![]()

A modular system for milling

Various types of modular heads can be combined with different shanks and holders for multiple application needs.

Applications & Features

Applications

Features

1. Quick and slim connection

• Screw clamp head type promotes easy tool management.

• Suitable for deep machining of metal molds due to the slim structure.

• Provides wide machining variations with numerous combinations.

• Provides high rigidity similar to integrated type holders.

Inserts & Grades

Inserts

LSMT-HM

- Maximum depth of cut = 0.5 mm

- Provides machining efficiency in a wide range of applications

- First choice insert for various applications including slotting, pocketing, or long reach areas

LNMX-MJ/ML (R4, R5, R6)

- 4 corners radius insert with high reliability

TO*T-MJ/AJ/NMJ

- Maximum depth of cut = 15 mm (15 size insert)

- Economical 3 cutting-edge inserts with low cutting force

Main Grades

AH3225

![]()

![]()

- High chipping and fracture resistance

- Suitable for milling steel and stainless steel

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Tool Bodies

Practical examples

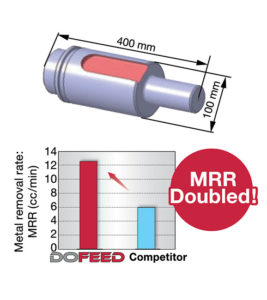

Example #1

xxx Industry

| Part: | Shaft |

| Material: | Inconel 625 |

| Cutter: | HXN03R032MM16-06 (ø32, z = 6) |

| Insert: | LNMU0303ZER-ML |

| Grade: | AH130 |

| Cutting conditions: | Vc = 35 (m/min) fz = 0.45 (mm/t) ap = 0.44 (mm) ae = 30 (mm) |

| Process: | Slot milling, Wet |

| Machine: | Vertical M/C, BT50 |

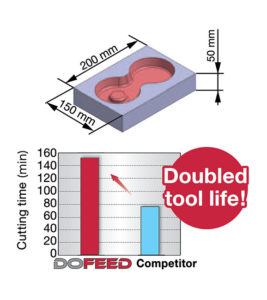

Example #2

xxx Industry

| Part: | Die & mould |

| Material: | FCD600 / GGG60 |

| Cutter: | HXN03R020MM10-04 (ø20, z = 4) |

| Insert: | LNMU0303ZER-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 190 (m/min) fz = 0.4 (mm/t) ap = 0.3 (mm) ae = 9 (mm) |

| Process: | Pocket milling, Dry (air) |

| Machine: | Vertical M/C, BT40 |

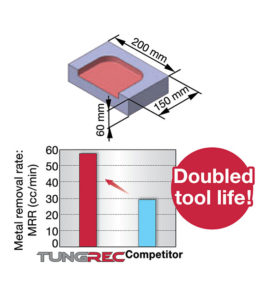

Example #3

xxx Industry

| Part: | Mould for injection |

| Material: | NAK50 |

| Cutter: | HPO07R020MM10-05 (ø20, z = 5) |

| Insert: | AOMT070208PDPR-HJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 120 (m/min) fz = 0.4 (mm/t) ap = 0.5 (mm) ae = 20 (mm) |

| Process: | Pocket milling, Dry (air) |

| Machine: | Vertical M/C, BT40 |

For more information about this product, visit our online e-catalog or download the product report: