Applications & Features

Applications

Features

Deep face grooving of up to 10 mm DAXN and up to 9 mm groove depth is possible

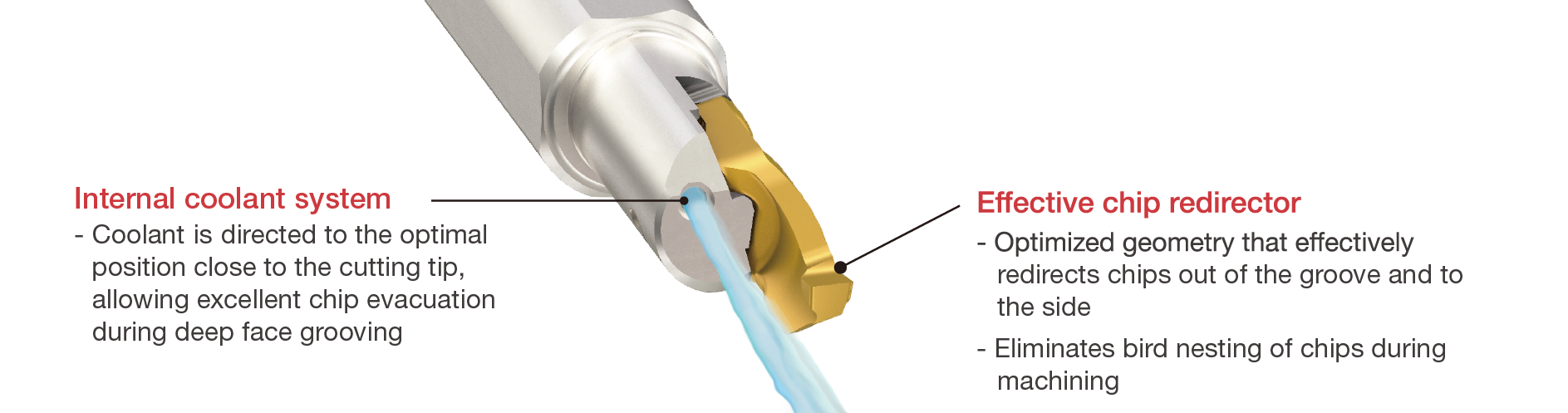

- Effectively removes chips out of the cutting area and eliminates bird nesting

- Extremely rigid insert clamping ensures tool stability during deep face grooving operations

- Sharp cutting edge, combined with SH7025, the latest PVD grade, provides long tool life and superior surface quality

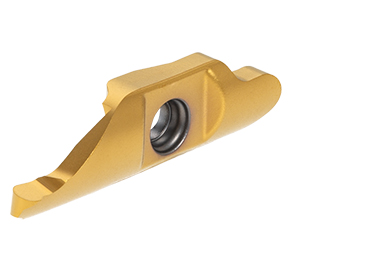

Superior chip evacuation

High clamping rigidity

SH7025 – the latest PVD insert grade for superior surface quality and process security

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

Superior process security

Chipping-resistant multi-layered TiAlN coating provides process security.

Inserts & Grades

Inserts

Grades

SH7025

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

Toolholders

Practical examples

Example #1

| Part: | Guide for linear motion bearing |

| Material: | SUS316 / X5CrNiMo17-12-2 |

| Toolholder: | A12G-MFR10-D100 |

| Insert: | MFGR10-200-020 |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 75 (m/min) f = 0.03 (mm/rev) CW = 2 (mm) CDX = 5 (mm) Application: Deep face grooving Coolant: Wet |

Example #2

| Part: | Spool pin |

| Material: | SCM415 |

| Toolholder: | A12G-MFR10-D100 |

| Insert: | MFGR10-200-020 |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 50 (m/min) f = 0.02 (mm/rev) CW = 2 (mm) CDX = 2.5 (mm) Application: Deep face grooving Coolant: Wet |

Standard cutting conditions

Grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Low carbon steels S15C, etc. C15E4, etc. |

SH7025 | 30 – 120 | 0.01 – 0.07 | |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMoS4, etc. |

SH7025 | 30 – 120 | 0.01 – 0.07 | |

| Prehardened steel NAK80, PX5, etc. |

SH7025 | 30 – 120 | 0.01 – 0.07 | |

| Stainless steels SUS304, etc. X5CrNi18-9, etc. |

SH7025 | 30 – 120 | 0.01 – 0.07 |

For more information about this product, visit our online e-catalog or download the product report: