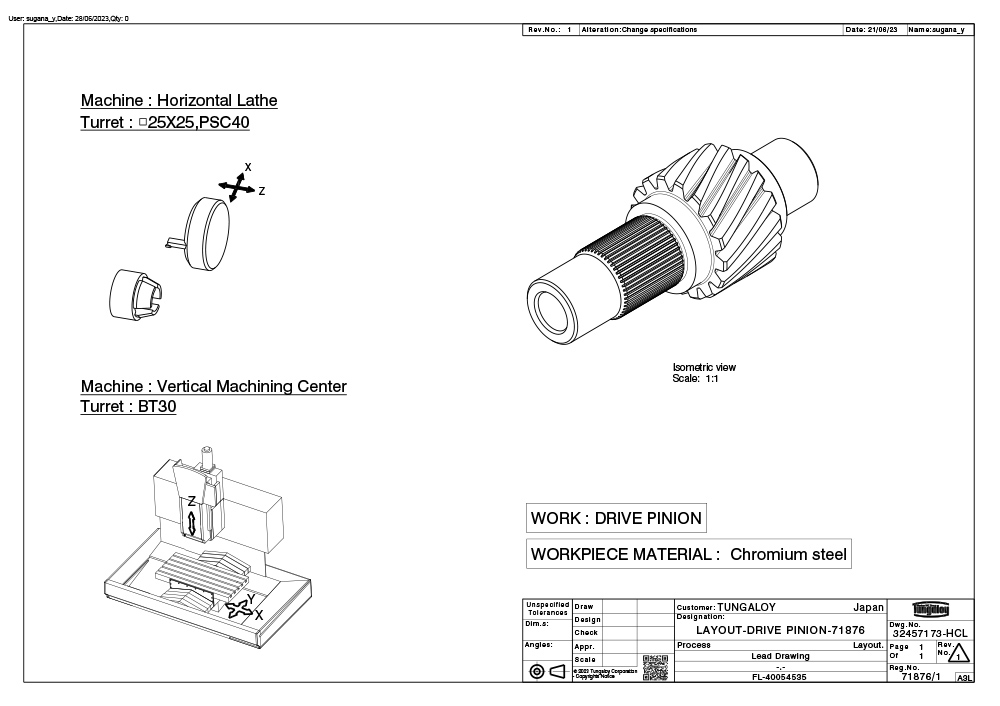

Automotive – Drive Pinion

The automotive drive pinion is a component that receives power from the engine to drive the wheels, controls speed and torque, and supports the vehicle’s power transmission and drivability.

As part of the vehicle’s powertrain, it plays a crucial role in providing appropriate driving characteristics and is a core element of the automobile’s power transmission system.

Due to the use of low carbon steel (such as SCr420, SCM415) in automotive drive pinions, which is challenging to manage in terms of chip disposal, there are many cases where chip disposal presents issues.

Post-hardening machining is also necessary, making the use of efficient and economical CBN inserts an important point.

Tungaloy, with its proprietary technology, offers comprehensive solutions that lead to the resolution of shaft machining challenges, such as “deep hole machining,” “chip disposal improvement,” and “efficient use of CBN inserts.”

Tooling concepts

- Utilizing tools capable of one-shot machining eliminates the need for a pilot hole, even in deep hole machining, resulting in significantly reduced machining time.

- Achieve high-efficiency machining through high-feed finish milling with AddMultiTurn technology.

- Minimize machine downtime with TungCap tooling for enhanced performance and reliability.

- Improve machining efficiency and lower production costs by applying hard turning in post-hardening processes, eliminating the need for grinding.

Featured process

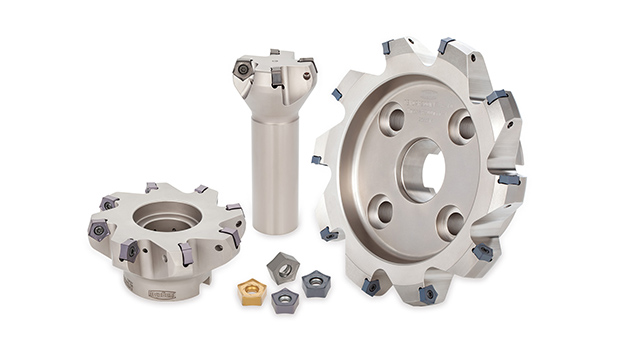

Process 1: Face milling

Benefits

- Operations on weakly clamped forged pieces.

- Cutter with a 70° cutting angle:

- Ideal angle for a balance between main and back forces.

- Provides stability and reliable control, especially with unstable clamping forces on forged materials.

- Sharp cutting edge and large rake angle reduces cutting resistance.

- High body rigidity design and multiple flutes for compatibility.

- Achieves high-efficiency machining.

- The AH3225 grade achieves an extraordinary long life by balancing wear resistance and fracture resistance at a high level.

- Economical with 10 cutting edges.

Process 2: Drilling

Benefits

- Quick centering shape and double margins stabilize the head behavior, achieving excellent surface roughness and straightness.

- Rapid head changes contribute significantly to reducing machine downtime.

- Two twisted coolant holes ensure superior cooling of the cutting edge and efficient chip evacuation.

DMC head

- Exceptional biting performance due to a unique cutting edge shape.

- Coating grades are optimized specifically for drilling operations, and ensure remarkable tool life.

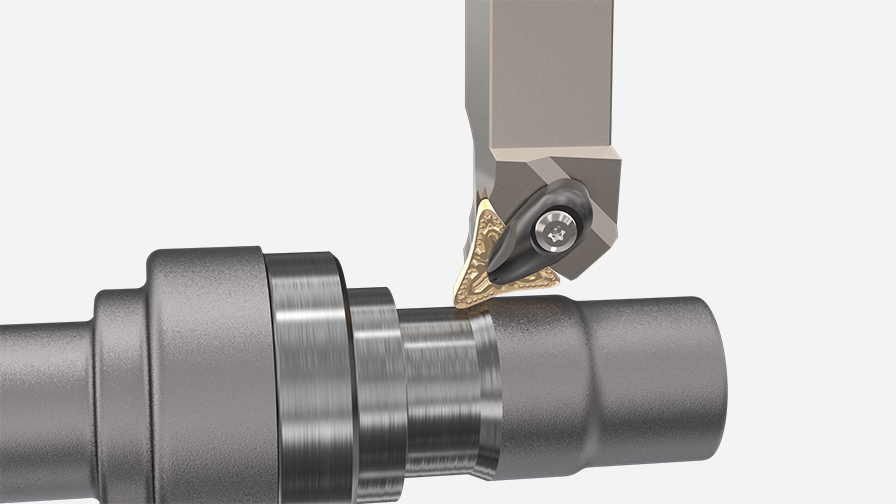

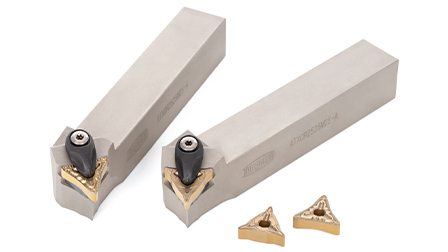

Process 3: Rough external turning

Benefits

- The high-feed edge geometry with back turning enables highly efficient machining, surpassing conventional ISO tools by approximately 200% in turning operations.

- The back turning effectively minimizes the occurrence of ringing shape burr, a common issue in stepped shaft machining.

- The Y-PRISM insert clamping system, known for its uniqueness and robustness, ensures excellent clamping rigidity. This feature allows for stable multi-directional machining and facilitates high-efficiency processing.

6C-TOMG-TM

- Economical with a double-sided 6-corner specification.

- An 80° corner angle type applicable from medium to rough cutting operations.

- The T9215 grade ensures exceptional wear and fracture resistance in steel turning operations, providing outstanding performance.

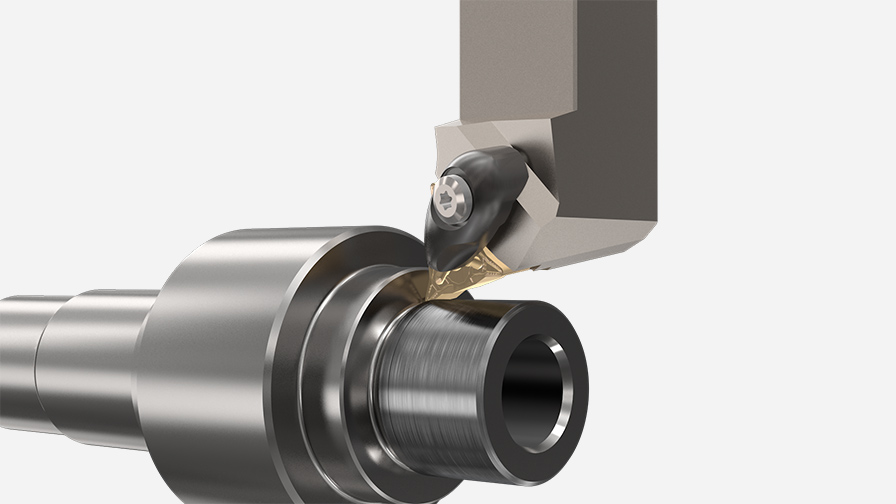

Process 4: Finish external turning

Benefits

- The high-feed edge geometry with back turning enables highly efficient machining, surpassing conventional ISO tools by approximately 200% in turning operations.

- The back turning effectively minimizes the occurrence of ringing shape burr, a common issue in stepped shaft machining.

- The Y-PRISM insert clamping system, known for its uniqueness and robustness, ensures excellent clamping rigidity. This feature allows for stable multi-directional machining and facilitates high-efficiency processing.

6V-TOMG-TSF

- Economical with a double-sided 6-corner specification.

- A 35° corner angle type optimized for finishing operations.

- The T9215 grade ensures exceptional wear and fracture resistance in steel turning operations, providing outstanding performance.

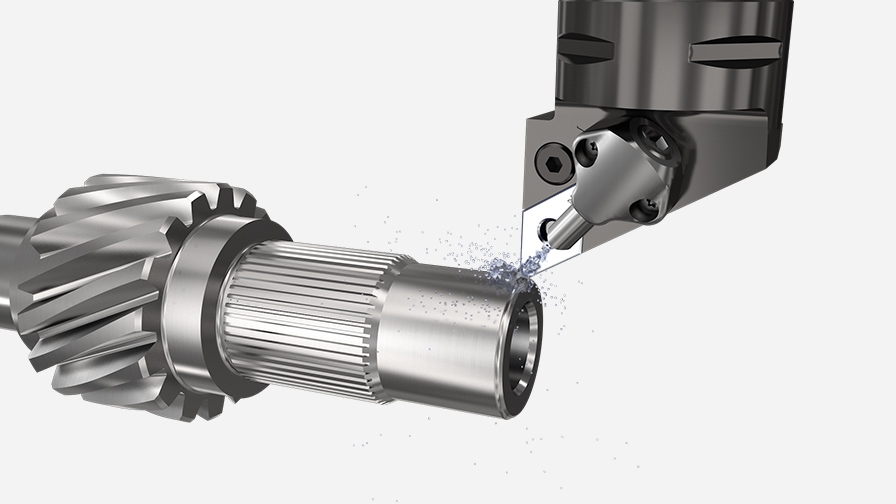

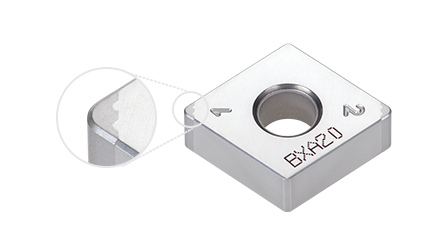

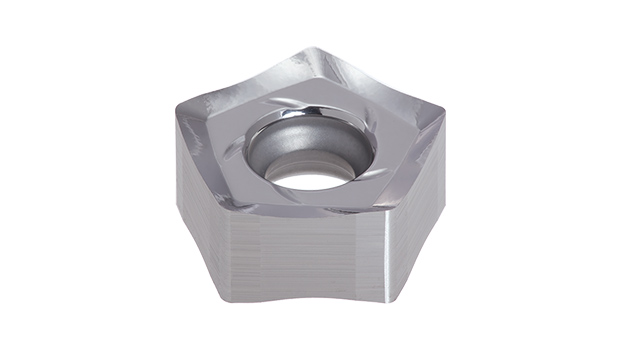

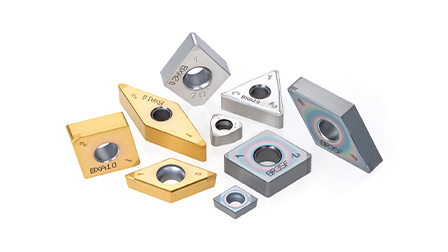

Process 5: Finish external turning (Hard turning)

Benefits

- The WavyJoint insert, with its large brazing contact area, effectively dissipates heat generated at the cutting edge during cutting, reducing edge temperature and suppressing crater wear.

- The TungTurn-Jet holder further reduces the edge temperature with its cooling effect. The combination of insert and holder significantly improves life.

- The WavyJoint insert boasts a large brazing contact area, resulting in high brazing strength. This design ensures exceptional reliability, even during intermittent cutting operations.

![]()

- BR35F is the material of choice for heavy interrupted cutting

- In heavy interrupted cutting of hardened steel, it achieves excellent fracture resistance