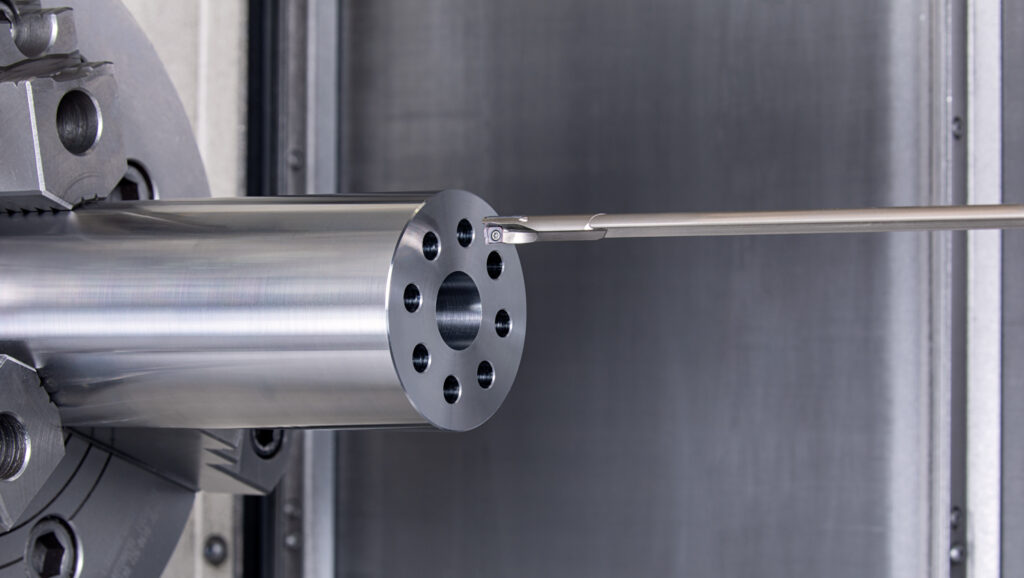

Iwaki, Japan – March, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DeepTriDrill series, now available in a minimum diameter of ø8 mm—the smallest in the industry. This expansion includes 16 drill body variants, two insert options, two guide pads, and an adjustable shim set, providing enhanced flexibility for deep hole drilling in mold and automotive manufacturing.

Challenges and Trends

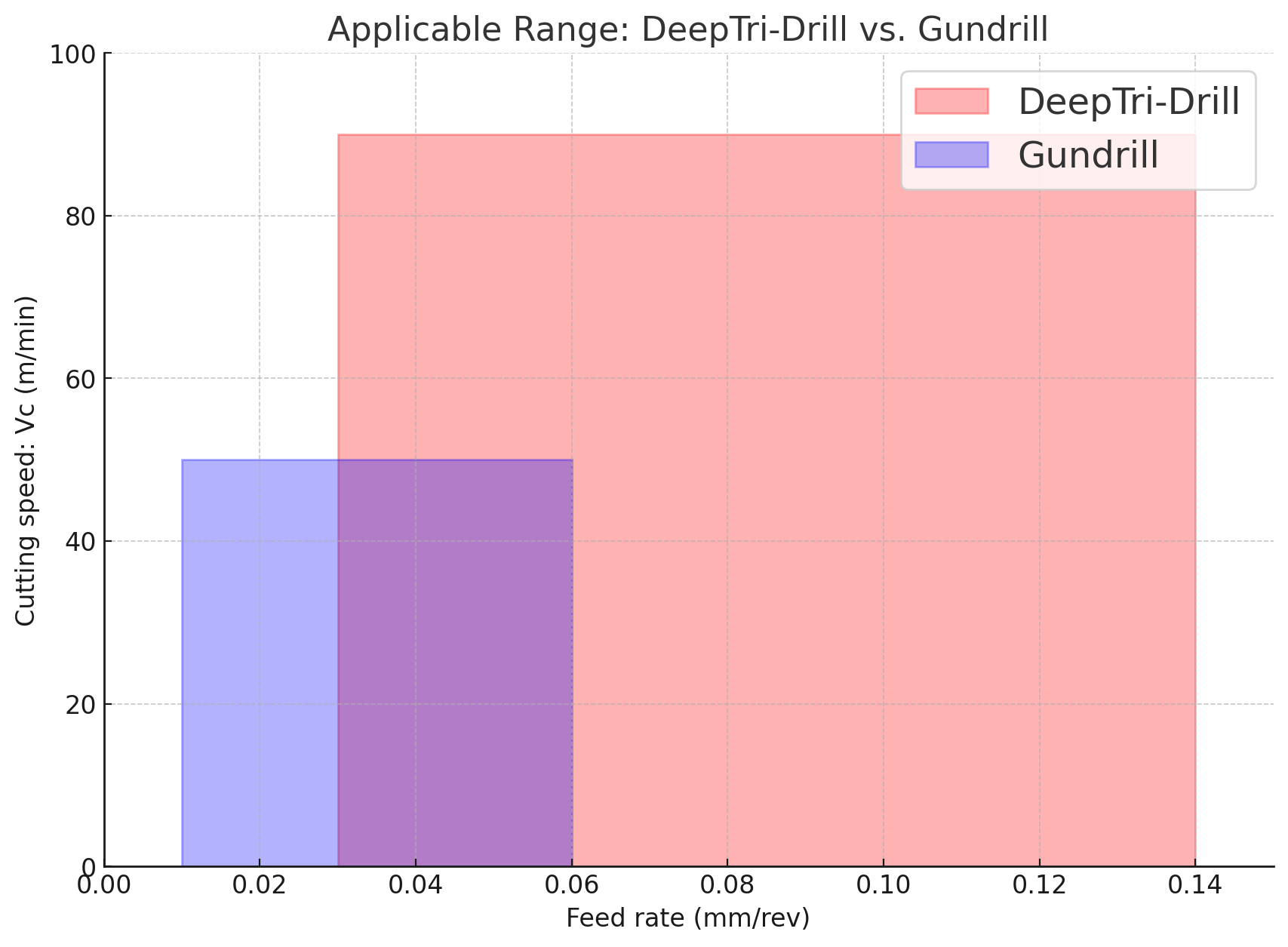

In the mold and automotive industries, deep hole machining is indispensable. Specifically, high-precision and efficient machining is required for cooling holes in molds and deep holes in shafts. However, conventional brazed gun drills require regrinding, making tool management cumbersome and hindering productivity improvement. Additionally, their low machining efficiency often creates bottlenecks in production lines. Given these challenges, there is a growing demand for tools that offer high efficiency and easy management.

Product Overview

DeepTriDrill is a high-performance deep hole drilling tool offered by Tungaloy. Its indexable design allows for easy tool management while ensuring stable and highly efficient machining. With a wide lineup that includes small-diameter options, it can accommodate various deep hole drilling applications. Utilizing BTA tool technology, DeepTriDrill delivers excellent roundness, straightness, and surface finish. Compared to conventional brazed gun drills, it achieves twice the machining efficiency.

Benefits and Features

Feature 1: High-efficiency machining with the industry’s smallest indexable gun drill (ø8 mm)

The DeepTriDrill, with a minimum diameter of ø8 mm, is the industry’s smallest indexable gun drill.

Features a unique chipbreaker that generates small, light chips.

Excellent chip evacuation enables high-feed machining.

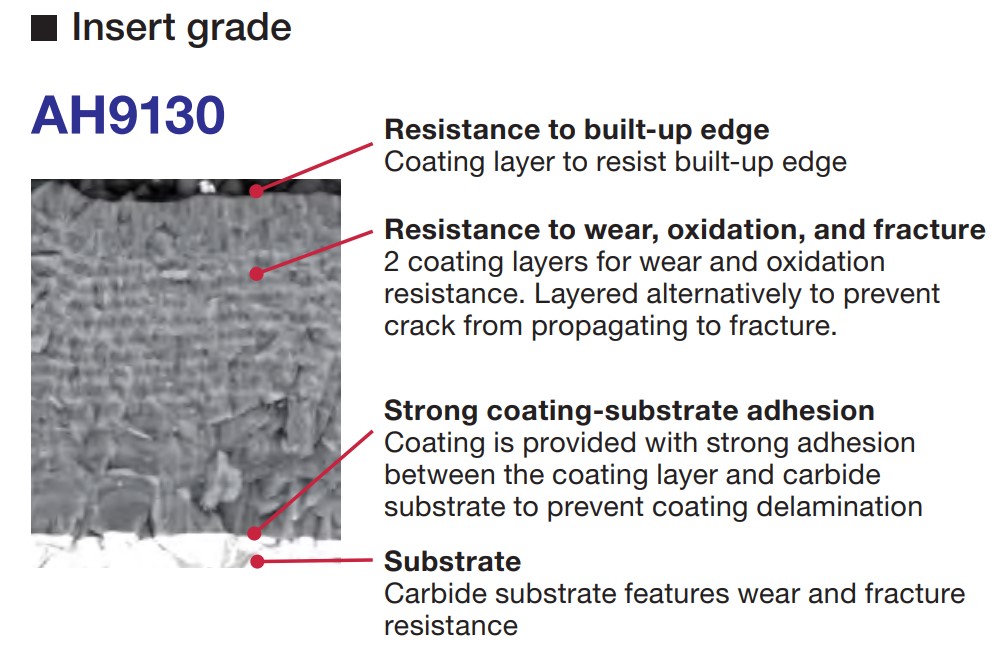

Feature 2:Excellent tool life

Equipped with AH9130, a drill-specific grade with excellent wear resistance.

Compared to conventional brazed gun drills, tool life is significantly improved.

Longer tool life reduces tool change frequency, contributing to increased productivity.

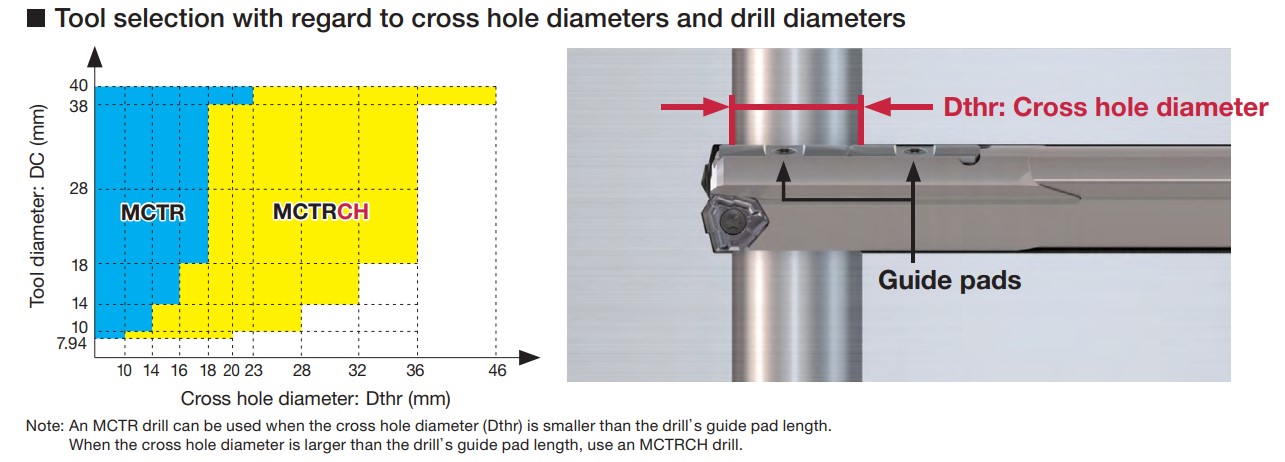

Feature 3: Suitable for cross-hole machining

Dual guide pads ensure stable deep-hole machining, even for cross-hole applications.

Reduces machining issues commonly encountered in mold-making and similar applications.

Enhances reliability in environments requiring high-precision deep-hole drilling.

Cutting Performance

Productivity Comparison: SCM440 / 42CrMo4

| DrillBody | MCTR8.00XM20-20 |

| Insert | ZSGT04 NDJ AH9130 |

| Guide pad | SGP03 FH3125 |

| Workpiece material | SCM440 / 42CrMo4 |

| Machine | #40 horizontal M/C |

| Depth | H=280mm |

| Coolant | Wet(Internal) |

DeepTri-Drill achieves stable machining at 2 to 3 times the efficiency compared to brazed gun drills.

Success Stories

IMPROVED PRODUCTIVITY

DeepTri-Drill provided 14 times productivity gain over competitor’s gun drill. Also eliminated the need for regrinding, simplifying tool management.

| Industry | Die & Mold |

| Component | Die block |

| Material ISO code | P – Steel |

| Work material | S50C |

| Machine(Spindle type) | Horizontal Machining Center |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | DeepTri-Drill |

| TSR No. | 5166D |

IMPROVED PRODUCTIVITY

DeepTri-Drill provided 4.2 times productivity gain over competitor’s HSS drill. Also eliminated the need for regrinding, simplifying tool management.

| Industry | Die & Mold |

| Component | Mold |

| Material ISO code | H – Hardened material |

| Work material | SKD61 |

| Machine(Spindle type) | Horizontal Machining Center |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | DeepTri-Drill |

| TSR No. | 5178D |