Cermet grades for steel finishing turning

Cermet grades with remarkable stable tool life due to incredible fracture resistance

Applications & Features

Applications

Features

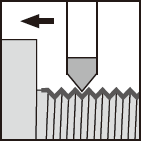

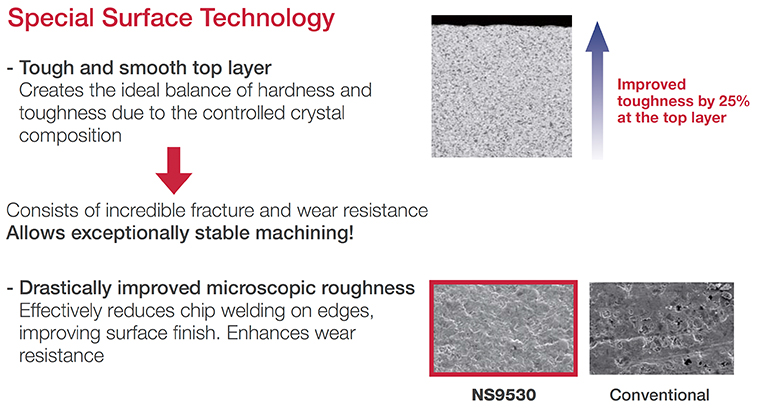

1. Special Surface Technology

Consists of incredible fracture and wear resistance for exceptionally stable machining!

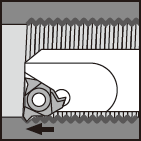

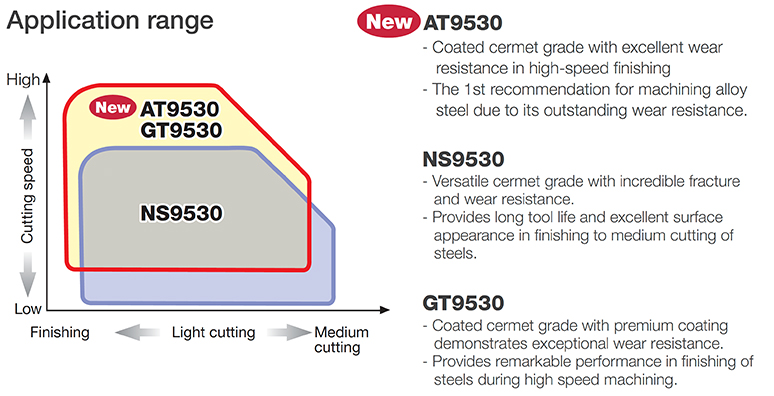

2. Application range

Gradi

NS9530

![]()

![]()

- High fracture resistance

- Suitable for finishing to medium cutting of steel

GT9530

![]()

![]()

- High wear resistance

- Excellent surface quality in finishing

AT9530

![]()

- High wear resistance

- First choice for machining alloy steel

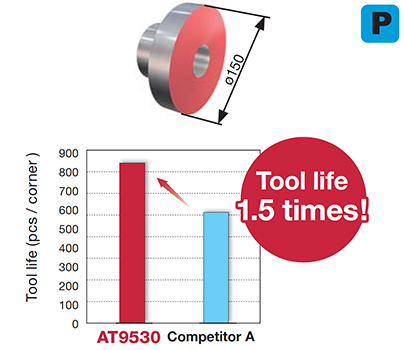

Practical examples

Example #1

General Engineering

| Part: | Rotor parts |

| Material: | Sintered material |

| Insert: | VNMG160402-TSF |

| Grade: | AT9530 |

| Cutting conditions: | Vc = 220 (m/min) f = 0.07 (mm/rev) ap = 0.5 (mm) Application: Face turning (Continuous cutting) Coolant: Wet |

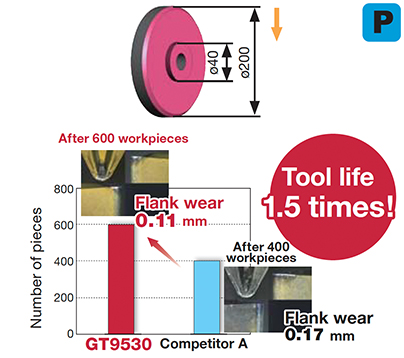

Example #2

Automotive Industry

| Part: | Automotive parts |

| Material: | SPCH |

| Insert: | DNMG150408-TSF |

| Grade: | GT9530 |

| Cutting conditions: | Vc = 225 (m/min) f = 0.25 (mm/rev) ap = 0.3 (mm) Application: Face turning (Continuous cutting) Coolant: Wet |

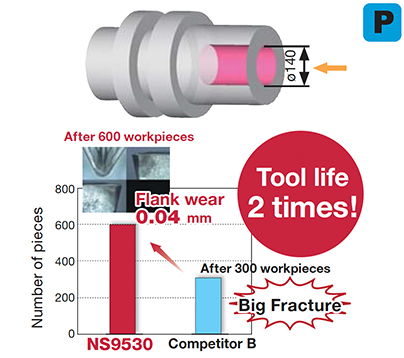

Example #3

Automotive Industry

| Part: | Automotive parts |

| Material: | SCM415 |

| Insert: | TPMT110304-PS |

| Grade: | NS9530 |

| Cutting conditions: | Vc = 125 (m/min) f = 0.15 (mm/rev) ap = 1.0 (mm) Application: Internal turning (Continuous cutting) Coolant: Wet |

