Iwaki, November 2020 — Tungaloy has expanded its DoTwist-Ball line of profile, high feed milling cutters to include new geometry, grades, and cutter bodies that will improve productivity in stainless steel applications.

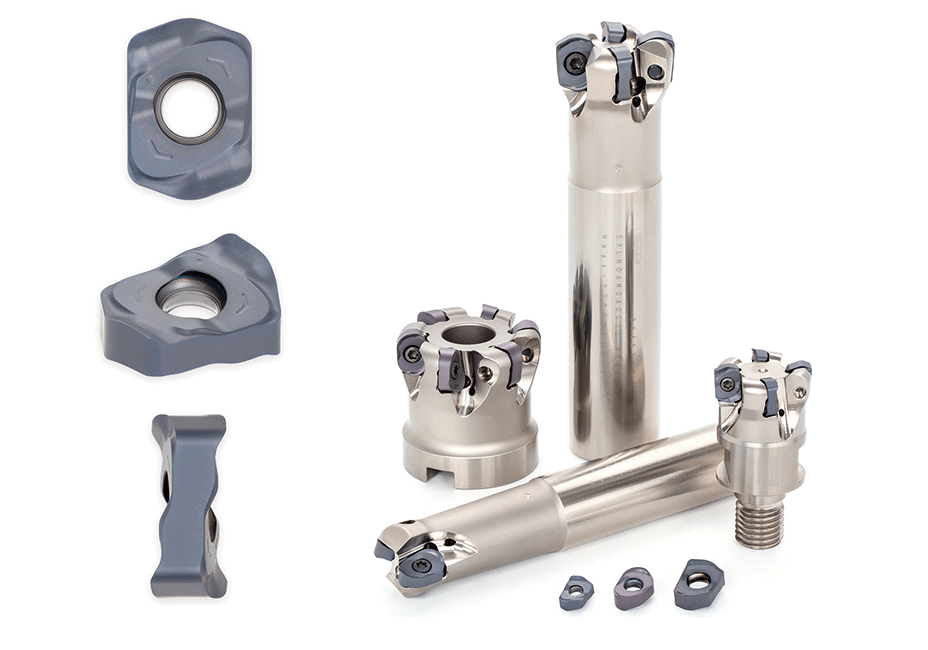

DoTwist-Ball allows two different shapes of inserts to fit the same cutter body, each dedicated for 3D profiling and high feed applications. The insert is designed in a helically twisted structure, which fits the seat constructed in a matching helical profile. This design provides secure insert positioning and retention during demanding operations.

The radius inserts are double-sided with a unique oval shape and four true economical cutting edges. The high feed inserts, also in a double-sided four-edged geometry, incorporate a large rake and inclination angle that form a sharp cutting edge. This promotes light cutting and good chip evacuation, eliminating chip re-cutting during the machining of deep pockets and cavities.

New LNMX-HL geometry further enhances the high feed milling capability of DoTwist-Ball. Incorporating a larger positive rake angle and sharper and stronger cutting edges to surpass the existing features of -HJ geometry, LNMX-HL provides high performance in stainless steel machining, while reducing cutting forces and chatter tendency.

The latest grade additions include PVD grades AH3225 for steel and stainless steel and AH8015 for exotic materials. The two grades provide long tool life in both profiling and high feed machining.

New modular heads and long shank bodies have been added to enhance the cutter body lineup to accommodate the smaller LNMX04 inserts, expanding DoTwist-Ball capability in long reach applications.

Product information

No. 507S1-G