High speed face milling cutter for finishing aluminum

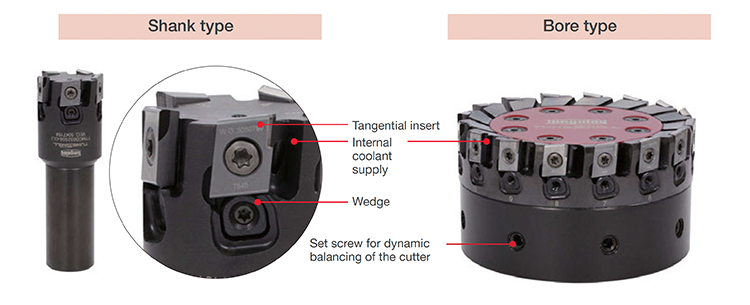

TungSpeed-Mill with tangentially clamped inserts for improved face milling efficiency

Applications & Features

Applications

Features

- High density for high speed milling

- Tangential inserts create stronger insert orientation and higher productivity

- Cutter bodies are available in shell mill (bore) type in ø50 mm and larger and cylindrical (shank) type in ø40 mm and smaller

- PCD inserts come in various geometries including double-edged and long-edge styles

Tough body for high performance

The cutter body is made of part steel for secure insert clamping and durability and part aluminum for reduced cutter weight. Titanium body is also available upon request for higher durability and lighter weight.

Inserts & Grades

Inserts

YPEB12X3-1A

- Cutting edge length = 4 mm

- Grade: DX160

- General purpose

YPEB12X3-2A/P

- Cutting edge length = 4 mm

- Grade: DX160

- Economical

YPEB12X-FP

- Cutting edge length = 11 mm

- Grade: DX160

- Long cutting edge length for deep depth of cut

Grades

Cutter bodies

Practical examples

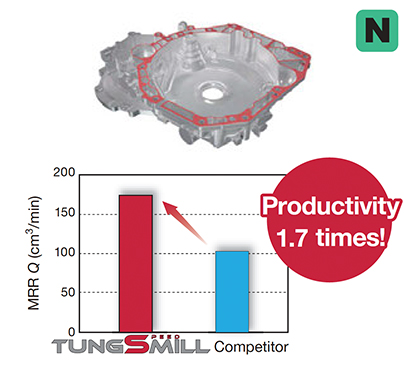

Example #1

Automotive Industry

| Part: | Case |

| Material: | ADC12 |

| Cutter: | Special tool (ø32 mm, z = 5) |

| Insert: | YPEB12X3-1A07R-D |

| Grade: | DX160 |

| Cutting conditions: | Vc = 1,000 (m/min) fz = 0.07 (mm/t) ap = 2 (mm) ae = 25 (mm) Coolant: Wet (Internal) |

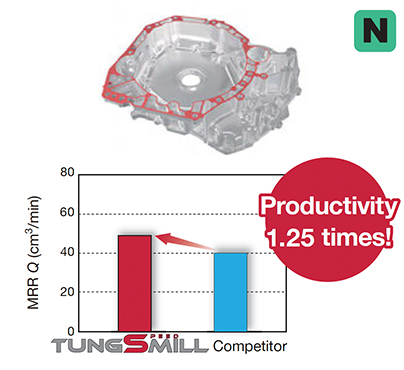

Example #2

Automotive Industry

| Part: | Housing |

| Material: | ADC12 |

| Cutter: | Special tool (ø32 mm, z = 5) |

| Insert: | YPEB12X3-1A07R-D |

| Grade: | DX160 |

| Cutting conditions: | Vc = 1,000 (m/min) fz = 0.02 (mm/t) ap = 2 (mm) ae = 25 (mm) Coolant: Wet (Internal) |

Standard cutting conditions

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

| Aluminum cast Si < 13% |

DX160 | ≤ 6000 | 0.05 – 0.25 | |

| Aluminum cast Si ≥ 13% |

DX160 | ≤ 1500 | 0.05 – 0.25 | |

| Copper, brass, etc. | DX160 | ≤ 2000 | 0.05 – 0.25 | |

| Non metalic material | DX160 | ≤ 3000 | 0.05 – 0.25 |

indietro