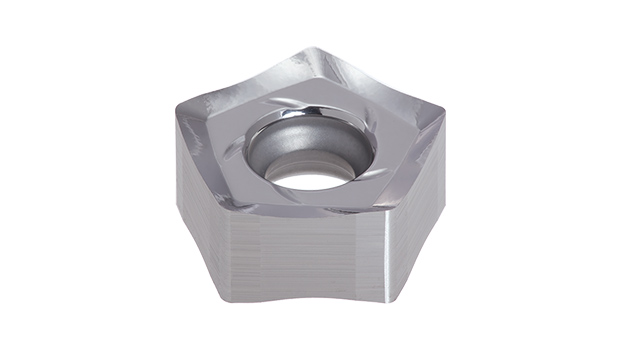

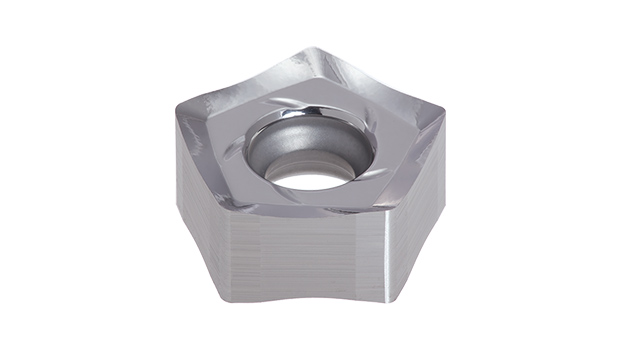

AJ chipbreaker

- High accuracy grinded insert

- Excellent machined surface quality by built in wiper edge

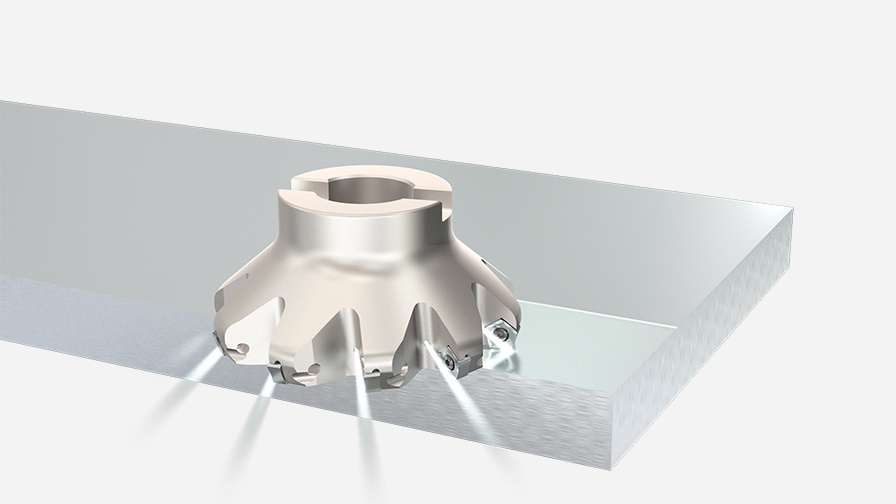

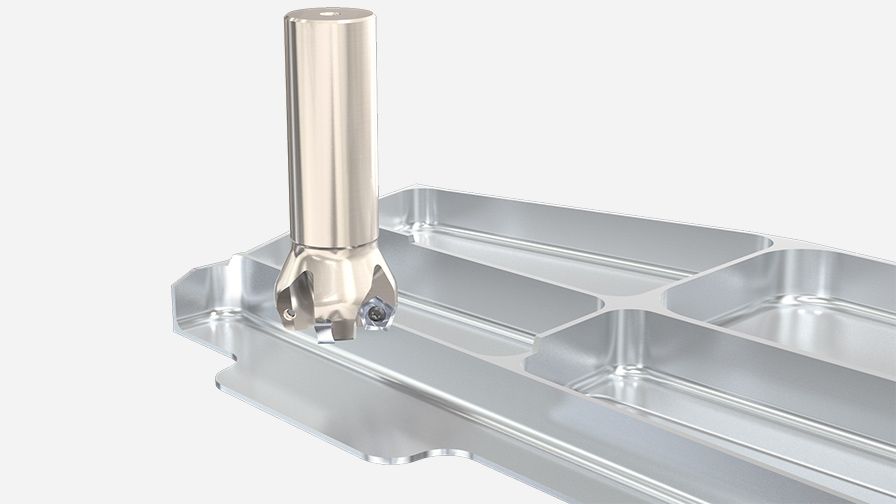

Process 2: Finish face milling

Benefits

- Polishing treatment on the rake face of the insert reduces adhesion and achieves excellent machined surface quality

- Cutting force is reduced by combining a sharp cutting edge and a large rake angle

- Highly rigid body design and high density for high productive machining

- Lineup of cutters with internal coolant channels. Wet machining contributes to excellent chip evacuation and improved machined surface quality

AJ chipbreaker

- AJ chipbreaker dedicated to aluminum machining and grade TH10 are available

- High economical insert with 10 edges

TERC-E3

- Roughing end-mill with 3 flutes and 38 deg helix

- KS15F grade keeps edge sharpness and prevents welding

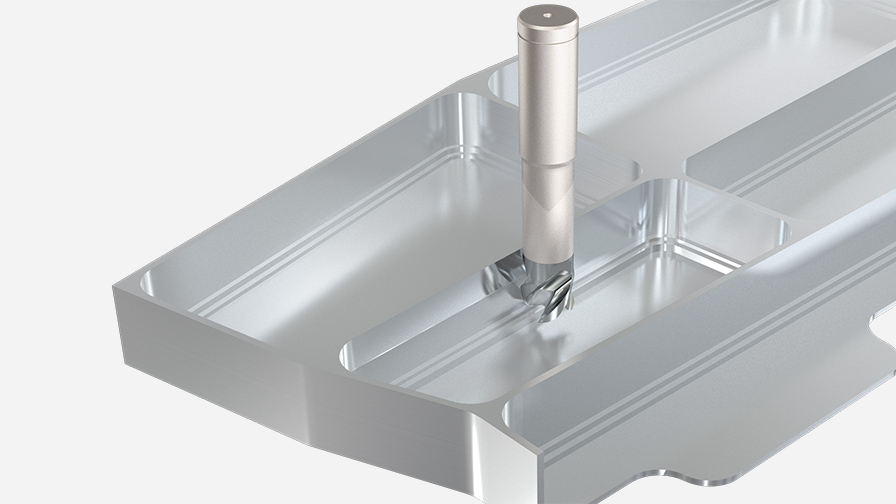

Process 4: Finish shoulder milling

Benefits

- Polishing treatment and a large rake angle prevents the occurrence of built-up edge that tends to occur when machining aluminum alloys. Maintains excellent machined surface quality

- A head can be combined with a carbide shank. Prevents chattering that tends to occur during long overhangs, and maintains high accuracy even in deep area machining

VEE-A03

- Cutting edge design specialized for aluminum machining

- Welding is prevented by polishing treatment

VBE-BGA

- Head exchange type tool supports easy management

- Excellent adhesion resistance due to polishing treatment

Process 6: Finish face milling

Benefits

- Polishing treatment on the rake face of the insert reduces adhesion and achieves excellent machined surface quality

- Cutting force is reduced by combining a sharp cutting edge and a large rake angle

- Highly rigid body design and high density for high productive machining

AJ chipbreaker

- AJ chipbreaker dedicated to aluminum machining and grade TH10 are available

- High economical insert with 10 edges