Iwaki, May 2024— Tungaloy has expanded its TetraForce-Cut parting and grooving tool series with AH7025 grade inserts.

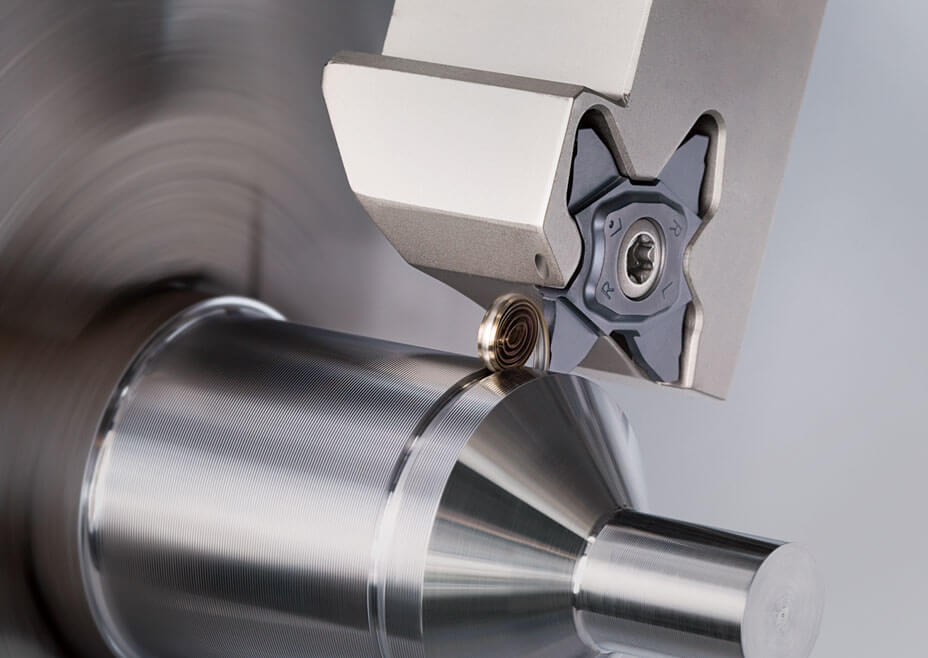

TetraForce-Cut incorporates economical four-edged parting and grooving inserts. The insert is clamped tangentially on a side of the tool holder, positioned against three peripheral contact surfaces to ensure indexing accuracy and tool reliability in various grooving and parting applications. The insert geometries are available in three styles: TCS features a pressed-in chipbreaker optimized for versatile parting and grooving applications; TCM geometry provides the insert edge with sharpness and robustness, enabling increased machining efficiency; and TCL incorporates a sharp cutting edge for reduced cutting forces.

The new inserts are coated in AH7025. This nano-multilayer PVD hard coating, with high aluminum content, combined with a fracture-resistant carbide substrate, provides the inserts with hardness and adhesion for better process security and longer tool life during grooving and parting operations. Since the coating is prepared in a multilayer structure, microcracks tend to branch and deflect at the interface between two alternating layers of different materials. This prevents cutting edge damage, dramatically improving the cracking resistance. With a strong coating substrate adhesion, the coating also provides optimized edge integrity.

With the release of the 75 new AH7025 grade inserts, the TetraForce-Cut will offer even longer insert tool life and ensure stable grooving and parting, contributing to improved productivity and machining efficiency for customers in all industries.

Product information

No. 416S9-G (Metric)

TetraForce-Cut