CBN grade for hardened steel machining

Applicable for all types of hardened steel turning

Applications & Features

Applications

Features

1. Coated CBN grades applicable for all types of hardened steel turning

Grades

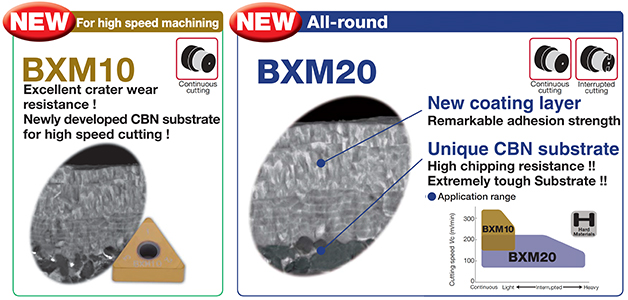

BXM10

![]()

- Coated CBN for excellent performance in high-speed continuous cutting of hardened steel

BXM20

![]()

- Coated CBN for machining hardened steel in a wide range of application area

Practical examples

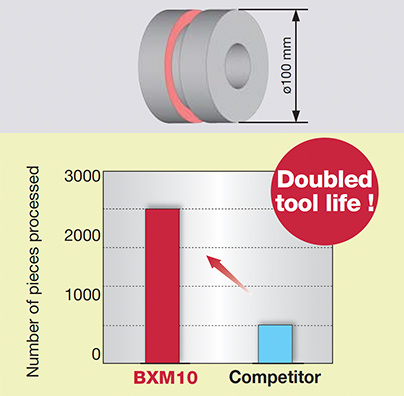

Example #1

Automotive Industry

| Part: | Automotive parts |

| Material: | SCr420, 20Cr4(H) (60 ~ 65HRC) |

| Insert: | 2QP-VNGA160408 |

| Grade: | BXM10 |

| Cutting conditions: | Vc = 150 (m/min) f = 0.05~0.07 (mm/rev) ap = 0.15 (mm) Application: Continuous cutting Coolant: Dry |

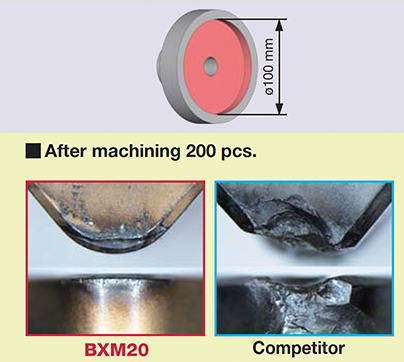

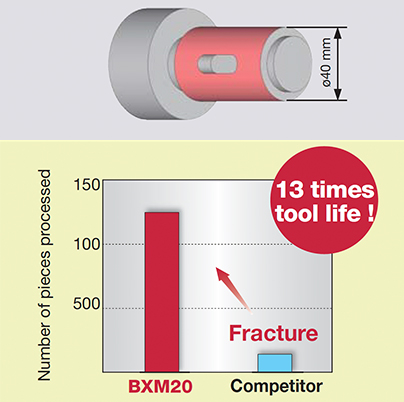

Example #2

Automotive Industry

| Part: | Automotive parts |

| Material: | SCr420, 20Cr4(H) |

| Insert: | 2QP-CNGA120408 |

| Grade: | BXM20 |

| Cutting conditions: | Vc = 90~120 (m/min) f = 0.12 (mm/rev) ap = 0.2~0.5 (mm) Application: Continuous cutting Coolant: Wet |

Example #3

Automotive Industry

| Part: | Automotive parts |

| Material: | SCr420, 20CrS4 (60 ~ 65HRC) |

| Insert: | 2QP-DNGA150408 |

| Grade: | BXM20 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.08 (mm/rev) ap = 0.1 (mm) Application: Continuous to interrupted cutting Coolant: Dry |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: