Ideal for steel and cast iron face milling

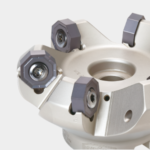

A single cutter body with 4 insert options broadens its application range

Applications & Features

Applications

Features

1. Inserts are available in single-sided or double-sided geometry

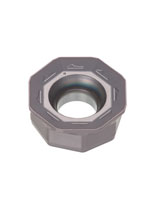

- ONMU / ONHU: Double-sided, octagonal inserts (economy)

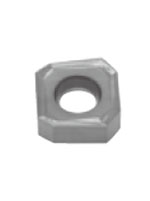

- SNMU / SNHU: Double-sided, square inserts (large cutting depths)

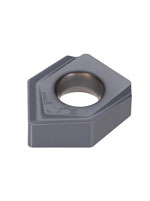

- OWMT: Single-sided, octagonal insert (with low cutting load, high feed rates)

2. Enhanced cutter body lineup

• Including cutter diameters of >ø315 mm or extra close pitched design for effective cast iron milling.

For general purpose

Optimized orientation of coolant outlet which is located in a large chip gullet facilitates smooth chip evacuation. Large clamping screw enhances insert security.

Cutter diameters: ø80 mm – ø315 mm

For efficient cast iron milling

Offers twice as much insert density as a screw clamping style cutter with easy indexability.

Cutter diameters: ø80 mm – ø160 mm

Inserts & Grades

Inserts

ONHU07-W

- Wiper insert with 8 cutting edges for ONMU/ONHU inserts

ON*U07-MJ / -ML

- Economical Double sided octagonal insert, 16 corners available

OWMT08-HJ

- Octagonal Milling Inserts with Positive Rake and HJ chipbreaker, 8 corners available

OWMT08-ML

- Octagonal Milling Inserts with Positive Rake and ML chipbreaker, 8 corners available

SNHU17-W

- Double sided wiper insert with 2 cutting edges in using with SNMU/SNHU insert

SN*U17-MJ / -ML

- Double sided square inserts with large depth of cut

Main Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

T3225

![]()

![]()

- High chipping and fracture resistance

- Suitable for milling steel and stainless steel

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

Cutter bodies

Bore Type

TAN07 (ø63 – ø315mm)

45deg screw clamp type face mills with double sided octagonal or square inserts

Bore Type

TAN07-W (ø63 – ø200mm)

45deg wedge clamp type face mills with double sided octagonal or square inserts

Practical examples

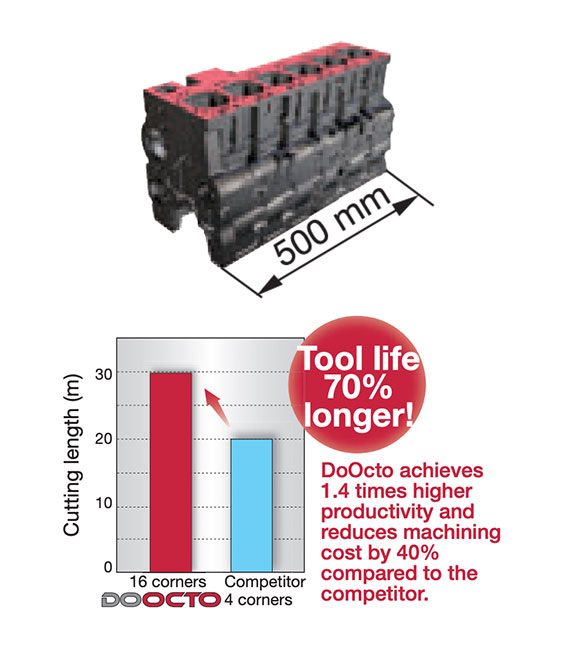

Example #1

Automotive Industry

| Part: | Cylinder block |

| Material: | FC250 |

| Cutter: | TAN07R160M50.8-15 (ø160 mm, z = 15) |

| Insert: | ONHU0705ANTN-ML |

| Grade: | AH120 |

| Cutting conditions: | Vc = 180 (m/min) fz = 0.18 → 0.2 (mm/t) Vf = 780 → 1080 (mm/min) ap = 3 (mm) ae = 100 (mm) Application: Face milling Coolant: Dry Machine: Vertical M/C, BT50 |

Example #2

Automotive Industry

| Part: | Crank shaft |

| Material: | SCM435 / 34CrMo4 |

| Cutter: | TAN07R100M31.7-07 (ø100 mm, z = 7) |

| Insert: | ONMU0705ANPN-ML |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 80 (m/min) fz = 0.18 (mm/t) Vf = 320 (mm/min) ap = 3 (mm) ae = 75 (mm) Application: Face milling Coolant: Wet Machine: Specialized machine |

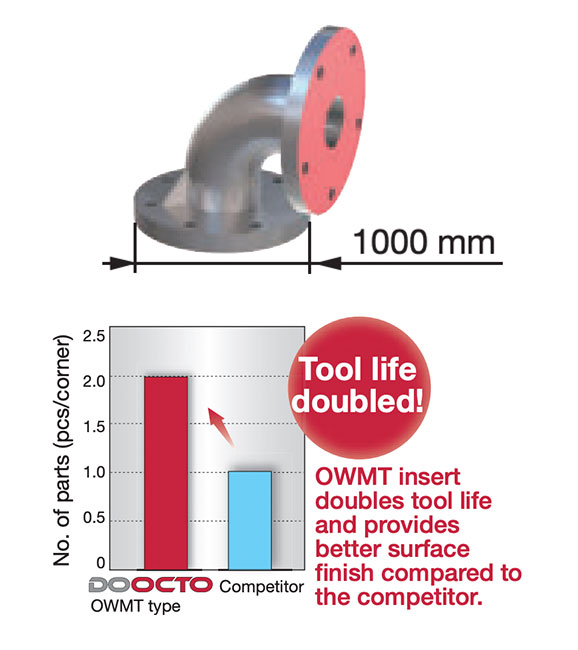

Example #3

General Engineering

| Part: | Elbow |

| Material: | SCS10 / 25Cr5NiMoN |

| Cutter: | TAN07R200M47.6-12 (ø200 mm, z = 12) |

| Insert: | OWMT0807AAER-ML |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 70 (m/min) fz = 0.2 (mm/t) Vf = 267 (mm/min) ap = 1 (mm) ae = 180 (mm) Application: Face milling Coolant: Wet Machine: Horizontal M/C, BT50 |

Standard cutting conditions

Negative type

| ISO | Workpiece material | Hardness | Priority | Recommendation | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|

| Grade | Chipbreaker | ||||||

| Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200HB | First choice | AH3225 | MJ | 100 – 250 | 0.2 – 0.5 | |

| – 200HB | Fracture resistance | AH3135 | MJ | 100 – 250 | 0.2 – 0.5 | ||

| – 200HB | Wear resistance | T3225 | MJ | 200 – 350 | 0.2 – 0.4 | ||

| – 200HB | Low cutting force | AH3225 | ML | 100 – 250 | 0.2 – 0.4 | ||

| High carbon steel S45C, S55C, etc. C45, C55, etc. |

200 – 300 HB | First choice | AH3225 | MJ | 100 – 230 | 0.2 – 0.4 | |

| 200 – 300 HB | Fracture resistance | AH3135 | MJ | 100 – 230 | 0.2 – 0.4 | ||

| 200 – 300 HB | Wear resistance | T3225 | MJ | 180 – 300 | 0.2 – 0.4 | ||

| 200 – 300 HB | Low cutting force | AH3225 | ML | 100 – 230 | 0.2 – 0.4 | ||

| Alloy steel SCM440, SCr415, etc. 42CrMo4, 17Cr3, etc. |

150 – 330 HB | First choice | AH3225 | MJ | 100 – 200 | 0.2 – 0.4 | |

| 150 – 330 HB | Fracture resistance | AH3135 | MJ | 100 – 200 | 0.2 – 0.4 | ||

| 150 – 330 HB | Wear resistance | T3225 | MJ | 150 – 250 | 0.2 – 0.4 | ||

| 150 – 330 HB | Low cutting force | AH3225 | ML | 100 – 200 | 0.2 – 0.4 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | AH3135 | MJ | 100 – 200 | 0.1 – 0.3 | |

| – 200HB | Wear resistance | T3225 | MJ | 100 – 250 | 0.1 – 0.3 | ||

| Grey cast iron FC350, FC450 etc. GG35, GG45, etc. |

150 – 250HB | First choice | AH8015 | MJ | 100 – 250 | 0.1 – 0.5 | |

| 150 – 250HB | Wear resistance | T1215 | MJ | 150 – 300 | 0.1 – 0.5 | ||

| 150 – 250HB | Low cutting force | AH8015 | ML | 100 – 250 | 0.1 – 0.5 | ||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 300HB | First choice | AH8015 | MJ | 80 – 200 | 0.1 – 0.5 | |

| 150 – 300HB | Wear resistance | T1215 | MJ | 100 – 300 | 0.1 – 0.5 | ||

| 150 – 300HB | Low cutting force | AH8015 | ML | 80 – 200 | 0.1 – 0.5 | ||

| Titanium alloy Ti-6Al-4V, etc. |

– HRC 40 | First choice | AH3135 | ML | 30 – 60 | 0.1 – 0.3 | |

| Heat resistant alloy Inconel718, etc. |

– HRC 40 | First choice | AH8015 | ML | 10 – 40 | 0.05 – 0.15 | |

| Hardened steel | 40 – 50HRC | First choice | AH8015 | MJ | 80 – 130 | 0.1 – 0.2 | |

| 40 – 50HRC | Fracture resistance | AH3225 | MJ | 80 – 130 | 0.1 – 0.2 | ||

| 50 – 60HRC | First choice | AH8015 | MJ | 50 – 70 | 0.05 – 0.1 | ||

Positive type

| ISO | Workpiece material | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) | |

|---|---|---|---|---|---|---|---|

| ML | HJ* | ||||||

| Low carbon steel S15C, SS400, etc. C15E, etc. |

– 200HB | First choice | AH3135 | 100 – 300 | 0.1 – 0.4 | 0.5 – 1.5 | |

| High carbon steel S45C, S55C, etc. C45, C55, etc. |

200 – 300 HB | First choice | AH3135 | 100 – 230 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Alloy steel SCM440, SCr415, etc. 42CrMo4, 17Cr3, etc. |

150 – 330 HB | First choice | AH3135 | 100 – 200 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | AH3135 | 100 – 150 | 0.1 – 0.3 | 0.3 – 0.7 | |

| – 200HB | Fracture resistance | AH130 | 100 – 150 | 0.1 – 0.3 | – | ||

| Grey cast iron FC350, FC450 etc. GG35, GG45, etc. |

150 – 250HB | First choice | AH3135 | 100 – 250 | 0.1 – 0.4 | 0.5 – 1.5 | |

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | AH3135 | 80 – 200 | 0.1 – 0.3 | 0.5 – 1.5 | |

| Titanium alloy Ti-6Al-4V, etc. |

– HRC 40 | First choice | AH3135 | 30 – 60 | 0.1 – 0.3 | 0.3 – 0.7 | |

| – HRC 40 | Fracture resistance | AH130 | 30 – 60 | 0.1 – 0.3 | – | ||

| Heat resistant alloy Inconel718, etc. |

– HRC 40 | First choice | AH3135 | 10 – 40 | 0.05 – 0.15 | 0.1 – 0.3 | |

| – HRC 40 | Fracture resistance | AH130 | 10 – 40 | 0.05 – 0.15 | – | ||

| Hardened steel | 40 – 50HRC | First choice | AH3135 | 80 – 130 | – | 0.1 – 0.3 | |

| 50 – 60HRC | First choice | AH3135 | 50 – 70 | – | 0.03 – 0.07 | ||

indietro