Coated CBN grade for hardened steel

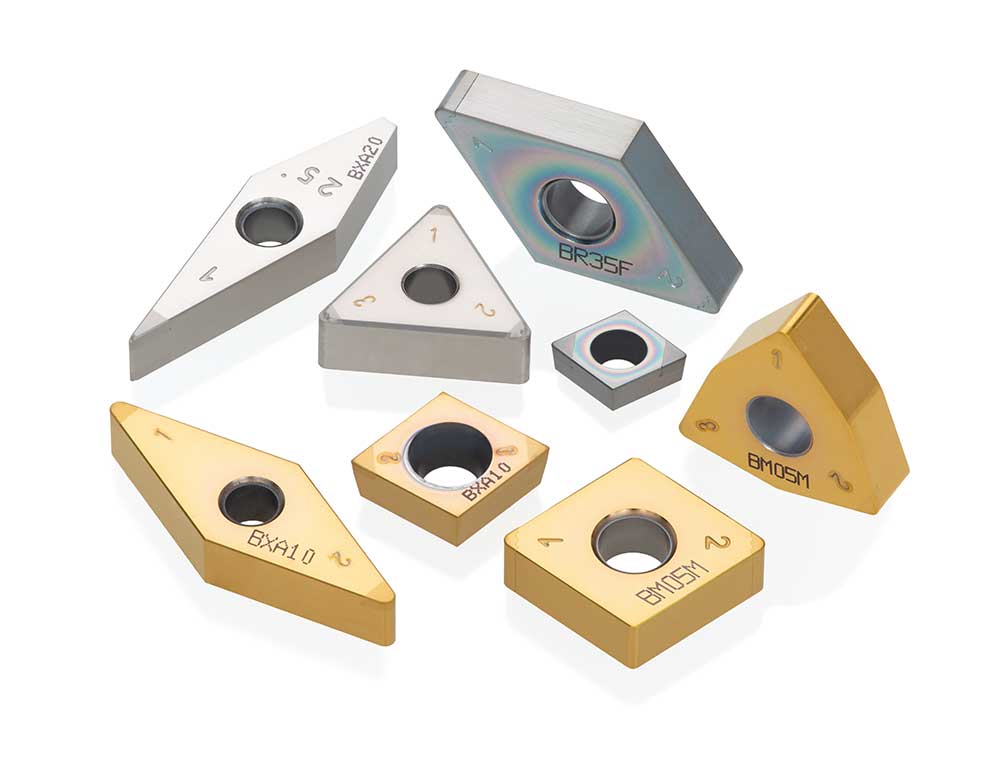

Coated CBN series for a wide range of hard part turning.

The most suitable grade can be selected for your application requirements.

Applications & Features

Applications

Features

1. Application area

2. Grade properties

3. WavyJoint

New brazing technology for increased machining efficiency

- A maximum depth of cut up to 0.8 mm.

Reduces the number of passes to increase productivity. - Innovative WavyJoint brazing technology

Prevents the CBN tips from debrazing, eliminating abrupt insert fractures during demanding dry machining, while securing stable and predictable hard turning operations.

4. Hardbreakder Series

- HS chipbreaker

Optimized chipbreaker design for excellent chip control during hard turning at aggressive conditions - HP chipbreaker

Designed for finish machining of hardened parts with close tolerances - HF and HM chipbreakers

Suited for hard turning applications requiring great D.O.C. such as carburized layer removal

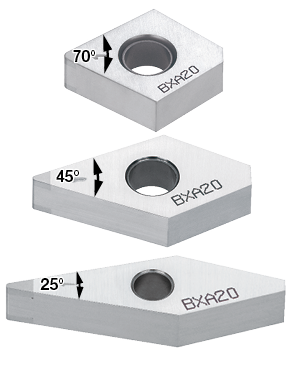

5. New CBN inserts for general turning

- GNGA insert with 70° corner angle

- FNGA insert with 45° corner angle

- Smaller corner angle provides the insert with greater clearance between the insert flank and workpiece surface, allowing better chip flow and evacuation.

- Enables greater D.O.C. in face turning applications in which the insert is pulled outward (fed away from the workpiece center).

- YNGA insert with 25° corner angle

- Allows undercutting, V grooving, and other applications that are not possible with traditional V inserts.

High versatility

- Existing ISO turning toolholder can be used for these inserts.

- For GNGA insert: Use the holder for CNxx1204 insert

- For FNGA insert: Use the holder for DNxx1504 insert

- For YNGA insert: Use the holder for VNxx1604 insert

- No offsets needed compared to ISO inserts, due to same geometry of cutting edge position.

- Double sided insert with 2 cutting edges.

6. MiniForce-Turn Double-sided positive insert with CBN tips

MiniForce-Turn now offers WavyJoint CBN inserts that provide additional strength and security in aggressive cutting conditions.

WXGQ0403… insert

7. CBN wiper insert series for extended application coverage

Available with HP chipbreaker and HS chipbreaker for effective chip control. Inserts with no chipbreaker are also available.

FW wiper eliminates chatter generation at slower feeds and offers good surface part quality.

MW wiper provides improved surface finishing at an increased feed rate.

Application areas

Grades

BXA10

![]()

- First choice for continuous to light interrupted cuts of hardened steel turning

- For cutting speed = 230 m/min or less

BXA20

![]()

- Versatile grade from continuous to heavy interrupted cuts

- For cutting speed = 180 m/min or less

BR35F

![]()

- First choice for heavy interrupted cuts

- For cutting speed = 150 m/min or less

Practical examples

Example #1

Automotive Industry

| Part: | Gear |

| Material: |

SCM420 / 18CrMo4 (62HRC) |

| Insert: |

2QP-CNGA120408 |

| Grade: | BXA10 |

| Cutting conditions: | Vc = 100 (m/min) f = 0.05 (mm/rev) ap = 0.15 (mm) Coolant: Dry |

Example #2

Automotive Industry

| Part: | CVT |

| Material: |

SCr420 / 20Cr4 (59HRC) |

| Insert: |

2QP-DNGA150412 |

| Grade: | BXA20 |

| Cutting conditions: | Vc = 170 (m/min) f = 0.3 (mm/rev) ap = 0.1 (mm) Coolant: Wet |

Example #3

Automotive Industry

| Part: | Gear |

| Material: |

SCM420 / 18CrMo4 (60HRC) |

| Insert: |

2QP-CNGA120412HC |

| Grade: |

BR35F |

| Cutting conditions: | Vc = 70 (m/min) f = 0.05 (mm/rev) ap = 0.15 (mm) Coolant: Dry |

Standard cutting conditions

| ISO | Grade | Workpiece condition | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|---|

|

BM05M | Continuous | 200 – 350 | 0.05 – 0.2 | 0.05 – 0.2 |

| BXA10 | Continuous | 100 – 230 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Light interrupted | 100 – 230 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BXA20 | Continuous | 60 – 180 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Interrupted | 60 – 180 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BR35F | Heavy interrupted | 50 – 150 | 0.05 – 0.3 | 0.05 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: