Innovative Tool for Machining Efficiency and Tool Economy

Economico, con inserto a 10 taglienti, assicura la massima efficienza di lavorazione.

Applications & Features

Applications

Features

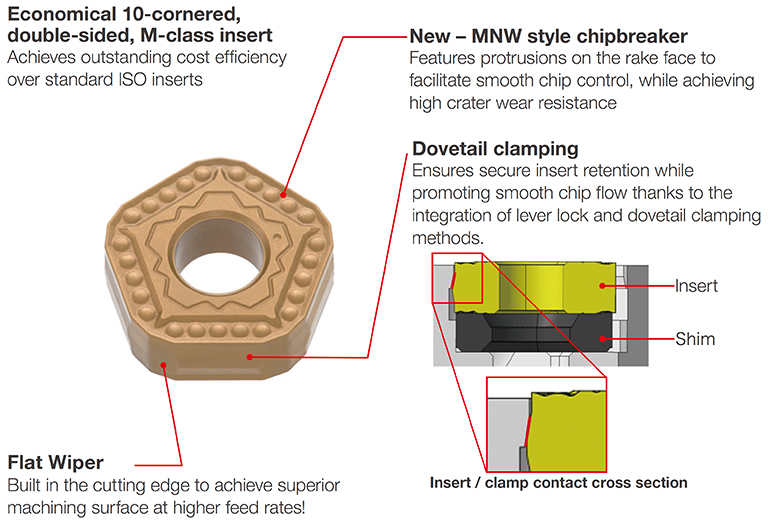

1. Economical 10-cornered, double-sided, M-class insert

Achieves outstanding cost efficiency over standard ISO inserts.

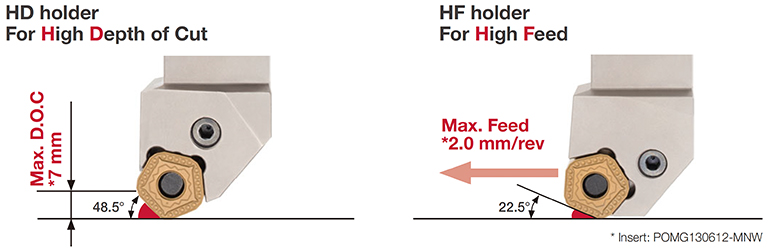

2. Features of Holders

Available in 2 types: – HD holder for large depths of cut – HF holder for high feed turning. Inserts are interchangeable between these two holders.

Inserts & Grades

Inserts

Grades

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T9225

![]()

- P15 – P25

- First choice for roughing to medium cutting

- High fracture resistance

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Toolholders

External turning

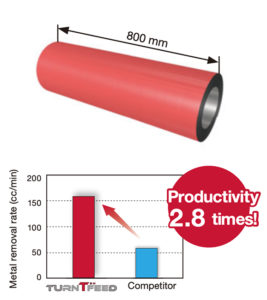

TurnTenFeed Toolholder for High Feed

Economical 10-cornered insert for high feed turning

External turning

TurnTenFeed Toolholder for High Depth of Cut

Economical 10-cornered insert for high feed turning

Practical examples

Example #1

General Engineering

| Part: | Machine parts |

| Material: | Alloy steel |

| Holder: | PPXOR3232P13-HD |

| Insert: | POMG130612-MNW |

| Grade: | T9225 |

| Cutting conditions: | Vc = 120 (m/min) f = 1.0 (mm/rev) ap = 4.5 (mm) Coolant: Wet |

Example #2

General Engineering

| Part: | Machine parts |

| Material: | C45, 1045 |

| Holder: | PPXOR3232P13-HF |

| Insert: | POMG130612-MNW |

| Grade: | T9215 |

| Cutting conditions: | Vc = 120 (m/min) f = 1.5 (mm/rev) ap = 1.2 (mm) Coolant: Wet |

Example #3

Heavy Industry

| Part: | Forged steel pipe |

| Material: | Inconel 925 |

| Holder: | PPXOR3232P13-HF |

| Insert: | POMG130612-MNW |

| Grade: | AH8015 |

| Cutting conditions: | Vc = 65 (m/min) f = 1.2 (mm/rev) ap = 2 (mm) Coolant: Wet |

Standard cutting conditions

For HD holder (High Depth of Cut)

| ISO | Insert | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|

| T9215 | T9225 | ||||

| POMG110612-MNW | 0.8 – 5.5 | 0.4 – 1.2 | 150 – 400 | 120 – 300 | |

| POMG130612-MNW | 1.0 – 7.0 | 0.4 – 1.3 | 150 – 400 | 120 – 300 | |

| ISO | Insert | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) |

|---|---|---|---|---|

| AH8015 | ||||

| POMG110612-MNW | 0.8 – 5.5 | 0.4 – 1.2 | 50 – 150 | |

| POMG130612-MNW | 1.0 – 7.0 | 0.4 – 1.3 | 50 – 150 | |

| POMG110612-MNW | 0.8 – 5.5 | 0.4 – 1.2 | 20 – 80 | |

| POMG130612-MNW | 1.0 – 7.0 | 0.4 – 1.3 | 20 – 80 |

For HF holder (High Feed)

| ISO | Insert | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|

| T9215 | T9225 | ||||

| POMG110612-MNW | 1.0 – 2.5 | 0.5 – 1.5 | 150 – 400 | 120 – 300 | |

| POMG130612-MNW | 1.0 – 3.0 | 0.5 – 2.0 | 150 – 400 | 120 – 300 | |

| ISO | Insert | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) |

|---|---|---|---|---|

| AH8015 | ||||

| POMG110612-MNW | 1.0 – 2.5 | 0.5 – 1.5 | 50 – 150 | |

| POMG130612-MNW | 1.0 – 3.0 | 0.5 – 2.0 | 50 – 150 | |

| POMG110612-MNW | 1.0 – 2.5 | 0.5 – 1.5 | 20 – 80 | |

| POMG130612-MNW | 1.0 – 3.0 | 0.5 – 2.0 | 20 – 80 |

indietro