Iwaki, October 2020 — Tungaloy has added three new insert grades to its TungRec-11 series of high precision square shoulder milling cutters.

TungRec-11 features light cutting, two edged positive inserts for precision shoulder milling operations. TungRec-11 provides high wall accuracy and straightness thanks to the high helix geometry. Its also 3D milling capability allows the cutter to handle various types of ramping down and circular interpolating operations including opening up cavities and pockets.

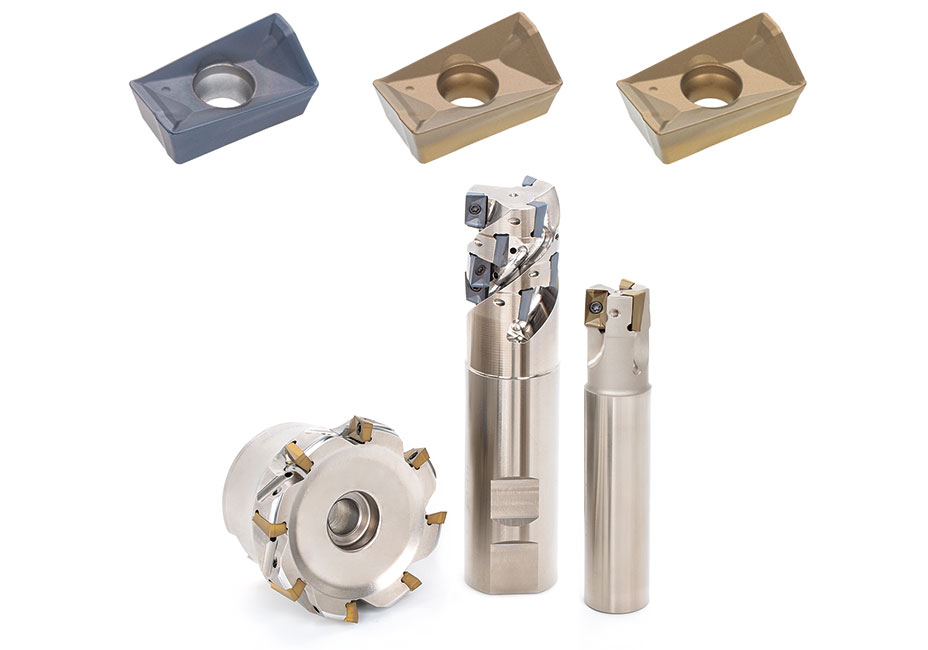

The inserts are available in three geometries and in six nose radii options ranging from 0.4 mm to 3.0 mm (.016″ – .118″). The cutter bodies come in cylindrical and shell mill variations, as well as in modular systems to address various shoulder milling operation needs.

The latest insert grade additions include one PVD and two CVD grades: AH3225 offers superior coating substrate adhesion that enhances the grade’s wear and fracture resistance, making this PVD grade the first choice in steel and stainless steel. CVD grade T3225 incorporates the latest post coating treatment technology, providing the grade with increased coating surface smoothness and strength against fracture during high speed machining of steel and stainless steel. In addition, T1215 offers a good balance of wear and fracture resistance, making this CVD grade ideal when machining cast iron at elevated speeds.