The best solution for steel and cast iron milling

Exact simulation analysis provides light weight cutter with low cutting

Applications & Features

Applications

Features

1. CBN grade inserts for high-speed cast iron machining

High CBN content grade composed of extremely dense medium CBN grains

Inserts & Grades

Inserts

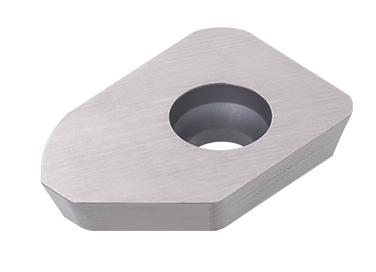

F2-SWGW

- Maximum depth of cut: 0.5 mm

WSGW

- Wiper edge

SW*T1304

- Maximum depth of cut: 10 mm

Grades

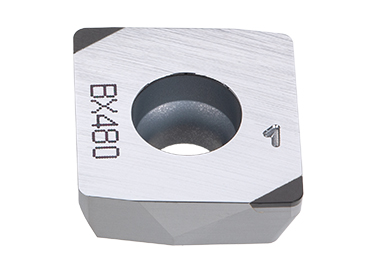

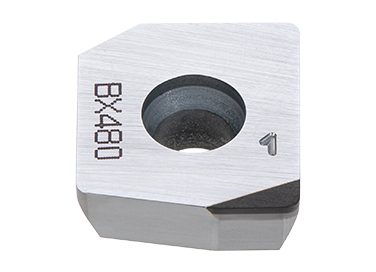

BX480

![]()

- Hardest CBN

- Ideal for ferrous sintered metal

- Suitable for high-speed face milling of cast iron

AH130

![]()

- High chipping and fracture resistance

- Designed for machining austenitic stainless steel under general cutting conditions

AH3135

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

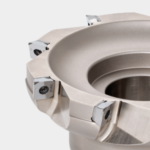

Cutter bodies

Shank Type

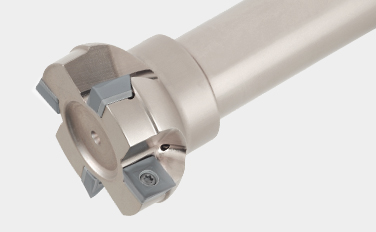

EPW13 (ø32 – ø80mm)

Square shoulder endmill, shank type, with screw clamp system

Practical examples

Example #1

| Part: | Cylinder block |

| Material: | FC250 / 250 |

| Cutter: | TPW13R125M38.1-08 (DCX = 125 mm, CICT = 8) |

| Insert: | 2-SWGW130508PDLSR x6, WSGW130508PDLSR x2 |

| Grade: | BX480 |

| Cutting conditions: | Vc = 800 (m/min) fz = 0.11 (mm/t) Vf = 1,760 (mm/min) ap = 0.2 (mm) ae = ~ 80 (mm) Application: Face milling Coolant: Dry Machine: Horizontal M/C, KM100 |

Example #2

| Part: | Cylinder block |

| Material: | FC250 / 250 |

| Cutter: | TPW13 cutter (customized, DCX = 250 mm, CICT = 12) |

| Insert: | 2-SWGW130508PDLSR x10, WSGW130508PDLSR x2 |

| Grade: | BX480 |

| Cutting conditions: | Vc = 1,178 ~ 1,257 (m/min) fz = 0.05 ~ 0.11 (mm/t) Vf = 900 ~ 1,980 (mm/min) ap = 0.2 (mm) ae = ~ 200 (mm) Application: Face milling Coolant: Dry Machine: Horizontal M/C, KM100 |

Example #3

| Part: | Hydraulic part |

| Material: | Chromium molybdenum steel (SCM415) |

| Cutter: | TPW13R080M25.4-04 (ø80, z=4) |

| Insert: | SWMT1304PDPR-MS |

| Grade: | AH140 |

| Cutting conditions: | Vc = 120 (m/min) fz = 0.18 (mm/t) Vf = 350 (mm/min) ap = 1.2 (mm) ae = ~ 50 (mm) Application: Face milling Coolant: Dry Machine: – |

Standard cutting conditions

TAW13, EAW13

| ISO | Workpiece materials |

Hardness | Priority | Grade | Cutting speed Vc(m/min) |

Roughing (Depth of cut ≥ 1.0 mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth:fz (mm/t) | |||||||||||

| MJ | ML | HJ | MS | Flat top | AJ | ||||||

|

Mild steel Low carbon steel |

< 180 HB | First choice | AH3225 (AH3135) |

100 – 270 | 0.05 – 0.3 | 0.05 – 0.25 | 0.2 – 0.6 | – | 0.05 – 0.3 | – |

| < 180 HB | Wear resistance | T3225 | 150 – 300 | 0.05 – 0.3 | – | 0.2 – 0.6 | – | 0.05 – 0.3 | – | ||

| < 180 HB | Surface quality | NS740 | 100 – 300 | 0.05 – 0.23 | – | – | – | 0.05 – 0.23 | – | ||

| Carbon steel Alloy steel |

< 300 HB | First choice | AH3225 (AH3135) |

100 – 230 | 0.05 – 0.25 | 0.05 – 0.2 | 0.2 – 0.5 | – | 0.05 – 0.25 | – | |

| < 300 HB | Wear resistance | T3225 | 150 – 280 | 0.05 – 0.25 | – | 0.2 – 0.5 | – | 0.05 – 0.25 | – | ||

| < 300 HB | Surface quality | NS740 | 100 – 230 | 0.05 – 0.2 | – | – | – | 0.05 – 0.2 | – | ||

| Die steel | < 30 HRC | First choice | AH3225 (AH3135) |

100 – 180 | 0.05 – 0.2 | 0.05 – 0.2 | 0.2 – 0.4 | – | 0.05 – 0.2 | – | |

| < 30 HRC | Wear resistance | T3225 | 100 – 180 | 0.05 – 0.2 | – | 0.2 – 0.4 | – | 0.05 – 0.2 | – | ||

|

Stainless steel | < 250 HB | First choice | AH3135 | 80 – 200 | 0.1 – 0.25 | 0.1 – 0.2 | 0.2 – 0.5 | 0.1 – 0.2 | – | – |

| < 250 HB | Wear resistance | T3225 | 150 – 250 | 0.1 – 0.25 | 0.1 – 0.2 | 0.2 – 0.5 | – | 0.1 – 0.25 | – | ||

|

Grey cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

150 – 250 | 0.05 – 0.25 | 0.05 – 0.2 | 0.2 – 0.6 | – | 0.05 – 0.25 | – |

| 150 – 250 HB | Wear resistance | T1215 | 180 – 300 | 0.05 – 0.25 | – | 0.2 – 0.6 | – | 0.05 – 0.25 | – | ||

| Ductile cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 180 | 0.05 – 0.25 | 0.05 – 0.2 | 0.2 – 0.6 | – | 0.05 – 0.25 | – | |

| 150 – 250 HB | Wear resistance | T1215 | 120 – 200 | 0.05 – 0.25 | – | 0.2 – 0.6 | – | 0.05 – 0.25 | – | ||

|

Aluminium alloys Si < 13% |

– | First choice | DS2005 KS05F |

300 – 1000 | – | – | – | – | – | 0.05 – 0.2 |

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | ||

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005 KS05F |

80 – 300 | – | – | – | – | – | 0.05 – 0.2 | |

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | ||

| Copper alloys | – | First choice | DS2005 KS05F |

200 – 500 | – | – | – | – | – | 0.05 – 0.2 | |

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | ||

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH130 | 30 – 60 | 0.1 – 0.25 | – | 0.2 – 0.5 | 0.1 – 0.2 | – | – |

| Heat-resistance alloys Inconel 718, etc. |

– 40 HRC | First choice | AH8015 (AH120) |

20 – 50 | 0.05 – 0.15 | – | 0.1 – 0.3 | – | – | – | |

|

Hardened steel SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 (AH120) |

45 – 70 | 0.08 – 0.15 | – | 0.1 – 0.3 | – | – | – |

– When using an aggressive depth of cut (for AP or AE), set the Vc and/or fz to the lower side of the value shown in the table.

– Dry cutting (or compressed air) is generally recommended. When excessive chip welding occurs on the cutting edge such as during stainless steel machining, use a water soluble cutting fluid and reduce Vc.

– When wet machining mild steel, carbon steel, or alloy steel, reduce the Vc and/or fz.

– Do not use TAW13 cutters for ramping, plunging, or drilling application as they are not designed for feeding in the Z axis direction.

| ISO | Workpiece materials |

Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Light cutting to finishing (Depth of cut < 1.0 mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth:fz (mm/t) | ||||||||||||

| MJ | ML | HJ | MS | Flat top | AJ | |||||||

|

Mild steel Low carbon steel |

< 180 HB | First choice | AH3225 (AH3135) |

100 – 270 | 0.05 – 0.25 | 0.05 – 0.2 | 0.2 – 0.6 | – | 0.05 – 0.25 | – | |

| < 180 HB | Wear resistance | T3225 | 150 – 300 | 0.05 – 0.25 | – | 0.2 – 0.6 | – | 0.05 – 0.25 | – | |||

| < 180 HB | Surface quality | NS740 | 100 – 300 | 0.05 – 0.2 | – | – | – | 0.05 – 0.23 | – | |||

| Carbon steel Alloy steel |

< 300 HB | First choice | AH3225 (AH3135) |

100 – 230 | 0.05 – 0.2 | 0.05 – 0.25 | 0.2 – 0.5 | – | 0.05 – 0.2 | – | ||

| < 300 HB | Wear resistance | T3225 | 150 – 280 | 0.05 – 0.2 | – | 0.2 – 0.5 | – | 0.05 – 0.2 | – | |||

| < 300 HB | Surface quality | NS740 | 100 – 230 | 0.05 – 0.18 | – | – | – | 0.05 – 0.18 | – | |||

| Die steel | < 30 HRC | First choice | AH3225 (AH3135) |

100 – 180 | 0.05 – 0.18 | 0.05 – 0.12 | 0.2 – 0.4 | – | 0.05 – 0.18 | – | ||

| < 30 HRC | Wear resistance | T3225 | 100 – 180 | 0.05 – 0.18 | – | 0.2 – 0.4 | – | 0.05 – 0.18 | – | |||

|

Stainless steel | < 250 HB | First choice | AH3135 | 80 – 200 | 0.1 – 0.2 | 0.1 – 0.18 | 0.2 – 0.5 | 0.1 – 0.18 | – | – | |

| < 250 HB | Wear resistance | T3225 | 150 – 250 | 0.1 – 0.2 | 0.1 – 0.18 | 0.2 – 0.5 | – | 0.1 – 0.2 | – | |||

|

Grey cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

150 – 250 | 0.1 – 0.2 | 0.05 – 0.18 | 0.2 – 0.6 | – | 0.1 – 0.2 | – | |

| 150 – 250 HB | Wear resistance | T1215 | 180 – 300 | 0.1 – 0.2 | – | 0.2 – 0.6 | – | 0.1 – 0.2 | – | |||

| Ductile cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 180 | 0.1 – 0.2 | 0.05 – 0.18 | 0.2 – 0.6 | – | 0.1 – 0.2 | – | ||

| 150 – 250 HB | Wear resistance | T1215 | 120 – 200 | 0.1 – 0.2 | – | 0.2 – 0.6 | – | 0.1 – 0.2 | – | |||

|

Aluminium alloys Si < 13% |

– | First choice | DS2005 KS05F |

300 – 1000 | – | – | – | – | – | 0.05 – 0.2 | |

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | |||

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005 KS05F |

80 – 300 | – | – | – | – | – | 0.05 – 0.2 | ||

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | |||

| Copper alloys | – | First choice | DS2005 KS05F |

200 – 500 | – | – | – | – | – | 0.05 – 0.2 | ||

| – | Wear resistance | DX140 | 200 – 800 | – | – | – | – | – | 0.05 – 0.2 | |||

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH130 | 30 – 60 | 0.1 – 0.21 | – | 0.2 – 0.5 | 0.1 – 0.2 | – | – | |

| Heat-resistance alloys Inconel 718, etc. |

– 40 HRC | First choice | AH8015 (AH120) |

20 – 50 | 0.05 – 0.15 | – | 0.1 – 0.3 | – | – | – | ||

|

Hardened steel |

SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 (AH120) |

45 – 70 | 0.08 – 0.15 | – | 0.1 – 0.3 | – | – | – |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 (AH120) |

40 – 65 | 0.05 – 0.1 | – | 0.05 – 0.14 | – | – | – | ||

– When using an aggressive depth of cut (for AP or AE), set the Vc and/or fz to the lower side of the value shown in the table.

– Dry cutting (or compressed air) is generally recommended. When excessive chip welding occurs on the cutting edge such as during stainless steel machining, use a water soluble cutting fluid and reduce Vc.

– When wet machining mild steel, carbon steel, or alloy steel, reduce the Vc and/or fz.

– Do not use TAW13 cutters for ramping, plunging, or drilling application as they are not designed for feeding in the Z axis direction.

TPW13, EPW13

| ISO | Workpiece materials |

Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Roughing (Depth of cut ≥ 1.0 mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth:fz (mm/t) | ||||||||||

| MJ | ML | MS | AJ | |||||||

|

Mild steel Low carbon steel |

< 180 HB | First choice | AH3225 (AH3135) |

100 – 270 | 0.05 – 0.25 | 0.05 – 0.2 | – | – | |

| < 180 HB | Wear resistance | T3225 | 150 – 300 | 0.05 – 0.25 | – | – | – | |||

| < 180 HB | Fracture resistance | AH3135 | 80 – 180 | 0.05 – 0.25 | – | 0.05 – 0.2 | – | |||

| < 180 HB | Surface finish | NS740 | 100 – 300 | 0.05 – 0.15 | – | – | – | |||

| Carbon steel Alloy steel |

< 300 HB | First choice | AH3225 (AH3135) |

100 – 230 | 0.05 – 0.2 | 0.05 – 0.15 | – | – | ||

| < 300 HB | Wear resistance | T3225 | 150 – 280 | 0.05 – 0.2 | – | – | – | |||

| < 300 HB | Fracture resistance | AH3135 | 80 – 150 | 0.05 – 0.2 | – | – | – | |||

| < 300 HB | Surface finish | NS740 | 100 – 230 | 0.05 – 0.15 | – | – | – | |||

| Die steel | < 30 HRC | First choice | AH3225 (AH3135) |

100 – 180 | 0.05 – 0.15 | 0.05 – 0.12 | – | – | ||

| < 30 HRC | Wear resistance | T3225 | 100 – 180 | 0.05 – 0.15 | – | – | – | |||

|

Stainless steel | < 50 HB | First choice | AH3135 | 80 – 200 | 0.05 – 0.2 | – | 0.05 – 0.18 | – | |

| < 50 HB | Wear resistance | T3225 | 150 – 250 | 0.05 – 0.2 | – | – | – | |||

|

Grey cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 250 | 0.05 – 0.2 | 0.05 – 0.15 | – | – | |

| 150 – 250 HB | Wear resistance | T1215 | 100 – 250 | 0.05 – 0.2 | – | – | – | |||

| 150 – 250 HB | Use when high efficiency milling is required |

BX480 | 800 – 1500 | 0.05 – 0.3 (F2-SWGW1305) |

– | – | – | |||

| Ductile cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 250 | 0.05 – 0.2 | 0.05 – 0.15 | – | – | ||

| 150 – 250 HB | Wear resistance | T1215 | 100 – 250 | 0.05 – 0.2 | – | – | – | |||

|

Aluminium alloys Si < 13% |

– | First choice | DS2005 KS05F |

300 – 1000 | – | – | – | 0.05 – 0.2 | |

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005 KS05F |

80 – 300 | – | – | – | 0.05 – 0.2 | ||

| Copper alloys | – | First choice | DS2005 KS05F |

200 – 500 | – | – | – | 0.05 – 0.2 | ||

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH130 | 30 – 60 | 0.1 – 0.25 | – | 0.1 – 0.2 | – | |

| Heat-resistance alloys Inconel 718, etc. |

– 40 HRC | First choice | AH8015 (AH120) |

20 – 50 | 0.05 – 0.15 | 0.05 – 0.1 | – | – | ||

|

Hardened steel |

SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 (AH120) |

45 – 70 | 0.08 – 0.15 | – | – | – |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 (AH120) |

40 – 65 | 0.06 – 0.1 | – | – | – | ||

– When using an aggressive depth of cut (for AP or AE), set the Vc and/or fz to the lower side of the value shown in the table.

