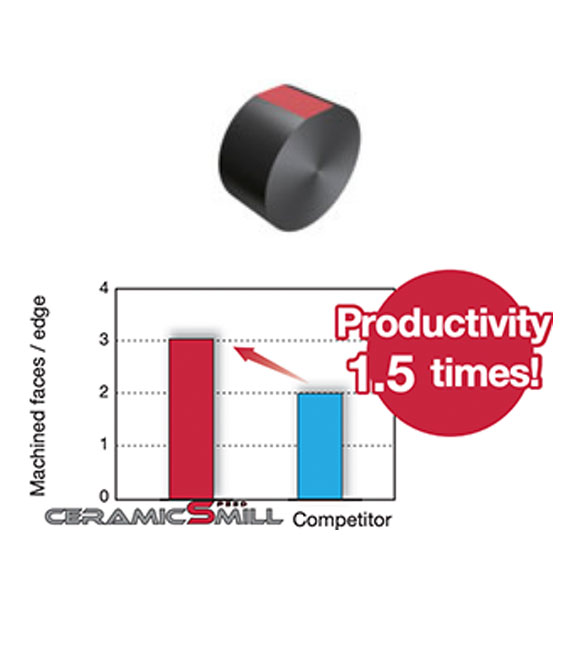

High efficiency milling cutter with ceramic inserts for high temperature alloy machining

New SiAlON grade inserts for high reliability. These two new ceramic grades are characterized by their excellent toughness and anti-chipping capabilities

Applications & Features

Applications

Features

1. New SiAlON grade inserts for high reliability

– Two new ceramic grades are characterized by their excellent toughness and anti-chipping capabilities.

TS200

– Superior wear resistance due to high chemical stability.

TS300

– Extreme toughness allows for higher cutting condition.

2. High efficiency milling cutter with ceramic inserts

Offers the most dense cutter.

Inserts & Grades

Inserts

RNGN-E/T1

- Maximum depth of cut: 2 mm

- SiAlON ceramic insert for high temperature alloy machining

Grades

TS200

![]()

- Superior wear resistance due to high chemical stability

- Superior flank and notch wear resistance

TS300

![]()

- Extreme toughness allows for higher feed and greater depth of cut machining

- Suitable for scaling and roughing applications

Cutter bodies

Practical examples

Example #1

Aerospace Industry

| Part: | Aircraft parts |

| Material: | INCONEL718 |

| Cutter: | TFMRN563-22R-12FL (ø63 mm, z = 5) |

| Insert: | RNGN120700E |

| Grade: | TS300 |

| Cutting conditions: | Vc = 500 (m/min) fz = 0.1 (mm/t) Vf = 1255 (mm/min) ap = 0.5 (mm) Application: Face milling Coolant: Dry Machine: Vertical M/C |

Standard cutting conditions

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|

| Ni-based super alloys | TS200 | 550 – 1300 | 0.05 – 0.2 | 0.1 – 2 | |

| TS300 | 270 – 550 | 0.05 – 0.2 | 0.1 – 2 | ||

| Co-based super alloys | TS200 | 550 – 1500 | 0.05 – 0.2 | 0.1 – 2 | |

| TS300 | 270 – 550 | 0.05 – 0.2 | 0.1 – 2 |

For more information about this product, visit our online e-catalog or download the product report: