HIGH-FEED

MILLING

the Go-to Solution for Accelerated Machining

HOW IT WORKS?

High-Feed Milling Mechanism

First utilized in the Die and Mold industry, High-Feed Milling is a milling method that pairs shallow depth of cut (DOC) with high feed rate up to 0.008" per tooth to maximize the amount of metal being removed from a part, resulting in more parts being machined more quickly.

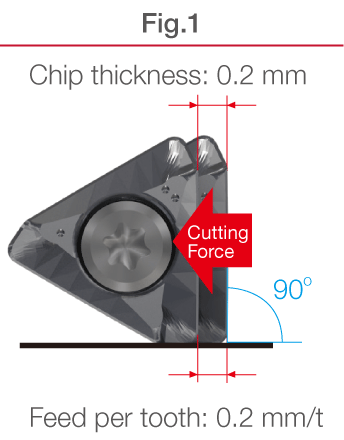

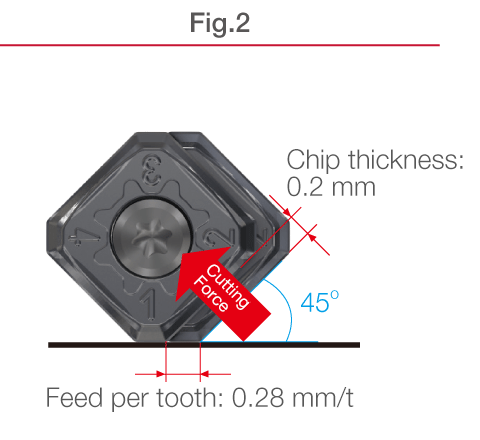

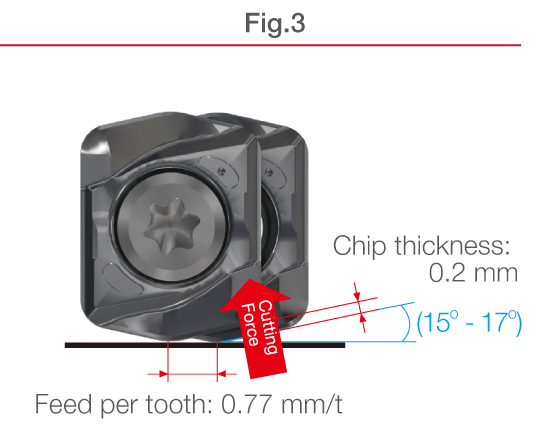

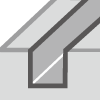

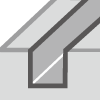

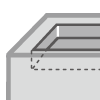

The HFM mechanism is based on the “chip thinning” effect. Chip thinning depends on the lead angle of a milling cutter. A cutter with a 90° lead angle has no benefit of chip thinning as 0.008" of feed per tooth only delivers the same 0.008" of chip thickness (Fig. 1). In the case of a cutter with a 45° lead angle, a 0.011" of feed per tooth creates a 0.008" of chip thickness (Fig. 2) which allows the feed to be increased, resulting in reduced cycle time. Fig. 3 shows the chip thinning effect of DoFeed, Tungaloy’s best selling HFM line, where a 0.030" of feed per tooth provides chip thickness of only 0.008", and cycle time is typically decreased by 50% or more.

Low cutting force is also an advantage of HFM. The lead angle on a cutter decides the direction of the cutting force. A 90° cutter (Fig. 1) will produce cutting force that acts perpendicular to the spindle, putting incredible pressure on the tool. As for a 45° cutter (Fig. 2), cutting force acts against the spindle at a 45° angle. With DoFeed, cutting force is almost parallel, and directed back to the spindle due to its acute lead angle (Fig. 3), which means less pressure on the spindle.

TOOL SELECTION GUIDE

Choose the applications to find the right tool

| ★: Most suitable ☆: Suitable ★: Usable |

TungForceFeed | DoFeed | MillQuadFeed | DoTwistBall | DoFeedQuad | TungMeister | |

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

| Tool diameter | ø8 - ø25 | ø16 - ø200 | ø25 - ø160 | ø20 - ø63 | ø50 - ø125 | ø10 - ø20 | |