– Dry cutting (or compressed air) is generally recommended. When excessive chip welding occurs on the cutting edge such as during stainless steel machining, use a water soluble cutting fluid and reduce Vc.

– When wet machining mild steel, carbon steel, or alloy steel, reduce the Vc and/or fz.

– Do not use TPW13 cutters for ramping, plunging, or drilling application as they are not designed for feeding in the Z axis direction.

| ISO | Workpiece materials |

Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Light cutting to fi nishing (Depth of cut < 1.0 mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth:fz (mm/t) | |||||||||

| MJ | ML | MS | AJ | ||||||

|

Mild steel Low carbon steel |

< 180 HB | First choice | AH3225 (AH3135) |

100 – 270 | 0.05 – 0.2 | 0.05 – 0.18 | – | – |

| < 180 HB | Wear resistance | T3225 | 150 – 300 | 0.05 – 0.2 | – | – | – | ||

| < 180 HB | Fracture resistance | AH3135 | 80 – 180 | 0.05 – 0.2 | – | 0.05 – 0.18 | – | ||

| < 180 HB | Surface finish | NS740 | 100 – 300 | 0.05 – 0.12 | – | – | – | ||

| Carbon steel Alloy steel |

< 300 HB | First choice | AH3225 (AH3135) |

100 – 230 | 0.05 – 0.18 | 0.05 – 0.12 | – | – | |

| < 300 HB | Wear resistance | T3225 | 150 – 280 | 0.05 – 0.18 | – | – | – | ||

| < 300 HB | Fracture resistance | AH3135 | 80 – 150 | 0.05 – 0.18 | – | – | – | ||

| < 300 HB | Surface finish | NS740 | 100 – 230 | 0.05 – 0.12 | – | – | – | ||

| Die steel | < 30 HRC | First choice | AH3225 (AH3135) |

100 – 180 | 0.05 – 0.12 | 0.05 – 0.1 | – | – | |

| < 30 HRC | Wear resistance | T3225 | 100 – 180 | 0.05 – 0.12 | – | – | – | ||

|

Stainless steel | < 50 HB | First choice | AH3135 | 80 – 200 | 0.05 – 0.18 | – | 0.05 – 0.15 | – |

| < 50 HB | Wear resistance | T3225 | 150 – 250 | 0.05 – 0.18 | – | – | – | ||

|

Grey cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 250 | 0.05 – 0.18 | 0.05 – 0.12 | – | – |

| 150 – 250 HB | Wear resistance | T1215 | 100 – 250 | 0.05 – 0.18 | – | – | – | ||

| Ductile cast iron | 150 – 250 HB | First choice | AH8015 (AH120) |

100 – 250 | 0.05 – 0.18 | 0.05 – 0.12 | – | – | |

| 150 – 250 HB | Wear resistance | T1215 | 100 – 250 | 0.05 – 0.18 | – | – | – | ||

|

Aluminium alloys Si < 13% |

– | First choice | DS2005 KS05F |

300 – 1000 | – | – | – | 0.05 – 0.2 |

| Aluminium alloys Si ≥ 13% |

– | First choice | DS2005 KS05F |

80 – 300 | – | – | – | 0.05 – 0.2 | |

| Copper alloys | – | First choice | DS2005 KS05F |

200 – 500 | – | – | – | 0.05 – 0.2 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | First choice | AH130 | 30 – 60 | 0.1 – 0.25 | – | 0.1 – 0.25 | – |

| Heat-resistance alloys Inconel 718, etc. |

– 40 HRC | First choice | AH8015 (AH120) |

20 – 50 | 0.05 – 0.15 | 0.05 – 0.1 | – | – | |

|

Hardened SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 (AH120) |

45 – 70 | 0.05 – 0.15 | – | – | – |

– When using an aggressive depth of cut (for AP or AE), set the Vc and/or fz to the lower side of the value shown in the table.

– Dry cutting (or compressed air) is generally recommended. When excessive chip welding occurs on the cutting edge such as during stainless steel machining, use a water soluble cutting fluid and reduce Vc.

– When wet machining mild steel, carbon steel, or alloy steel, reduce the Vc and/or fz.

– Do not use TPW13 cutters for ramping, plunging, or drilling application as they are not designed for feeding in the Z axis direction.

For more information about this product, visit our online e-catalog or download the product report: