Digital Adjustment with Zero Backlash Enables Intuitive Operation for Both Novices and Veterans

Precision Shouldn’t Be a Struggle

In boring operations, even the smallest misstep can compromise dimensional accuracy, surface finish, and overall productivity. For many operators, especially those less experienced, manual tool adjustments can feel like navigating a maze—frustrating, error-prone, and time-consuming.

Common issues include :

- Backlash from torque release when using a wrench, making it nearly impossible to position the tool precisely.

- Tiny, hard-to-read scales, leading to visibility errors and inconsistent results.

- Complex fine-tuning that requires experience and practice to master—creating barriers for novice users.

These factors not only slow down setup times but can also lead to rework, quality defects, and production losses.

SwissBore: Making Precision Accessible

SwissBore was developed to break through these barriers, providing a digital boring system that’s fast, precise, and intuitive—whether you’re a seasoned machinist or a newcomer to the shop floor.

Here’s how it changes the game:

1. Zero-Backlash Adjustment for Accurate Results

Forget the frustration of backlash. SwissBore features a digital fine adjustment mechanism that displays values in 0.001mm increments—eliminating guesswork and ensuring accurate tool positioning every time.

✅ Even novice operators can now make confident, precise micro-adjustments without fear of over- or under-shooting.

2. Easy-to-Read Digital Display for Mistake-Free Setup

Conventional analog scales are hard to read—and easy to misread.

SwissBore solves this with a large, high-visibility numeric display, allowing users to check adjustment values at a glance.

✅ Better visibility = fewer errors, faster setup, and greater peace of mind.

3. Simple, Smart Operation with Modular Flexibility

The digital display unit is lightweight, dustproof and waterproof, and only needs to be installed during adjustment—keeping your setup lean and clean.

Its modular system allows compatibility with multiple boring heads, insert holders, and adapters, covering a wide range of boring diameters.

✅ SwissBore adapts to your needs, not the other way around.

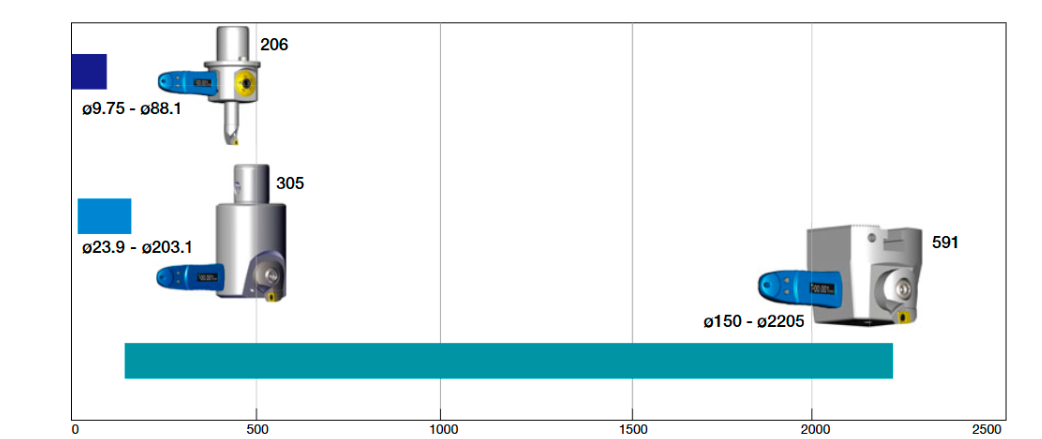

A Range That Covers It All

SwissBore supports hole diameters from ø9.75 to ø2205, with a wide selection of boring bars and cartridges available for diverse applications and materials.

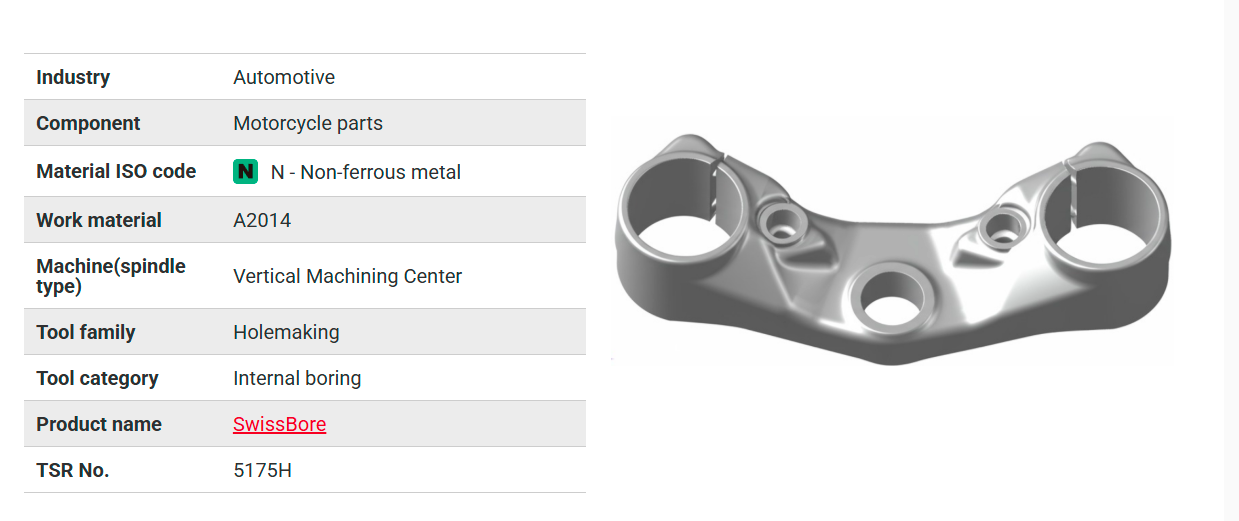

Real-World Results: Faster Setup, Higher Productivity

Application Example: In the production of motorcycle engine parts made from aluminum alloy, traditional boring tools with dial adjustments caused significant machine downtime during fine diameter tuning.

After switching to SwissBore, operators could:

- Perform quick, repeatable micro-adjustments

- Reduce setup time drastically

- Improve machine utilization and throughput

✅ Result: Greater productivity, less stress, and consistent quality.

Final Thoughts

SwissBore isn’t just about digital convenience—it’s about empowering every operator to work with confidence, precision, and speed. Whether you’re new to boring operations or a veteran looking to streamline your process, SwissBore delivers barrier-free machining with measurable performance gains.