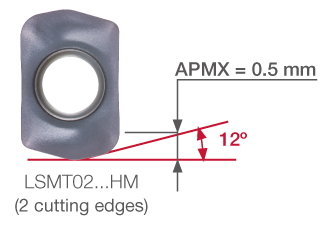

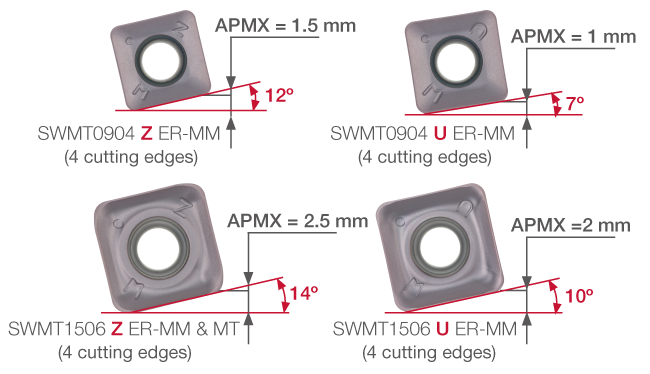

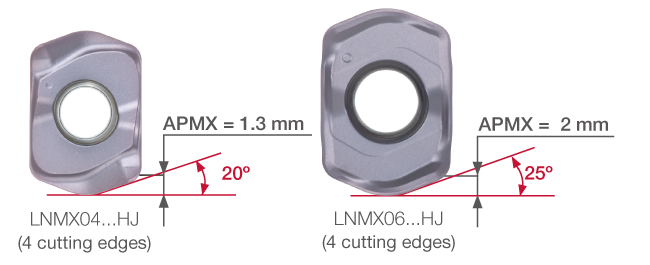

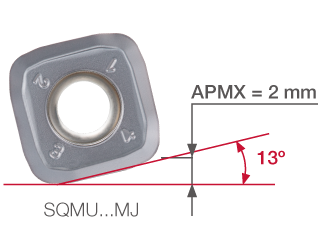

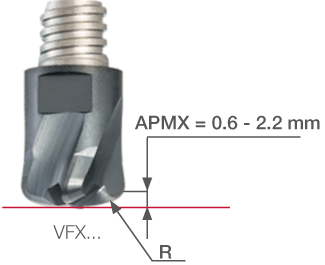

| Depth of cut (APMX) | 0.5 | 1 / 1.5 | 1 / 1.5 / 2 / 2.5 | 1.3 / 2 | 2 | 0.6 - 2.2 | |

