Excellent surface finish and wall accuracy in shoulder milling

Helical cutting edge and large axial rake angle on insert provide smooth cutting in semi-finishing operation

Applications & Features

Applications

Features

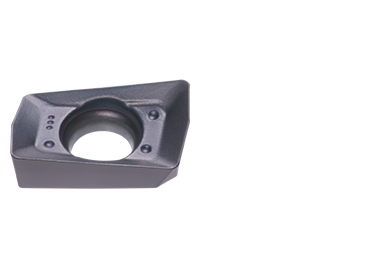

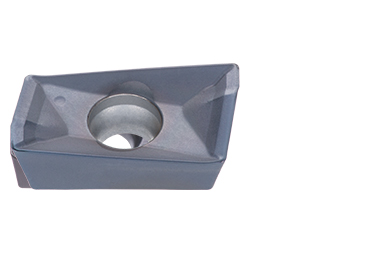

1. Inserts

• Helical cutting edge for high wall accuracy.

• Wiper edge for excellent surface finish.

• Optimized rake angle for sharpness and reliability.

• 4 chipbreaker types for a wide range of applications.

• Corner radius range up to 3.2 mm (0.126″).

• Available in DLC coating and cermet inserts.

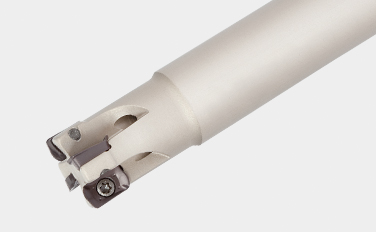

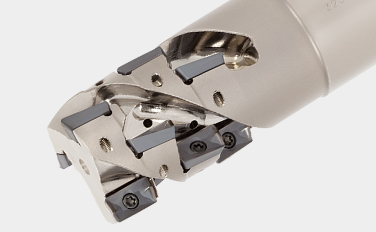

2. Cutter body

• Air holes for improved chip evacuation.

• Available in coarse- and close-pitch, and long shank cutters.

Inserts & Grades

Inserts

AO*T07/18

- Maximum depth of cut

– AO*T07: 7 mm

– AO*T18: 16.7 mm

AS*T11

- Maximum depth of cut: 10.6 mm

Main Grades

AH725

![]()

![]()

![]()

![]()

- PVD Coated Grade for general purpose of machining steel & stainless in a wide variety of applications

AH140

![]()

![]()

![]()

- PVD Coated Grade for milling of stainless steels at low speeds

KS15F

![]()

- Uncoated cemented carbide

Cutter bodies

Shank Type

EPO (ø12 – ø63mm)

High precision shoulder square endmills

- EPO07

– Tool dia.: ø12 – ø28 mm

– Insert: AO*T07 - EPO11

– Tool dia.: ø12 – ø50 mm

– Insert: AS*T11 - EPO18

– Tool dia.: ø25 – ø63 mm

– Insert: AO*T18

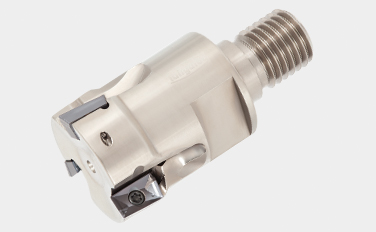

Modular Type

HPO (ø12 – ø32mm)

High precision shoulder square endmills (TungRec) with TungFlex

- HPO07

– Tool dia.: ø12 – ø25 mm

– Insert: AO*T07 - HPO11

– Tool dia.: ø20 – ø32 mm

– Insert: AS*T11

Bore Type

TPO (ø32 – ø160 mm)

High precision shoulder square mills

- TPO07

– Tool dia.: ø32 – ø50mm

– Insert: AO*T07 - TPO11

– Tool dia.: ø40 – 100 mm

– Insert: AS*T11 - TPO18

– Tool dia.: ø40 – ø160mm

– Insert: AO*T18

Bore Type

TLS11 (ø50mm)

Highly productive shoulder square mills for roughing

– Insert: AS*T11

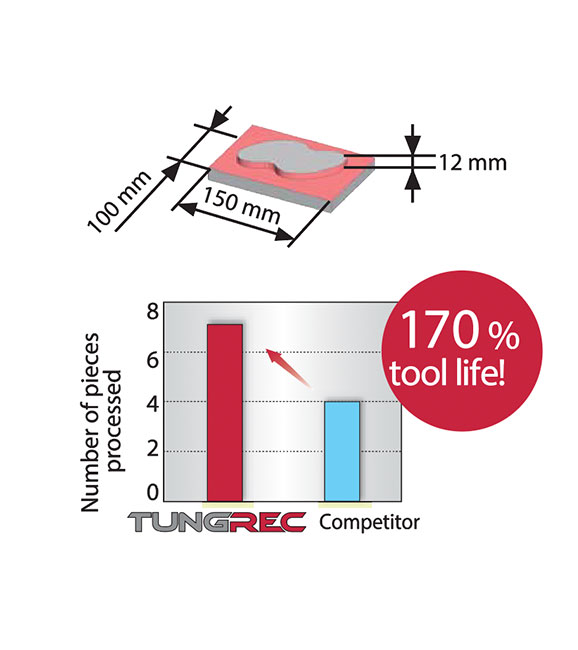

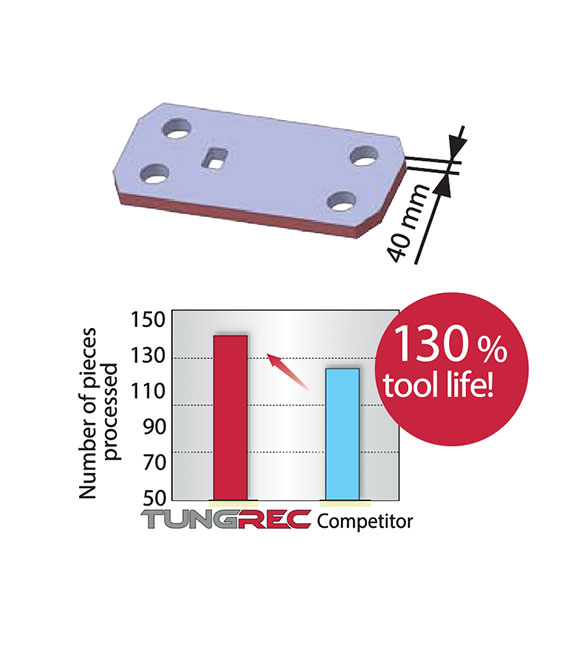

Practical examples

Example #1

General Engineering

| Part: | Machine parts |

| Material: | SCM440 / 42CrMo4 |

| Cutter: | TPO07R040M16.0E10 (ø40, z = 10) |

| Insert: | AOMT070208PDPR-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 130 (m/min) fz = 0.1 (mm/t) Vf = 1000 (mm/min) ap = 3.0 (mm) ae = ~ 30 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical MC, BT40 |

Example #2

General Engineering

| Part: | Compressor parts |

| Material: | SS400 / E275A |

| Cutter: | EPS11033RSB (ø33, z = 5) |

| Insert: | ASMT11T304PDPR-MJ |

| Grade: | NS740 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.13 (mm/t) Vf = 940 (mm/min) ap = 5 (mm) ae = 15 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical MC, BT50 |

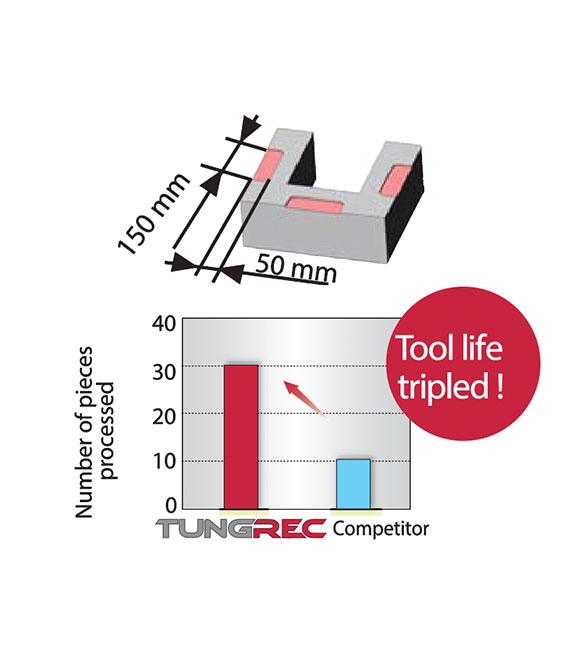

Example #3

General Engineering

| Part: | Machine parts |

| Material: | SS400 / E275A |

| Cutter: | TLS11R050M22.0E04 |

| Insert: | ASMT11T308PDPR-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.17 (mm/t) Vf = 649 (mm/min) ap = 40 (mm) ae = 5 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical MC, BT50 |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: