Easy-to-index milling cutters for superior surface quality

High reliability, stability, and efficiency

Applications & Features

Applications

Features

Excellent surface quality

- No axial/radial run-out adjustments needed.

- The insert pockets are designed so that the finishing insert always performs the finishing, providing consistent surface roughness.

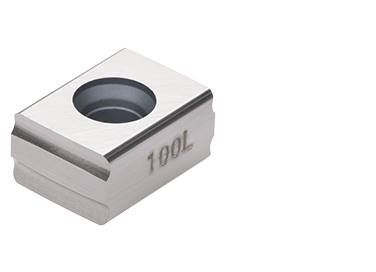

- Light cutting geometry with wiper edge incorporating a great circular arc.

First choice

- Provides superior surface quality

Light cutting

- Generates light cutting action with excellent surface finishing thanks to the same wiper geometry as the LNCQ0906N-100L.

For super light cutting / Finishing close to the shoulders

- Reduced radial force

- Allows minimum interference with the shoulders when machining into the Cutting force work corners

Optimizing the insert combinations for workpieces with thin walls or shoulders

Inserts & Grades

Inserts

Grades

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

GH110

![]()

![]()

![]()

![]()

![]()

- High wear resistance

NS740

![]()

- High resistance to fracture and thermal crack

- High-rigidity grade for milling

Cutter

Practical examples

Example #1

| Workpiece type: | Part for expansion chamber |

| Workpiece material: | SUS304 / X5CrNi18-9 |

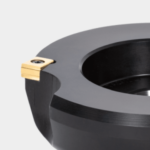

| Cutter: | NMS09160R |

| Insert: | LNCQ0906N-100L |

| Grade: | AH120 |

| Cutting conditions: | Vc = 180 (m/min) f = 3 (mm/rev) ap = 0.1 (mm) ae = 130 (mm) Machining: Face Milling Coolant: External Machine: Horizontal M/C BT50 |

Example #2

| Workpiece type: | Cylinder block |

| Workpiece material: | FC250 / 250 |

| Cutter: | NMS09160R |

| Insert: | LNCQ0906N-100L |

| Grade: | AH120 |

| Cutting conditions: | Vc = 200 (m/min) f = 3 (mm/rev) ap = 0.15 (mm) ae = 110 (mm) Machining: Face milling Coolant: Dry Machine: Vertical M/C BT50 |

Example #3

| Workpiece type: | Plate |

| Workpiece material: | SCM440 / 42CrMo4 |

| Cutter: | NMS09160R |

| Insert: | LNCQ0906N-100L |

| Grade: | NS740 |

| Cutting conditions: | Vc = 200 (m/min) f = 2 (mm/rev) ap = 0.1 (mm) ae = 110 (mm) Machining: Face milling Coolnat: Dry Machine: Vertical M/C BT50 |

Standard cutting conditions

| ISO | Workpiece material | Hardness (HB) |

Grade | Cutting speed Vc (m/min) |

LNCQ0906N-100(50)L | LNCQ0906R-50S | ||

|---|---|---|---|---|---|---|---|---|

| Depth of cut APMX (mm) |

Feed per tooth f (mm/rev) |

Depth of cut APMX (mm) |

Feed per tooth f (mm/rev) |

|||||

|

Mild steels SS400, etc. E275A, etc. |

< 180 | NS740 | 200 – 300 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

| Carbon steels S55C, etc. C55, etc. |

< 300 | NS740 | 150 – 250 | |||||

| Alloy steels SCM440, etc. 42CrMo4, etc. |

< 300 | NS740 | 120 – 200 | |||||

| Die steels SKD61, etc. X40CrMoV5-1, etc. |

< 300 | NS740 | 100 – 150 | |||||

|

Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

< 250 | AH120 NS740 |

150 – 220 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

|

Cast irons FC250, etc. 250, etc. |

150 – 250 | GH110 AH120 |

120 – 200 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

For more information about this product, visit our online e-catalog or download the product report: