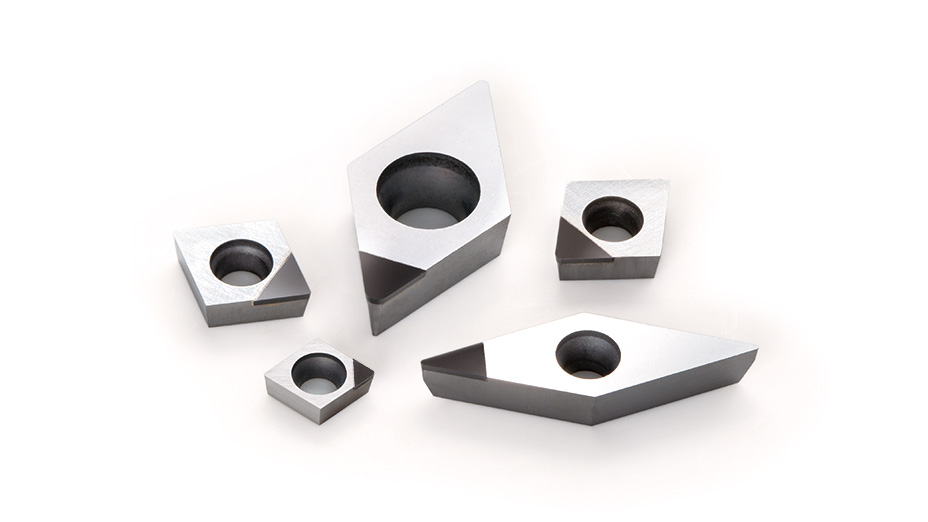

Iwaki, Japan – November, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DX200 lineup, featuring 100% diamond grade inserts for enhanced wear resistance and impurity control. The new lineup includes six insert shapes (CCGW04, CCGW06, CCGW09, DCGW07 DCGW11, VCGW11) specifically designed for small inner diameter machining from a minimum diameter of ø5mm, meeting the demands of high-precision, non-ferrous metal machining.

Challenges and Trends

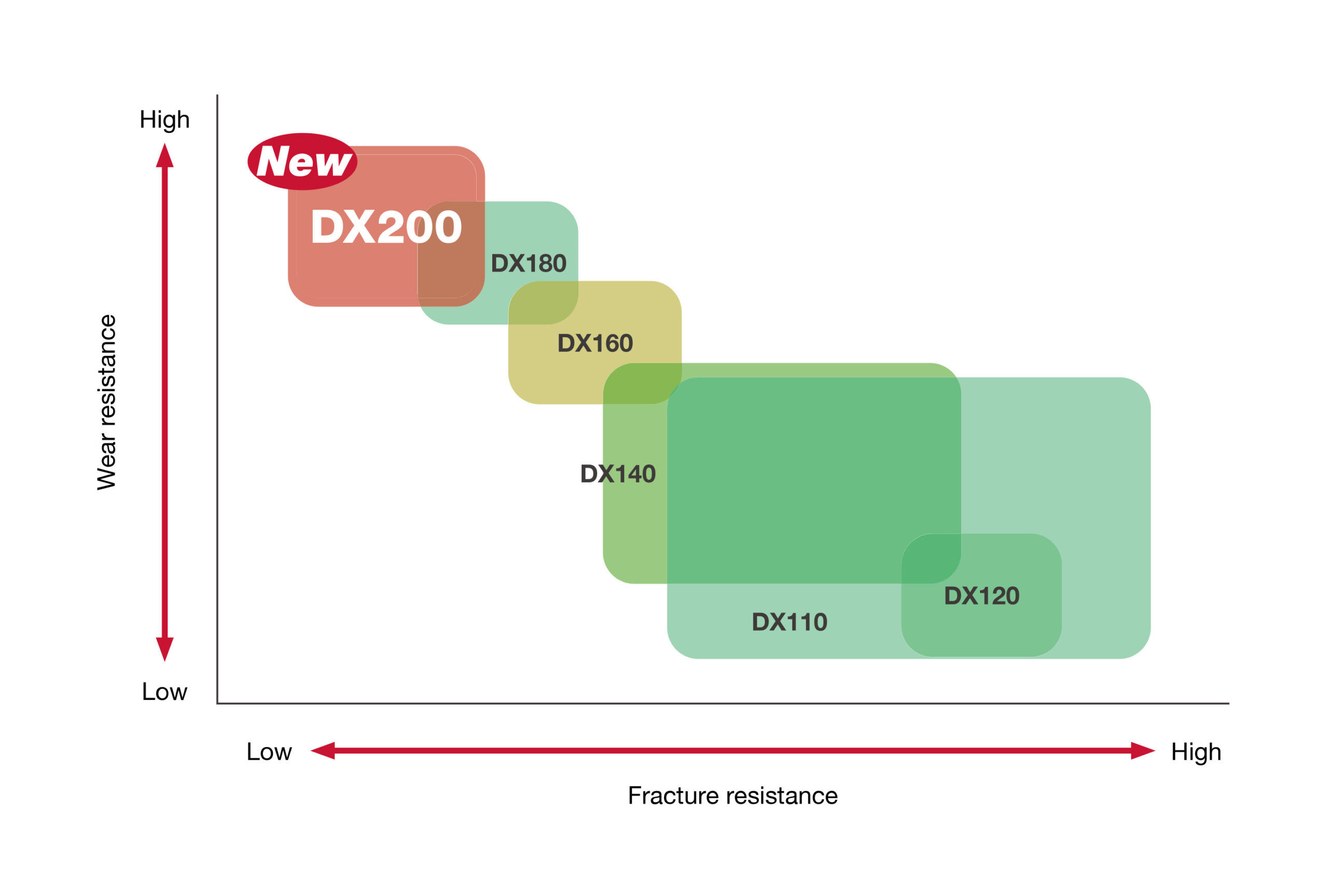

In the machining of high-hardness materials such as cemented carbide, MMC (metal matrix composites), FRP, and CFRP, conventional PCD grades have faced several problems. Specifically, PCD contains binders such as Co (cobalt), which can reduce material hardness, leading to insufficient durability in applications where high wear resistance is critical.

Additionally, in the semiconductor industry, the strict control of impurities has posed challenges, as tools containing Co are often restricted.

In response to these challenges and market conditions, the 100% diamond grade DX200 was developed; however, its shape lineup was limited, prompting the need for further expansion.

Product Overview

DX200 is a 100% diamond turning insert specifically designed for machining high-hardness non-ferrous metals.

It is suitable for machining high-hardness materials such as cemented carbide, carbon, ceramic, and semiconductor target materials.

Compared to conventional PCD grades, it offers superior wear resistance and fracture toughness. DX200 can handle a wide range of machining operations, from continuous to interrupted cutting.

Benefits and Features

Feature 1: High Wear Resistance with 100% Diamond Material

DX200 adopts a binderless 100% diamond material, achieving exceptionally high wear resistance.

This significantly extends the tool life, especially when machining high-hardness non-ferrous metals.

Additionally, the binderless structure prevents contamination from impurities during machining, thus enhancing the quality of the finished product.

