Solid carbide drills with 4 effective cutting edges for superior productivity

Four effective cutting edges for high drilling productivity

Applications & Features

Applications

Features

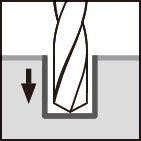

1. Optimized drill edge geometry allows smooth drill entry and stable drilling operations

2. Double feed of conventional two-flute drills

3. Four margins and a self-centering drill geometry enables high hole precision and quality

Drill bodies & Grades

Drill bodies

Main Grades

AH9130

![]()

![]()

![]()

![]()

- P15 – P35 / M25 – M35 / K10 – K25 / S15 – S30

- High wear resistance

- Designed for drilling various materials

Standard cutting conditions

| ISO | Workpiece material | Brinell hardness

(HB) |

Cutting speed

Vc (m/min) |

Feed: f (mm/rev) | |

|---|---|---|---|---|---|

| ø6 – ø9.9 | ø10 – ø16 | ||||

|

Grey cast irons FC300, etc. 250, etc. |

– 200 | 60 – 120 | 0.2 – 0.8 | 0.3 -1.0 |

| Ductile cast irons FCD450, etc. 450-10S, etc. |

– 300 | 60 – 120 | 0.2 – 0.8 | 0.3 -1.0 | |

- The cutting parameters shown in the table are a starting guideline.

Values should be varied depending on the power or rigidity of the machine.

Optimum conditions should be selected depending on the actual chip control or damage on edges. - When using the smaller diameter tools in each range, set the feed “f” to the lower values.

- When drilling with a depth deeper than L/D = 3, a pecking cycle or dwell operation should be considered depending on the actual chip control.

For more information about this product, visit our online e-catalog or download the product

report: