Iwaki, Japan – December, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its Solid Thread line, introducing a new step‑release design that reduces cutting resistance and enhances stability and tool life for high‑precision, high‑efficiency thread milling across diverse materials.

Challenges and Trends

In recent years, various industries such as aerospace, medical, automotive parts, and molds have increasingly adopted high-strength materials and heat-resistant alloys. While these materials provide superior performance, they also exhibit poor machinability, often causing issues such as chip entanglement and tap breakage during threading operations. As a result, the shift toward thread milling for more stable machining and higher reliability has been accelerating. In the market, there is a growing demand for solutions that enhance productivity by reducing machining time and extending tool life.

Product Overview

ThreadMilling is a thread milling tool that enables high-precision internal threading on CNC machining centers. By utilizing helical interpolation, it supports both right-hand and left-hand threads. The tool minimizes deviations caused by wear, ensuring stable thread profile formation. Compatible with a wide range of work materials and thread specifications, ThreadMill delivers high-accuracy and high-efficiency threading performance.

Benefits and Features

Feature 1: Improved Machining Stability through Low-Resistance design

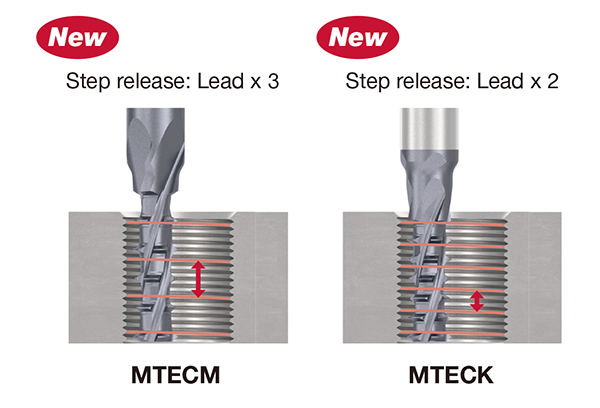

– The step-release structure with spaces between thread crests significantly reduces cutting resistance.

– Lower resistance minimizes tool deflection, contributing to stable thread accuracy.

– The distribution of cutting load extends tool life and enhances surface quality.

Feature 2: Balanced Design for High-Efficiency Machining

– A new design that combines the high productivity of a long cutting edge with the low resistance of a short one.

– Offers high flexibility in cutting conditions, suitable for a wide range of work materials and machining applications.

– Enables stable cutting even under high feed rates, contributing to reduced cycle times.

Feature 3: Realization of High-Precision Thread Machining

– Optimized tool rigidity ensures dimensional accuracy of thread geometry.

– Suppresses vibration during machining to improve surface uniformity.

– Enables stable, high-precision thread machining, reducing the burden on subsequent processes.