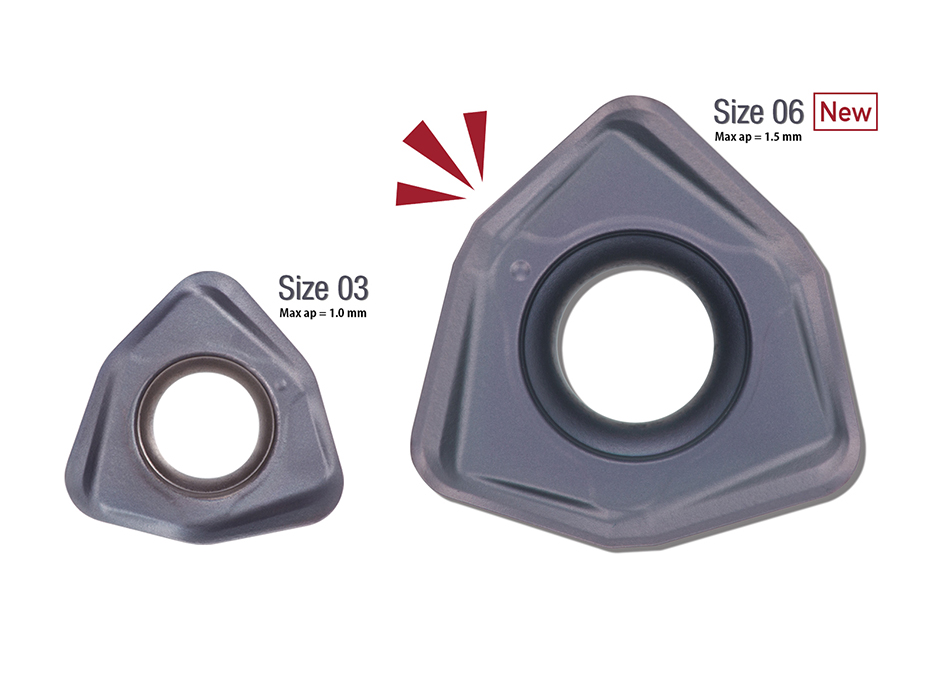

Iwaki, Japan – November, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DoFeedTri series with the addition of larger size 06 inserts, designed for high-feed machining with enhanced stability, tool life, and chatter suppression.

Challenges and Trends

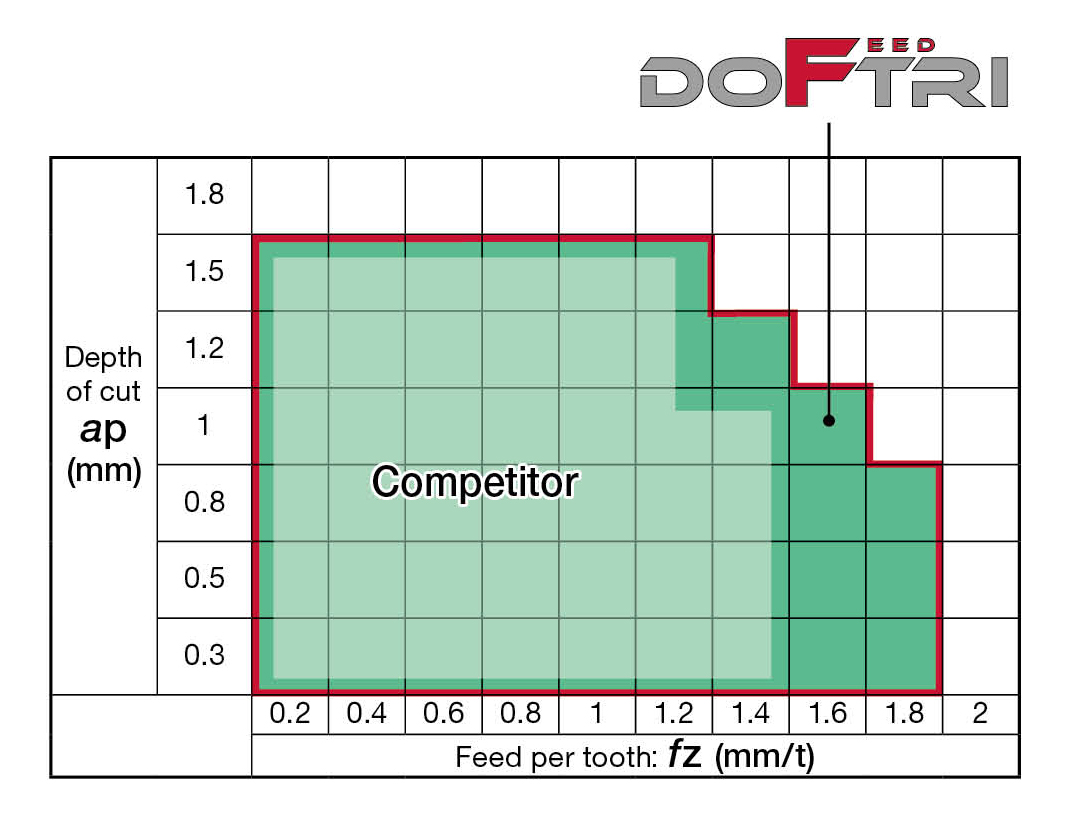

Under the current Challenges and Market Conditions—where high-efficiency machining is required across a wide range of industries such as general machining, mold & die, automotive, construction machinery, and heavy electric equipment—the conventional 6-corner high feed cutters have limitations in productivity, as the depth of cut is restricted to less than 1 mm. This is especially problematic in mold machining, where long tool overhangs tend to cause chatter and vibration, negatively affecting machining accuracy and tool life. Furthermore, in plunge milling operations, chip jamming often leads to cutting edge chipping, making stable machining performance a critical requirement.

Product Overview

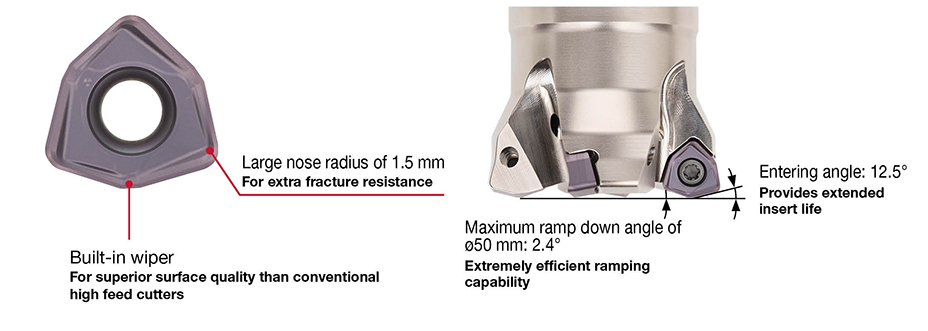

Featuring a high-rigidity design and six-corner inserts, the high-feed cutter “DoFeedTri” is an optimal high-efficiency tool for roughing and ramping operations. With excellent edge strength and a low lead angle, it significantly enhances machining efficiency and tool life.

Benefits and Features

Feature 1: Design for High-Efficiency Machining

– Supports a maximum depth of cut of 1.5 mm, increasing material removal per pass and reducing overall machining time

– The low entering-angle cutting edge enables high-feed machining while suppressing chatter

– Generates thin chips, which helps lower cutting heat and contributes to extended tool life

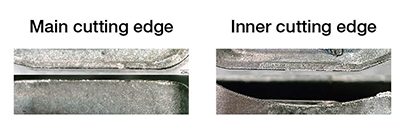

Feature 2: Excellent Cutting Edge Strength and Stability

– Large corner radius distributes impact on the cutting edge, improving chipping resistance

– Reverse rake relief face enhances edge support rigidity, ensuring stable machining even during heavy or interrupted cuts

– Enables long continuous machining with minimal edge chipping, even under conditions where chip accumulation tends to occur

Cutting Performance

■ Comparison with face milling

| Cutter | TXWX06M050B22.0R04 (ø50 mm, CICT = 4) |

| Insert | WXMU0605ZER-MM AH3225 |

| Workpiece | S55C / C55 |

| Cutting speed | Vc = 200 m/min |

| Width of cut | ae = 35 mm |

| Overhang | 75 mm |

| Coolant | Internal air |

| Machine | Vertical M/C, BT50 |

| Criteria | Chattering |

DoFeedTri features a rigid tool design and small entering angle, catering to a wide range of applications.

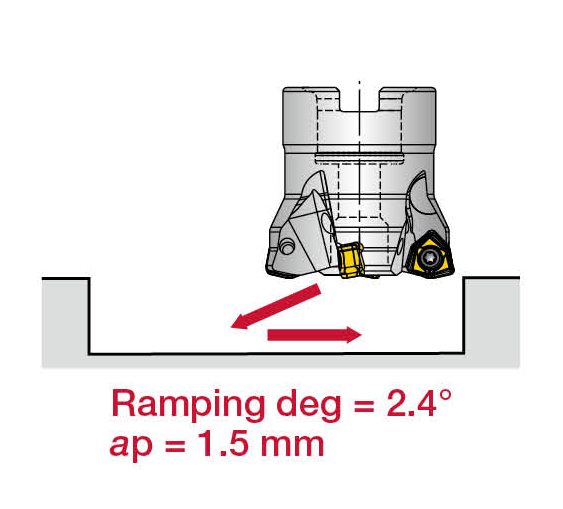

■ Ramping operations

| Tool diameter | ø50 mm, CICT = 1 |

| Workpiece material | NAK80 |

| Cutting speed | Vc = 120 m/min |

| Feed per tooth | fz = 0.7 mm/t |

DoFeedTri eliminated premature failure due to chip re-cutting when machined aggressively with the maximum D.O.C. at ramp down angle, providing stability and reliability.

Success Stories

IMPROVED TOOL LIFE

Incorporating the inserts with a small entering angle and rigid tool design, DoFeedTri provided 1.2x tool life increase.

their built-in wiper provided excellent surface quality.

| Industry | Engineering |

| Component | Bridge Parts |

| Material ISO code | |

| Work material | SS400 |

| Machine(spindle type) | Tower Machining Center (#50, BT50) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoFeedTri |

| TSR No. | 5448M |

IMPROVED TOOL LIFE AND PRODUCTIVITY

Extremely rigid, DoFeedTri eliminated crack generation on the cutting edges during heavy-interruptedcuts, providing process security.

| Industry | Engineering |

| Component | Union nut |

| Material ISO code | |

| Work material | SKD11 |

| Machine(Spindletype) | Vertical Machining Center (#50,BT50) |

| Tool family | Milling |

| Toolcategory | Face milling |

| Product name | DoFeedTri |

| TSR No. | 5449M |