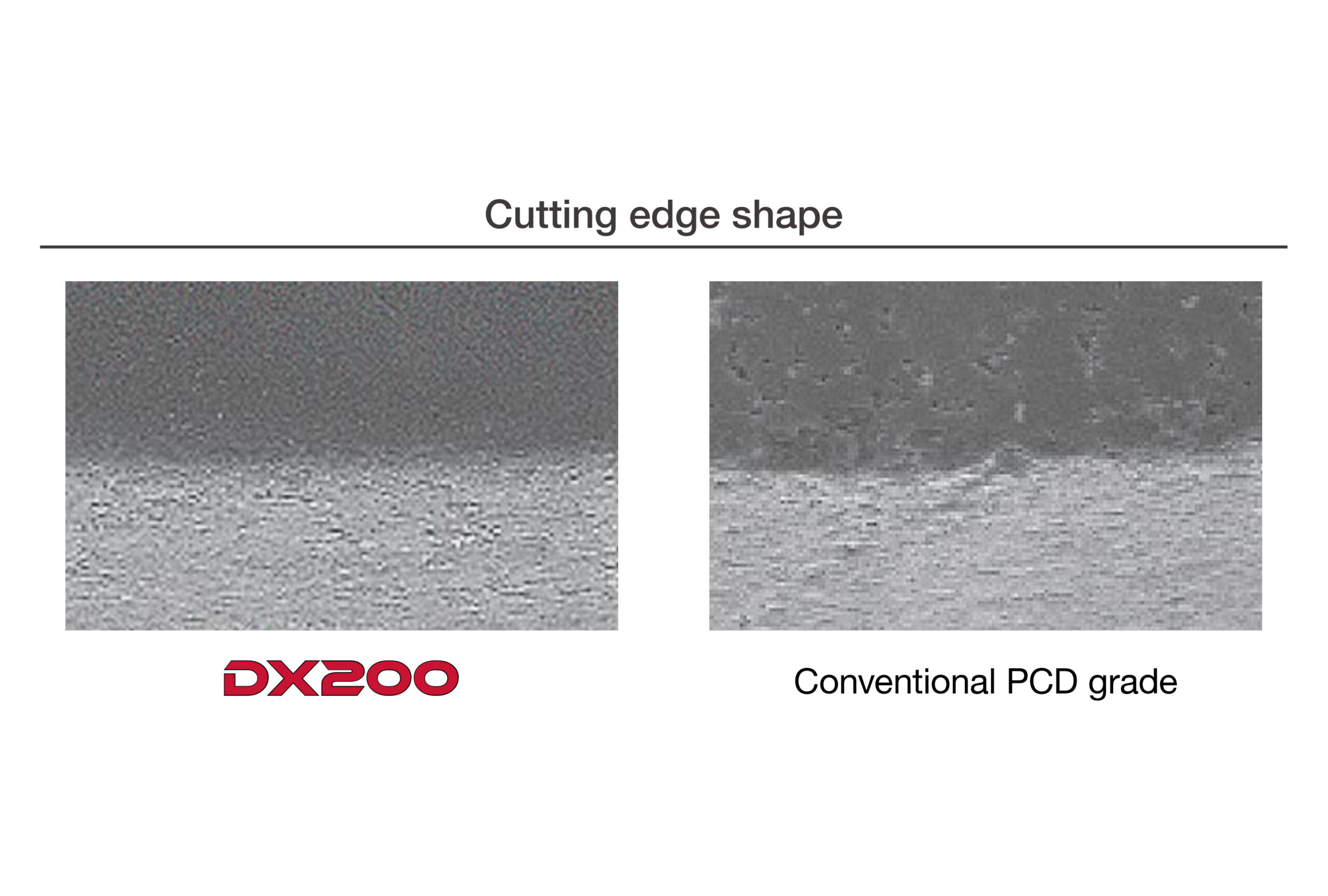

Feature 2: Sharp Cutting Edge for Superior Surface Finish

Utilizing a special grinding technology, the sharp cutting edge ensures an extremely smooth surface finish.

This improves the precision of finishing processes and reduces the need for additional post-processing work.

Even in small internal diameter machining, it delivers excellent cutting performance, providing consistent and stable machining quality.

Feature 3: Versatility in Various Machining Applications

With the expansion of insert shapes, it is now possible to perform small internal diameter machining starting from a minimum diameter of ø5mm.

A wide variety of insert shapes, such as CCGW, DCGW, and VCGW, are available to meet diverse machining needs.

This allows for optimal tool selection based on specific machining conditions, thereby improving machining efficiency.

Cutting Performance

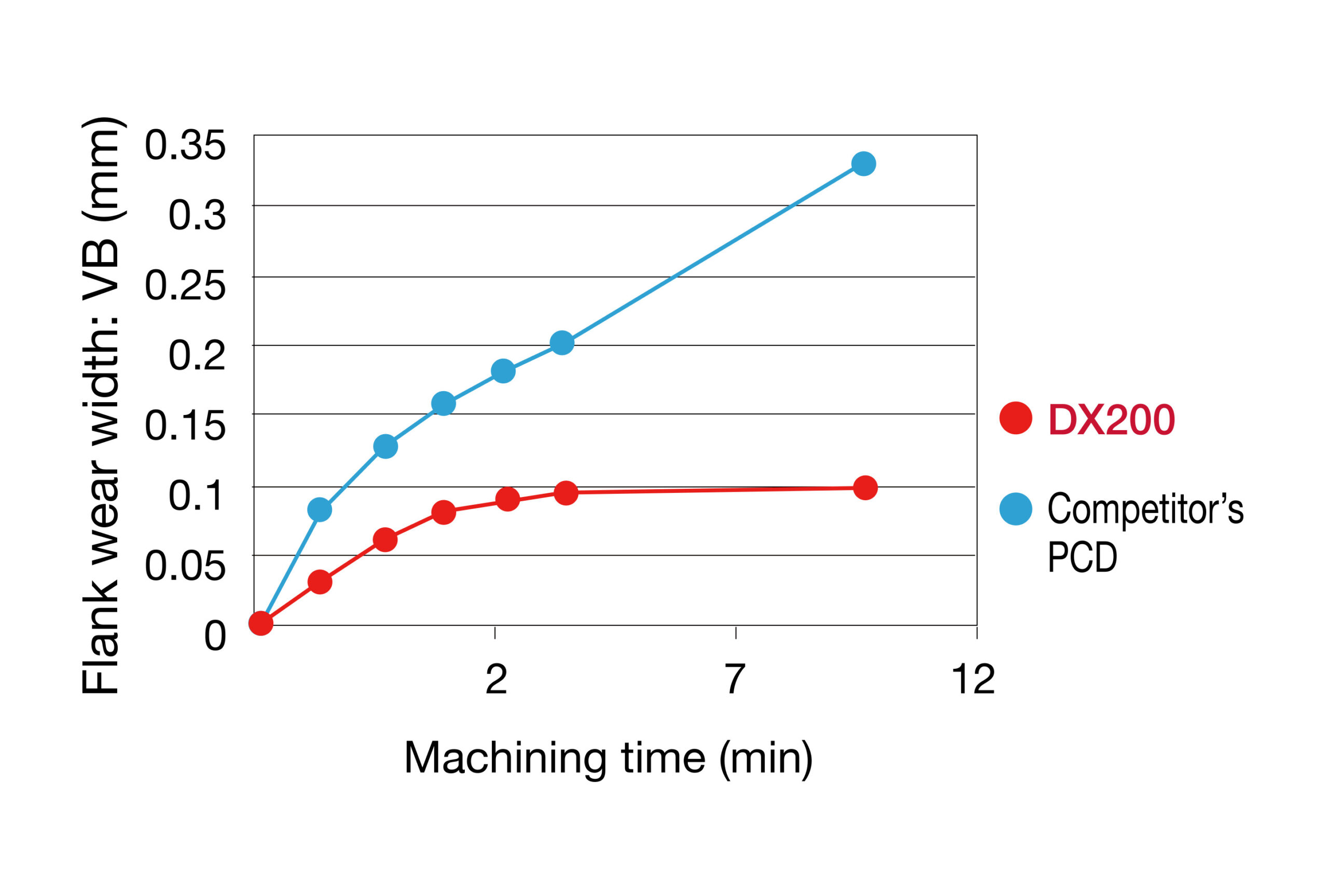

Tool Life Comparison

| Insert | 1QP-DCGW11T304F DX200 |

| Workpiece material | Tungsten carbide (85HRA) |

| Cutting speed | Vc = 20 m/min |

| Feed | f =0.1 mm/rev |

| Depth of cut | ap = 0.1mm |

| Coolant | Wet |

DX200 provides better wear resistance than competitor’s

PCD grade.

Success Stories

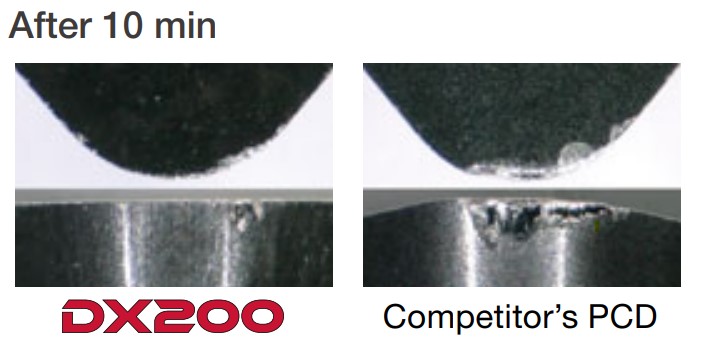

IMPROVED TOOL LIFE

The high-hardness DX200 PCD grade exhibited minimal wear during carbide rod machining, achieving three times tool life compared to competing PCD grade.

| Industry | Engineering |

| Component | Rod |

| Material ISO code | |

| Work material | Carbide |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | Internal threading |

| Product name | DX200 |

| TSR No. | 5067T |