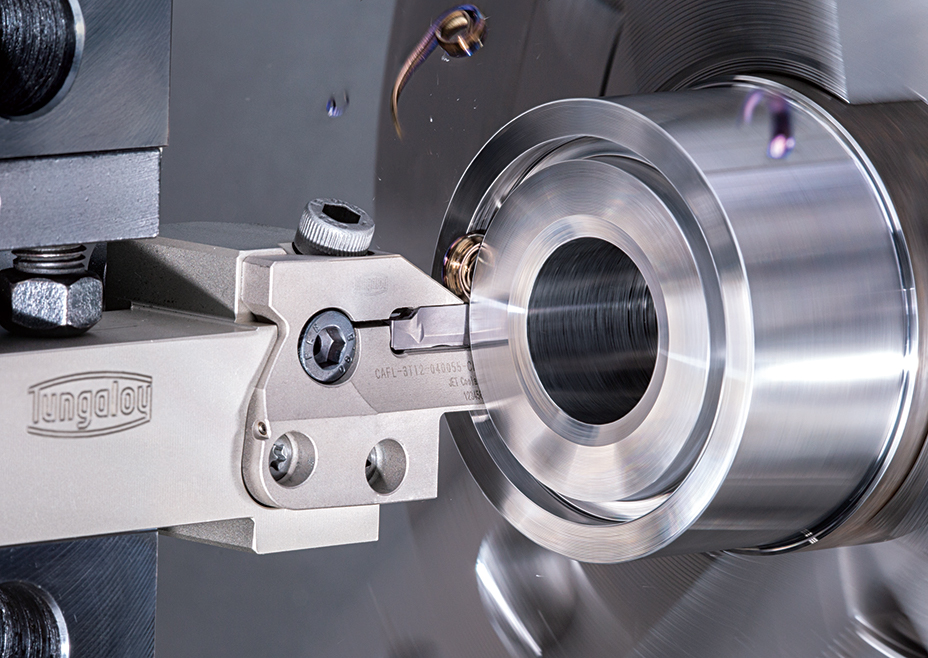

Iwaki, May 2021 — Tungaloy has expanded its TungCut grooving and parting tool system by adding 50 new modular adapters for face and OD grooving applications.

The TungCut line of multifunctional grooving and parting tools offers a broad range of insert and toolholder variations, including the TungModularSystem modular tooling solutions, to address the needs of all grooving and parting operations. When combined with the TungModularSystem of adapters and holders, TungCut can provide manufacturers with improved cost efficiency and reduced tool change and setup time, which was challenging with standard monoblock tooling.

New modular adapters for face grooving are designed with through-coolant capability for groove widths ranging from 3 to 6 mm (.118″ to .236″) and depths of up to 25 mm (1″). The adapters can effectively and precisely deliver coolant jet to the cutting edge during deep grooving operations for improved chip evacuation and process security.

For general OD grooving operations that do not always call for costly internal coolant capability, TungCut also offers modular adapters in simpler, cost-efficient design

without internal coolant channels that serves the usability requirements when dry-cutting OD grooves with a light depth of cut.

The new modular adapters provide increased rigidity as the blade is fastened onto the holder with multiple screws, one of which also works to clamp the insert, providing process security during aggressive grooving operation. All these new adapters can be mounted on existing TungModularSystem holders.

To address the needs of large-size component manufacturers, a modular adapter for 8 mm (.315″)-width insert has also been added to the line, available with or without through-coolant supply capacity.

Product information

No. 391S4-G (Metric)