Understanding Chatter in End Milling

End milling is widely used for manufacturing precision components, but chatter during machining can cause irregular surface patterns, reducing dimensional accuracy and overall quality. This article explores practical techniques to suppress chatter and improve machining stability.

Identifying Chatter in Machining

Do you notice irregular patterns on your machined surfaces? These are signs of chatter, a vibration that negatively impacts surface finish and accuracy.

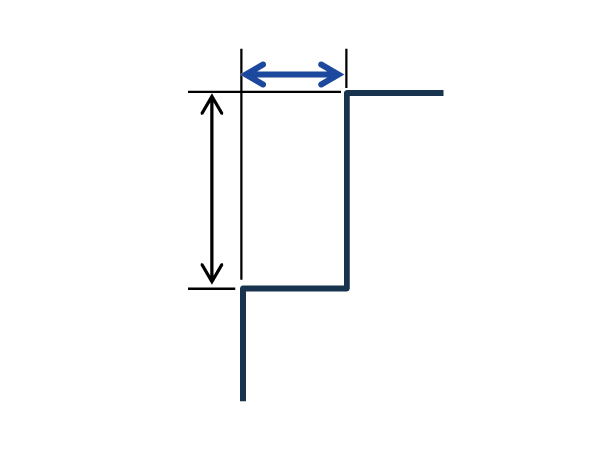

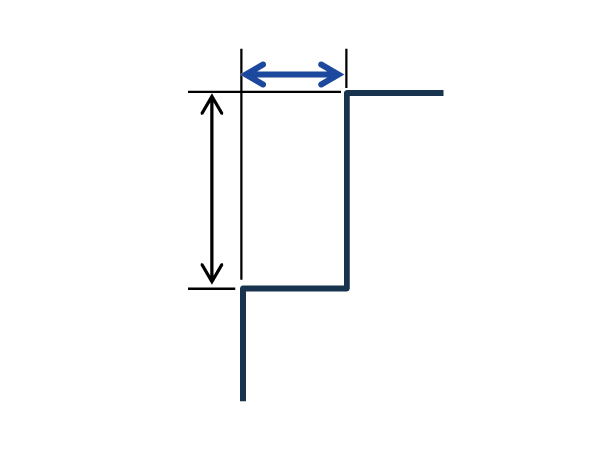

What Causes Chatter?

The primary cause of chatter is tool deflection. As shown in the diagram, when force is applied from one side, the tool deflects in the opposite direction, generating vibrations that result in chatter.

One effective way to reduce tool chatter and deflection is by using roughing end mills with low cutting resistance.

Roughing vs. Square End Mills: Pros and Cons

While roughing end mills reduce chatter due to their serrated cutting edges, they often result in a rougher surface finish. Square end mills, on the other hand, provide a smoother finish but are more prone to chatter.

| Roughing EndMill | Square EndMill | |

| cutting edges |

serrated cutting edges

|

Straight cutting edges

|

| Chattering | Hard to chatter | Easy to chatter |

| Application | Roughing | Finishing |

| surface |

Rough(Ra 1.5)

|

Good(Ra 0.3)

|

Combination End Mills: The Best of Both Worlds

To overcome the drawbacks of using separate roughing and finishing tools, combination end mills integrate both cutting edge designs, reducing chatter while achieving a smooth surface finish.

| Roughing EndMill | Combination EndMill | Square EndMill | |

| cutting edges |

serrated cutting edges

|

serrated cutting edges+Straight cutting edges

|

Straight cutting edges

|

| Chattering | Hard to chatter | Hard to chatter | Easy to chatter |

| Application | Roughing | Roughing+Finishing | Finishing |

| Depth of cut |

High(ae=0.3D)

|

High(ae=0.3D)

|

Low(ae=0.1D)

|

| Surface |

Rough

(Ra 1.5)

|

Good

(Ra 0.3)

|

Good

(Ra 0.3)

|

| Cost |

High

|

High

|

Middle

|

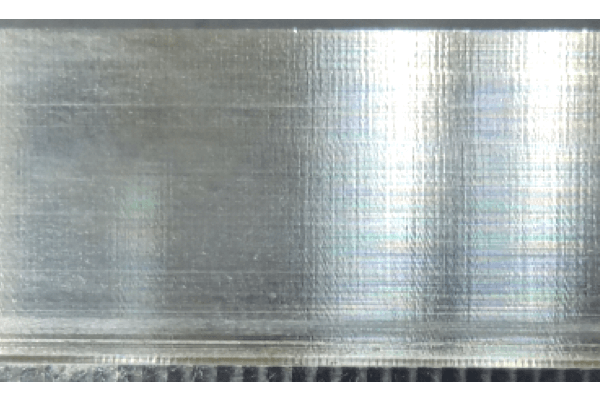

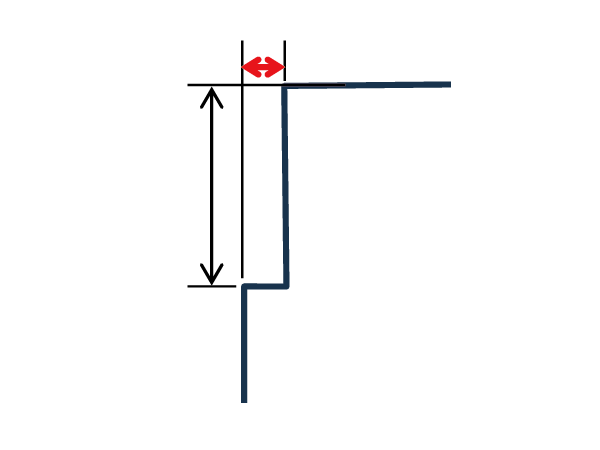

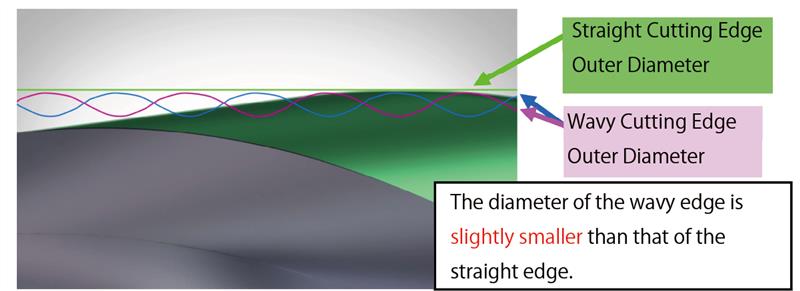

How a Square End Mill Can Achieve a Smooth Surface Without Chatter

The key lies in tool design. In combination end mills, the straight cutting edges are slightly offset, ensuring a clean surface finish while maintaining stability.

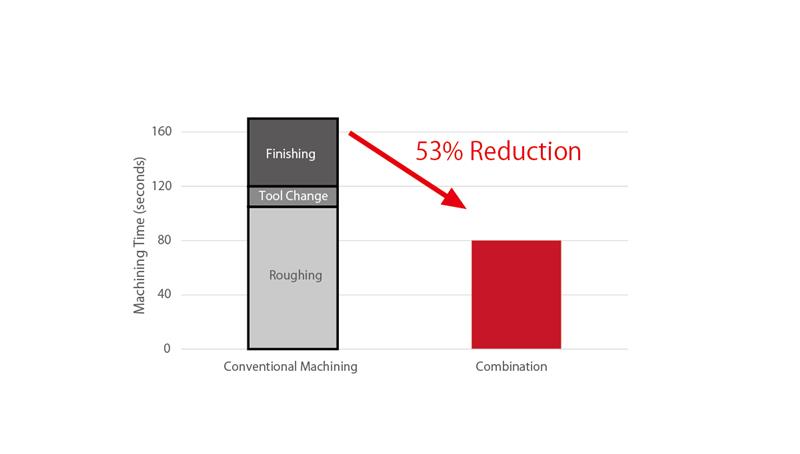

Practical Example: Improved Efficiency with a Combination End Mill

Traditionally, roughing and finishing require separate tools. However, by switching to a combination end mill, machining time was reduced by 53% while maintaining excellent surface quality.

Workpiece material: Titanium alloy, Tool diameter: 16mm, ap= 24mm

|

Combination: Vc= 45m/min fz= 0.03mm/t ae= 6mm Conventional machining: Roughing (4z): Vc= 35m/min, fz= 0.03mm/t, ae= 5.7mm Finishing (6z): Vc= 45m/min, fz= 0.03mm/t, ae= 0.3mm |

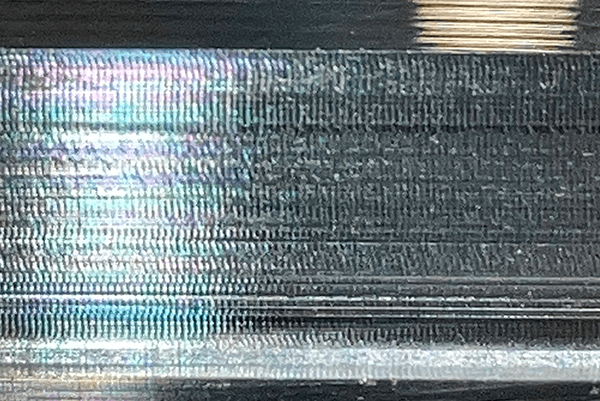

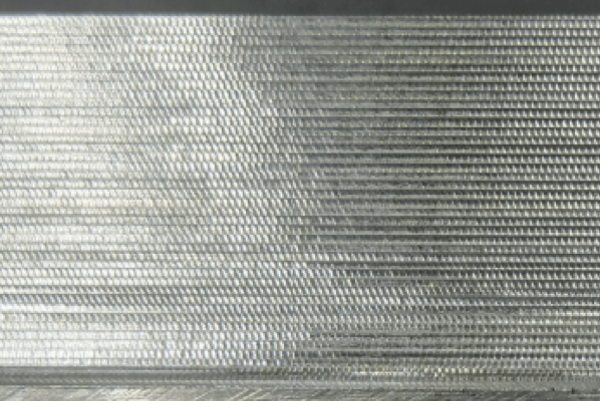

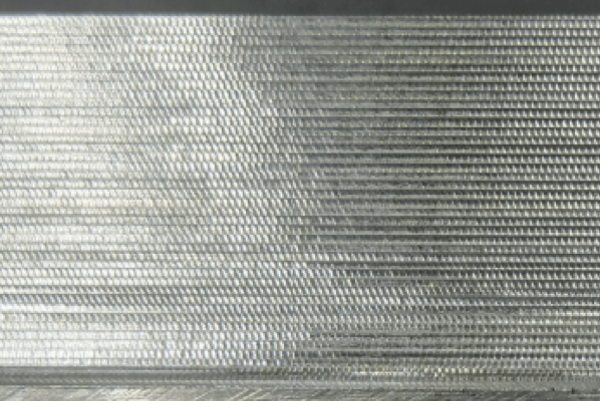

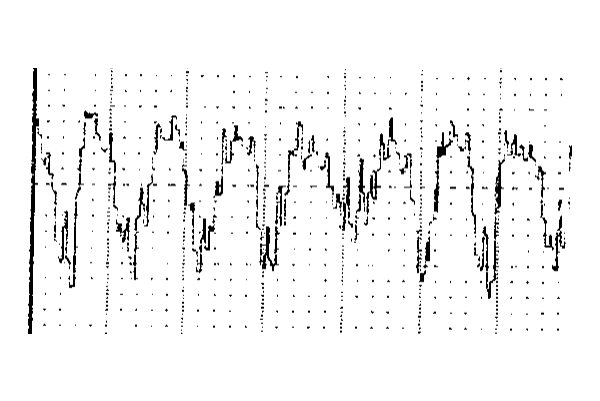

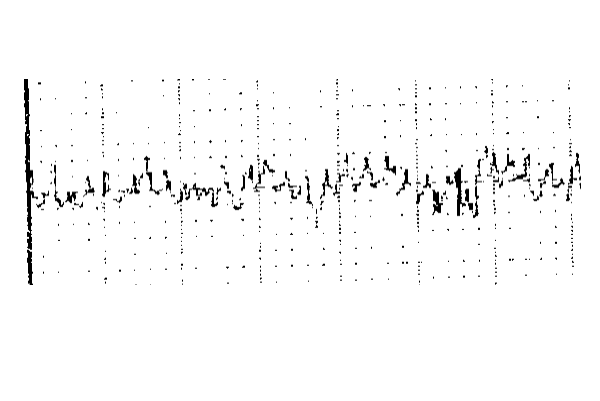

When tested against a competitor’s square end mill, the combination end mill provided significantly better surface roughness (Ra, Rz) due to reduced chatter.

| Square EndMill | Combination EndMill | |

| Surface |

Chattering

|

Good

|

| Surface roughness |

Ra 1.394 μm

Rz 5.323 μm

|

Ra 0.349 μm

Rz 1.947 μm

|

Material to be cut: S50C

Tool diameter: 6mm

ap= 6mm, Vc= 130m/min, fz= 0.03mm/t, ae= 0.3mm

User Feedback

Test users reported key benefits:

- Reduced Tool Changes: “Previously, we used separate roughing and finishing tools. Now, with a combination end mill, machining time has significantly decreased.”

- Extended Tool Life: “Other square or radius end mills developed chatter and burrs after machining a few dozen parts, requiring frequent replacements. This tool maintains stability and extends tool life.”

- Smooth Performance: “The test ran smoothly without major concerns. I believe the tool life will exceed expectations.”

Case Study: FinishMeister in Real Applications

Conventional end mills faced severe chatter during roughing, limiting productivity. The FinishMeister end mill, with its unique cutting edge design, successfully overcame this challenge by: ✅ Allowing 6× deeper cuts

✅ Increasing feed rates by 1.5×

✅ Doubling the number of cutting edges

As a result, productivity improved by 14× compared to conventional methods.

If You Struggle with Chatter, Try a Combination End Mill

Switching to a combination end mill can integrate roughing and finishing into a single tool, improving efficiency while reducing costs.

Tungaloy offers both solid-type and head-exchangeable versions—check out the links below for more details!