Ideal tool for milling small parts on small machines

Small-diameter, extra close-pitch cutter body is highly rigid and provides excellent chip evacuation. Positive insert with 4 cutting-edge delivers economical advantage

Applications & Features

Applications

Features

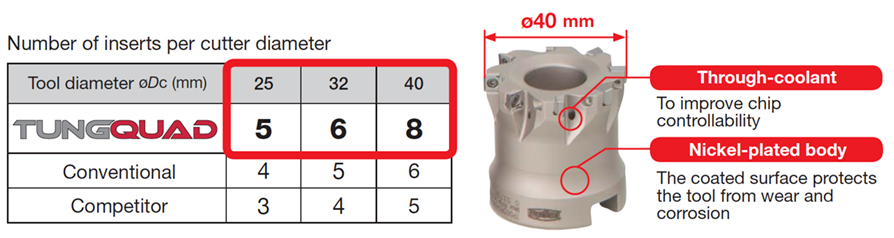

1. High insert density for maximum productivity

A small diameter square shoulder mill with close-pitched insert orientations enables a high product output in various materials.

2. Optimized insert geometry

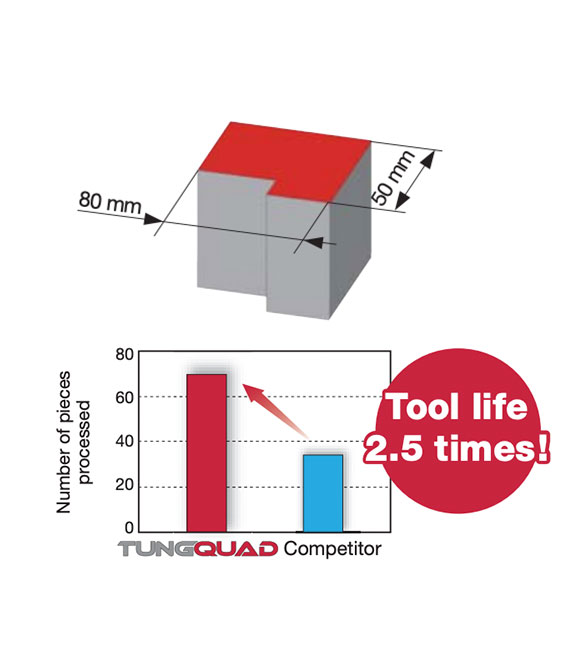

Inserts & Grades

Inserts

Grades

AH140

![]()

- PVD Coated Grade for milling of stainless steels at low speeds

AH725

![]()

![]()

![]()

![]()

- PVD Coated Grade for general purpose of machining steel & stainless in a wide variety of applications

TH10

![]()

- Uncoated cemented carbide

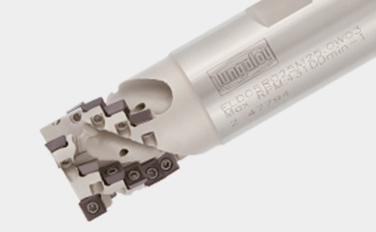

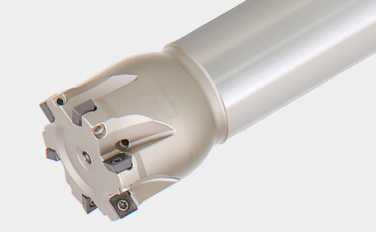

Cutter bodies

Shank Type

ELD05 (ø20 – ø25mm)

Highly dense shoulder square endmills for roughing with small SDMT05 inserts

Shank Type

EPD05 (ø12 – ø40mm)

Highly dense shoulder square endmills with small SDMT05 inserts

Bore Type

TPD05 (ø32 / ø40mm)

Highly dense square shoulder mills with small SDMT/SDHT05 inserts

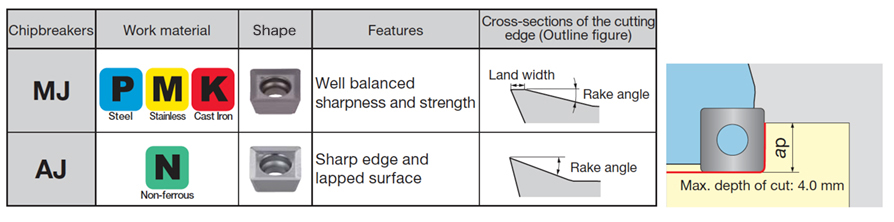

Practical examples

Example #1

General Engineering

| Part: | Compressor parts |

| Material: | Aluminium alloys ADC12 |

| Cutter: | EPD05R025M20.0W05 |

| Insert: | SDHT050204FN-AJ |

| Grade: | TH10 |

| Cutting conditions: | Vc = 314 (m/min) fz = 0.08 (mm/t) Vf = 1500 (mm/min) ap = 1 (mm) ae = 25 (mm) Application: Shoulder milling Coolant: Wet Machine: BT30 |

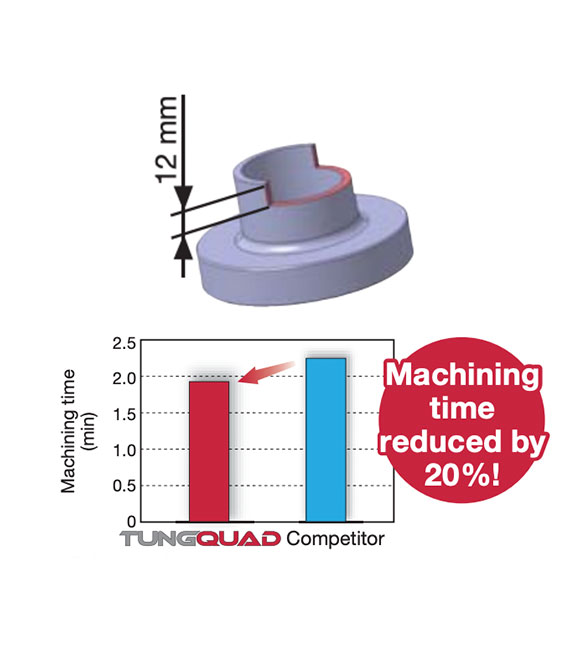

Example #2

General Engineering

| Part: | Machine parts |

| Material: | Stainless steels SUS304 / X5CrNi18-9 |

| Cutter: | EPD05R040M32.0W08 |

| Insert: | SDMT050204PN-MJ |

| Grade: | AH140 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.06 (mm/t) Vf = 573 (mm/min) ap = 3.5 (mm) ae = 2 (mm) Application: Shoulder milling Coolant: Dry Machine: BT40 |

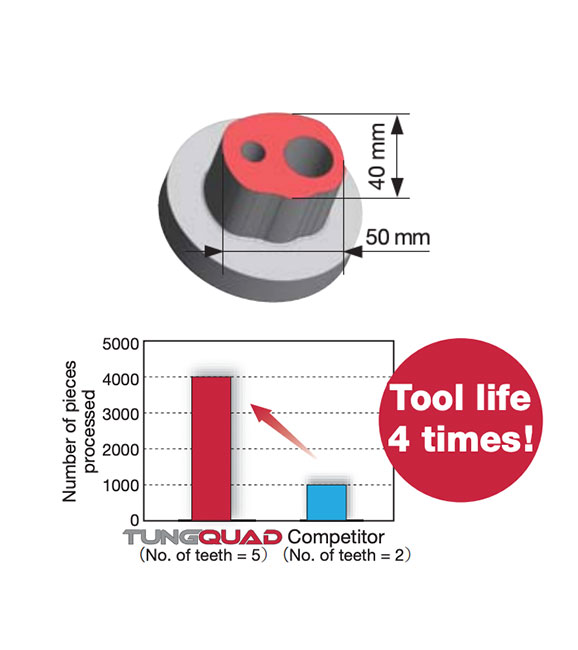

Example #3

General Engineering

| Part: | Cover of machine |

| Material: | SCM440 / 42CrMo4 |

| Cutter: | ELD05R020M20.0W02 (ø20, z = 2) |

| Insert: | SDMT050204PN-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 100 (m/min) fz = 0.07 (mm/t) Vf = 230 (mm/min) ap = 12 (mm) ae = 6 × 3 passes (mm) Application: Shoulder milling Coolant: Wet Machine: Multi-axis machine BT40 |

Standard cutting conditions

indietro