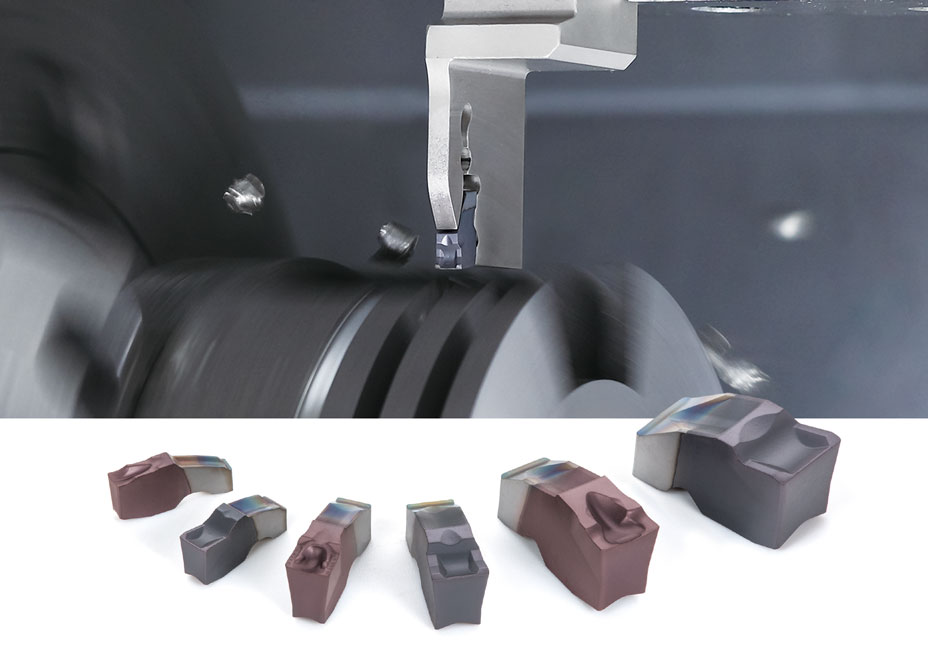

Iwaki, September 2023— Tungaloy has announced the expansion of its AddForceCut grooving and parting tool system. The expansion incorporates new inserts designed for cutting widths of 6 and 8 millimeters. Additionally, Grade AH6235 is now available across all insert sizes and geometries to meet the requirements for added insert fracture toughness.

AddForceCut uses a unique insert clamping solution that makes a single-ended insert self-locked into the insert seat, enabling a secure process and effective chip evacuation during parting and deep grooving operations. The insert seat has three location points – one on the top clamp and two on the bottom – that fix the insert in place while ensuring rigidity and accuracy. Also, the bottom clamp has a stopper point that sustains such cutting forces generated as deep grooving or parting of up to 120 millimeter (4.724 inch) diameter bar stocks.

AddForceCut offers three insert geometries: QGM is the first-choice geometry for a range of materials and applications, QGS features a sharp cutting edge that generates light cutting action, and QTX is designed specifically for facing operations.

The QGM and QGS insert lines have been expanded with 6 and 8 millimeter cutting widths, enabling the inserts to cover grooving widths of 2, 3, 4, 5, 6, and 8 millimeters.

Developed to enhance the inserts’ fracture toughness, AH6235 grade is now available for all AddForceCut insert sizes and geometries. The grade contributes to the prevention of edge chipping, while promoting tool life longevity and predictability, during challenging parting and deep grooving operations including machining through interruptions.

Product information

No. 543S3-G (Metric)