| Entry angle | 12º | 17º / 15º | 7º / 12º / 10º / 14º | 20º / 25º | 13º | R | |

| No. of corners (insert) | 2 | 4 | 4 | 4 | 8 | 1 | |

| Spindle size | BT30 / SK30 / CAT30 |

||||||

| BT40 / SK40 / CAT40 |

|||||||

| BT50 / SK50 / CAT50 |

|||||||

| Applications | Facing |

☆ | ★ | ★ | ☆ | ☆ | ★ |

Shouldering |

☆ | ★ | ☆ | ☆ | ☆ | ||

Shouldering R |

★ | ★ | |||||

Slotting |

☆ | ★ | ★ | ★ | ★ | ||

Slotting R |

★ | ★ | |||||

Profiling |

☆ | ☆ | ☆ | ☆ | ★ | ||

Pocketing |

☆ | ★ | ☆ | ★ | ☆ | ||

Ramping |

☆ | ★ | ☆ | ★ | ☆ | ||

Plunging |

★ | ☆ | ★ | ☆ | ★ | ||

Long overhang |

☆ | ☆ | ★ | ★ | ☆ | ☆ | |

Interrupted surface |

☆ | ☆ | ★ | ☆ | ☆ | ★ | |

Thin workpiece |

☆ | ★ | ★ | ★ | ★ | ☆ | |

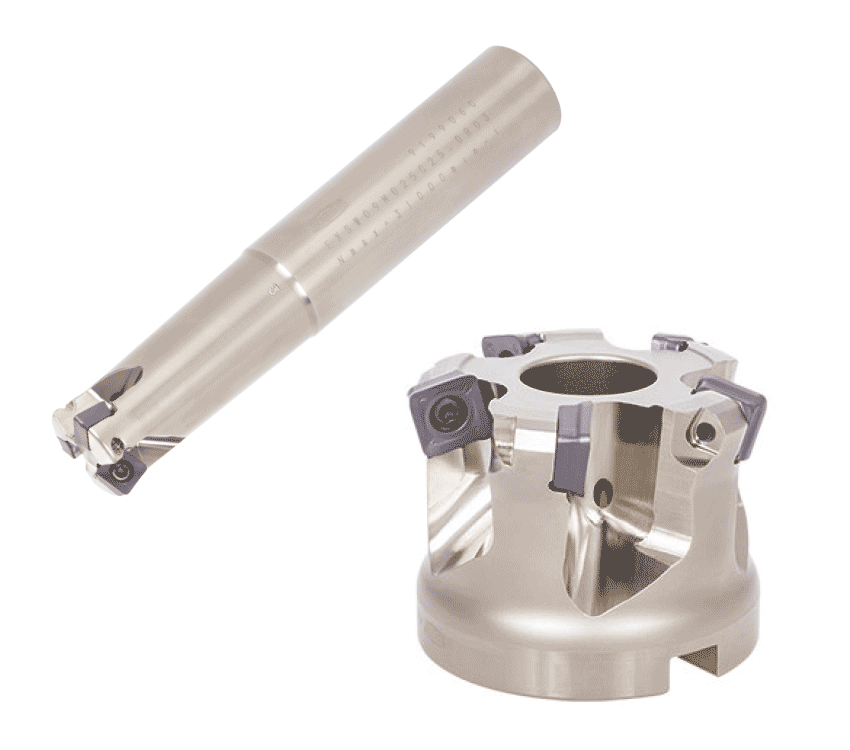

HFM cutter with robust design in small diameters

- - Strong insert corner for high-feed operations

- - Incredible productivity thanks to extra close-pitch tool

- - R2 round insert is also mountable

- - Maximum feed rate: 0.031 ipt

Versatility at its finest

- - Perfect for ramping, plunging, hole enlarging, slotting, drilling, and shoulder milling in a wide range of industries

- - Smooth chip evacuation and minimal chattering

- High productivity due to close-pitch design

- - Maximum feed rate: 0.059 ipt

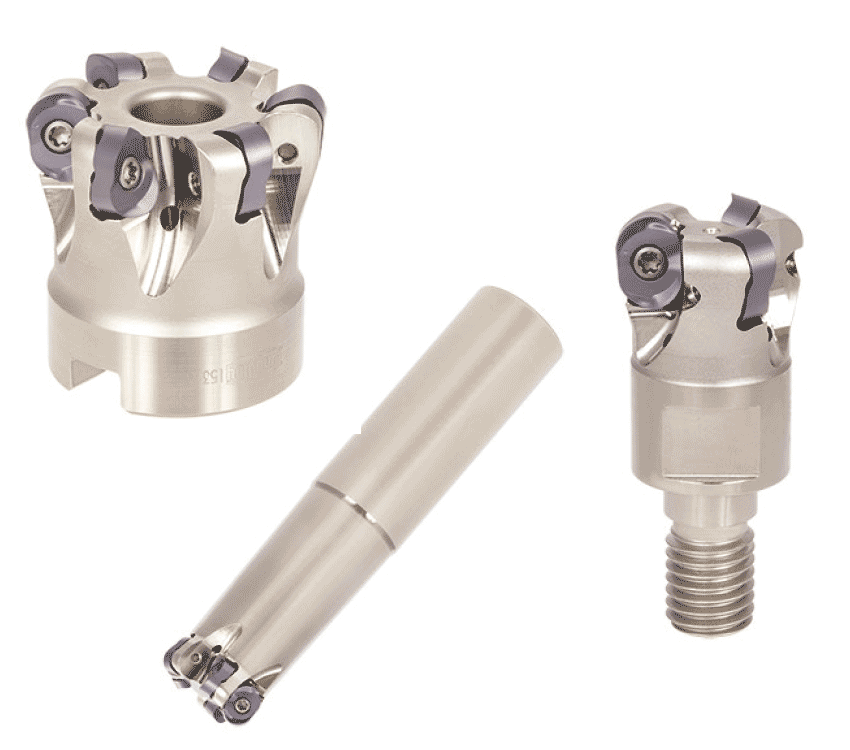

Highly versatile series with the unique insert design that allows changing entry angles

- - Two types of inserts fit on one cutter body, providing two different entry angles

- - ZER type: For general application with low cutting force

- - UER type: Suitable for difficult-to-cut materials and long overhang machining

- - Maximum feed rate: 0.079 ipt

Unique twist on the insert ensures stability and maximizes productivity

- - R4,5,6 round inserts are also mountable

- - High machining efficiency with 30% greater D.O.C

- - Maximum feed rate: 0.051 ipt

Economical tool for rough operations

- - Dovetail clamping prevents inserts from lifting up during heavy roughing operations

- - Maximum feed rate: 0.079 ipt

VFX

VFX

Indexable solid carbide head

- - Highly accurate repeatability

- - Drastically reduces tool changeover time

- - Maximum feed rate: 0.040 ipt