From HSS Drills to a Smarter Solution: Exploring DrillForce-Meister

For decades, HSS drills have been the go-to solution in can manufacturing and for machining irregular workpieces. Their flexibility and lower cost made them the preferred choice when dealing with unstable clamping, rough surfaces, and vibration-prone machining environments. However, the landscape is changing rapidly, and relying on HSS drills is becoming increasingly inefficient.

The Decline of HSS Drills: Rising Costs and Performance Limitations

Many manufacturers are now moving away from HSS drills due to multiple challenges:

✅ Soaring costs – Prices for HSS drills have increased significantly.

✅ Longer lead times – Regrinding takes time and raises overall costs.

✅ Declining quality – A shortage of skilled craftsmen impacts regrinding consistency.

✅ Lower efficiency – With competition intensifying, manufacturers need faster, more reliable machining solutions.

DrillForce-Meister: The Next-Generation Solution

DrillForce-Meister is designed to solve these challenges, offering a cost-effective, high-performance alternative to HSS drills. With a unique head-exchange mechanism, superior clamping rigidity, and versatile machining capabilities, it brings a new era of productivity.

Why Switch to DrillForce-Meister?

1. Lower Costs & Increased Reliability with a Head-Exchange System

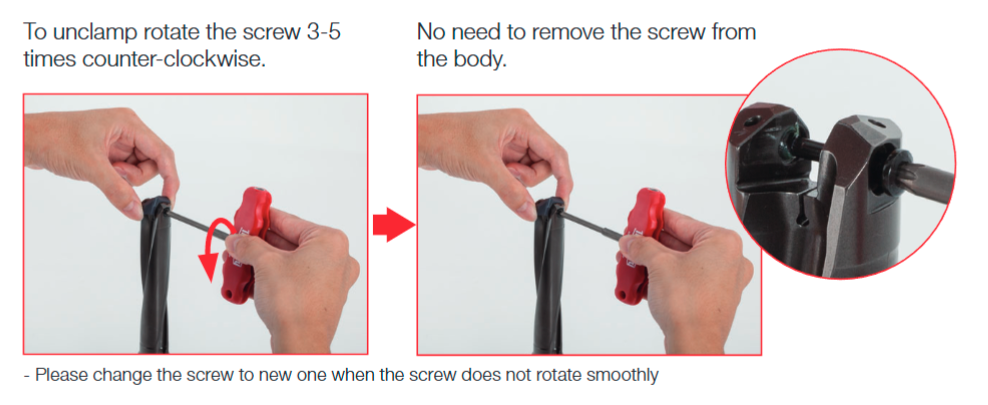

Unlike traditional carbide drills, DrillForce-Meister features a replaceable head, allowing quick and easy tool changes without removing the drill body. This eliminates downtime and removes the need for regrinding, lowering operational costs.

Key Benefit: Reduces tool change time and eliminates costly regrinding.

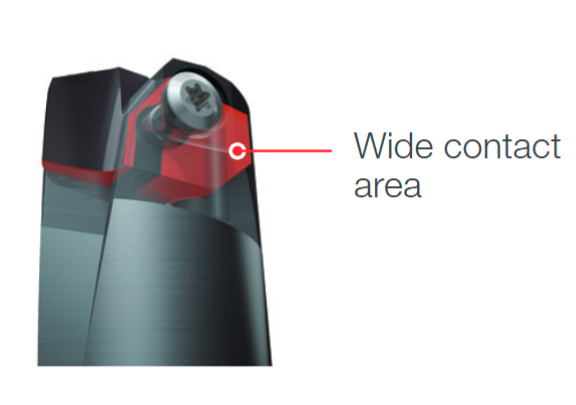

High Clamping Rigidity – The drill head and body have an extensive contact surface, ensuring exceptional stability even in large-diameter hole machining. This significantly reduces the risk of chipping or tool breakage.

2. Versatility for Various Machining Needs

DrillForce-Meister offers multiple head types to handle different machining challenges, ensuring high precision across different applications.

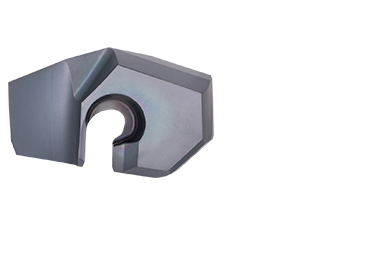

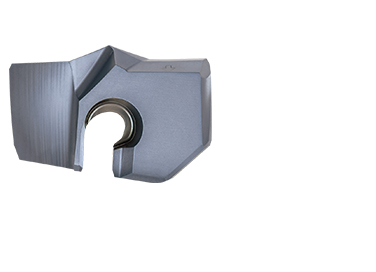

SMC (ø26 – ø33 mm)

Features a two-stage tip angle and quick centering design, eliminating the need for guide holes, even for deep machining (L/D=8).

3. Handles Large Diameters and Deep Hole Machining

DrillForce-Meister is engineered for deep-hole applications, expanding drilling capabilities beyond HSS limitations.

- Large-diameter hole machining from ø20mm to ø41mm.

- L/D=8 deep hole drilling for high-precision performance.

Real-World Success: How DrillForce-Meister Boosts Productivity

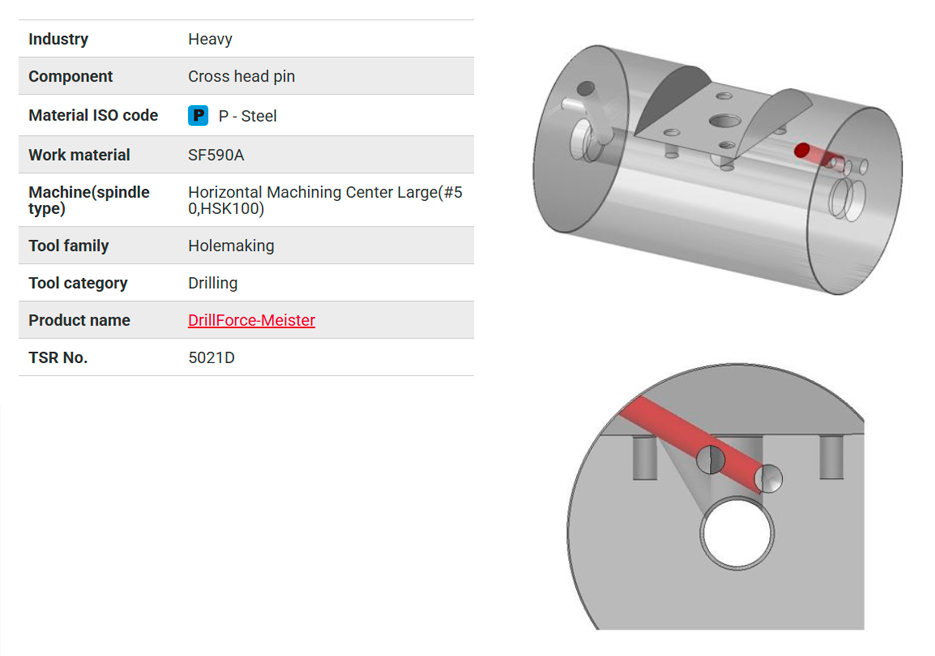

Case Study 1: Cutting Machining Time by 80%

Challenge:

A manufacturer using HSS drills in cross-hole machining struggled with low machining efficiency and excessive tool wear.

✅ Solution:

By switching to DrillForce-Meister (3xD and 8xD tools), they leveraged the high rigidity of the body and secure head clamping to significantly improve performance.

Result: Machining time reduced by 80%, despite intermittent cutting conditions.

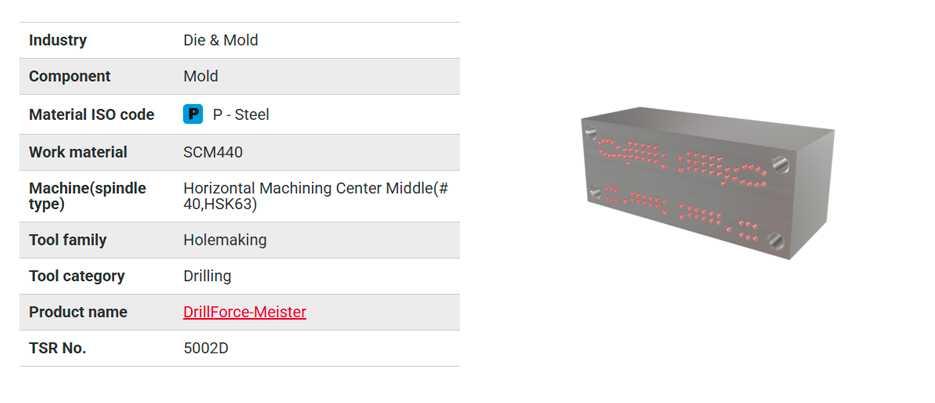

Case Study 2: 6.5x Higher Machining Efficiency

Thanks to its advanced cutting-edge geometry and excellent chip evacuation, DrillForce-Meister achieves up to 6.5 times the machining efficiency of HSS drills.

Key Takeaway: Faster machining = lower costs = higher productivity.

Conclusion: A Smarter Alternative to HSS Drills

As manufacturing evolves, so do the demands for higher efficiency, precision, and cost-effective solutions. While HSS drills have long been a staple, many manufacturers are now seeking alternatives that reduce downtime, improve consistency, and optimize machining processes.

DrillForce-Meister offers a practical solution by combining reliability, performance, and flexibility, making it a strong candidate for those looking to upgrade their drilling operations.

Key Advantages:

✔ Reduces tool change time with a head-exchange system

✔ Enhances machining efficiency and precision

✔ Extends tool life, lowering long-term costs

✔ Handles a wide range of applications

As machining challenges grow, exploring new solutions can lead to significant improvements in productivity and cost savings.