Standard cutting conditions

NEGATIVE TYPE INSERTS

Basic chipbreaker

| Application | Chipbreaker | Grades | Cutting speedVc (m/min) | Depth of cut ap (mm) |

Feed f(mm/rev) |

||

|---|---|---|---|---|---|---|---|

| Low carbon steels Alloy steels 180HB |

Medium carbon steels Alloy steels 240HB |

High carbon steels Alloy steels 300HB |

|||||

| Precision finishing | TF | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 0.5 | 0.03 – 0.15 |

| Finishing | TSF | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 1.5 | 0.08 – 0.4 |

| AT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Finishing to medium cutting |

TS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.5 | 0.1 – 0.3 |

| AT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

Complementary chipbreakers

| Application | Chipbreaker | Grades | Cutting speedVc (m/min) | Depth of cut ap (mm) |

Feed f(mm/rev) |

||

|---|---|---|---|---|---|---|---|

| Low carbon steels Alloy steels 180HB |

Medium carbon steels Alloy steels 240HB |

High carbon steels Alloy steels 300HB |

|||||

| Precision finishing | 01 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 0.4 | 0.03 – 0.15 |

| A – D | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 4.0 | 0.1 – 0.4 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 1.5 | 0.03 – 0.2 | |

| Finishing | ZF | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 1.5 | 0.07 – 0.2 |

| AT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| 11 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 1.5 | 0.07 – 0.2 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| NS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 1.5 | 0.07 – 0.25 | |

| AFW | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 1.5 | 0.2 – 0.4 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| High feed, small depth of cut |

AS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.2 – 0.6 |

| ASW | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.3 – 0.6 | |

| Boring (Double sided chipbreaker) |

CB | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 2.5 | 0.1 – 0.25 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Finishing to medium cutting |

TQ | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.15 – 0.3 |

| AT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| ZM | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.7 – 2.0 | 0.15 – 0.4 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| NM | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.15 – 0.4 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Medium cutting | All-round | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 3.0 | 0.2 – 0.4 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Parallel | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 4.0 | 0.2 – 0.4 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| S | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 4.0 | 0.2 – 0.4 | |

| P | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 4.0 | 0.2 – 0.5 | |

POSITIVE TYPE INSERTS

Basic chipbreakers

| Application | Chipbreaker | Grades | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f(mm/rev) |

||

|---|---|---|---|---|---|---|---|

| Low carbon steels Alloy steels 180HB |

Medium carbon steels Alloy steels 240HB |

High carbon steels Alloy steels 300HB |

|||||

| Finishing | PSF | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 0.5 | 0.05 – 0.3 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Finishing to light cutting |

PSS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.1 – 0.3 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Finishing to medium cutting |

PS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.5 | 0.1 – 0.3 |

| AT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Medium cutting | PM | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 3.0 | 0.15 – 0.3 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

Complementary chipbreakers

| Application | Chipbreaker | Grades | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f(mm/rev) |

||

|---|---|---|---|---|---|---|---|

| Low carbon steels Alloy steels 180HB |

Medium carbon steels Alloy steels 240HB |

High carbon steels Alloy steels 300HB |

|||||

| Precision finishing |

01 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.05 – 0.5 | 0.03 – 0.15 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| Finishing | PF | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 0.5 | 0.05 – 0.25 |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W08 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 1.0 | 0.03 – 0.15 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W10 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.03 – 0.2 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W11 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.03 – 0.2 | |

| W13 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.03 – 0.2 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W15 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.03 – 0.2 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| W20 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.03 – 0.2 | |

| GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | ||||

| with hand | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 2.0 | 0.03 – 0.2 | |

| Finishing to medium cutting |

ZF | GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | 0.3 – 1.5 | 0.05 – 0.25 |

| ZM | GT9530 | 150 – 300 | 80 – 250 | 80 – 200 | 0.5 – 2.0 | 0.05 – 0.3 | |

| 23 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.1 – 0.3 | |

| SS | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 2.0 | 0.1 – 0.3 | |

| All-round | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 1.0 – 2.0 | 0.05 – 0.2 | |

| For external turning on small lathes | J10 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 5.0 | 0.01 – 0.1 |

| Medium cutting | 24 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.5 – 3.0 | 0.08 – 0.3 |

| Heavy cutting | 61 | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.2 – 2.0 | 0.3 – 1.0 |

| Finishing to medium cutting | – | NS9530 | 150 – 250 | 80 – 220 | 80 – 180 | 0.1 – 2.0 | 0.05 – 0.3 |

JS, JP Chipbreaker

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) | Depth of cut ap (mm) | Feed:f (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| RE < 0.05 | RE < 0.1 | RE < 0.2 | RE < 0.4 | ||||||

|

Carbon steel Alloy steel |

JP | NS9530 | 150 – 250 | 0.05 – 2.5 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | – |

| AT9530 | 150 – 300 | 0.05 – 2.5 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | – | |||

| JS | NS9530 | 150 – 250 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | ||

| AT9530 | 150 – 300 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | |||

For more information about this product, visit our online e-catalog or download the product report: